Search by Issue or Need

- For improved

processes -

Easy peeling

Easy peeling

Automation

Automation

Shorter processes

Shorter processes

Low contamination

Low contamination

- For cost

reduction -

Easy peeling

Easy peeling

Improved yield rates

Improved yield rates

Reduced waste

Reduced waste

performance

environment

For improved processes

Easy peeling

Peeling capability without leaving any adhesive residues while maintaining strong adhesion

We have products capable of responding to your needs such as in the following situations:

- You just want to remove the tape and remake products when an abnormality is found in a product inspection

- You want to easily remove the tape after protecting devices in a heating process, such as a reflow process, during the manufacture of various packages

- You want to easily remove the tape after secure bonding or fixing during the grinding process

- You want to disassemble LCD and OLED panels without scratching the panel surface during repair

_易解体・易剥離フォームテープ_png_w500px_h500px.png)

Easy-to-Dismantle/Easy-to-Remove Foam Tape

A reusable flexible foam tape that combines strong holding power with reworkability

_光学フィルム用プロテクトテープ_png_w500px_h500px.png)

Protective Tape for Optical Films 67/68/6900 Series

A high-performance protective tape that minimizes substrate contamination and prevents the beauty of optical films

_研磨布固定用両面テープ_ダブル_png_w500px_h500px.png)

Double-sided Tape for Fixing Polishing Pads

A double-faced tape with a differential design that provides excellent adhesion and easy removability

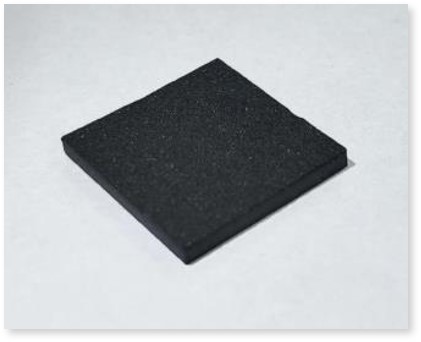

_防水・衝撃吸収フォームテープ 5200_png_w500px_h500px.png)

Waterproof/Shock-Absorbing Foam Tape 5200 Series

A heat-resistant foam tape that delivers both waterproofing and shock absorption

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

_高遮光高反射両面テープ 3800_png_w500px_h500px.png)

Double-sided adhesive tape 3800 series for fixing LCD components

Double-sided tape for fixing LCD parts

Automation

Development of production lines free from human errors

We have products that enable you to solve such problems as the following:

- Fostering skilled workers

- Formulating measures against human errors

- Improving microfabrication technology

- Remotely checking production lines

- Unstable communication even with the 5G environment in place

- Planning cost reduction due to rising labor costs

_5G・6G電波反射フィルム_png_w500px_h333px.png)

5G/6G Radio Wave Reflective Film

Transparent, thin, and flexible film for efficient diffuse reflection of a wide range of radio waves

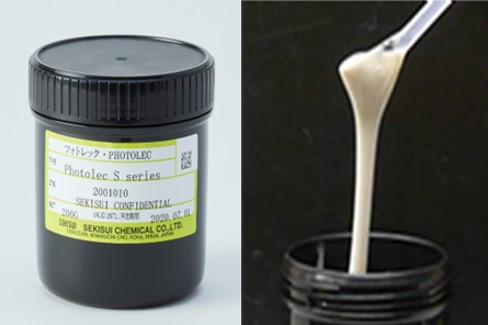

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

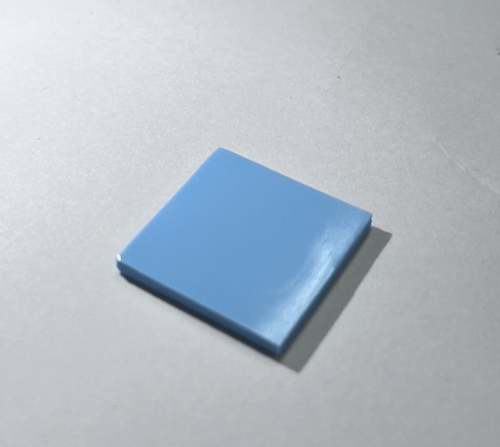

High Thermal Conductivity Heat Dissipation Sheet MANION™ Series

An ultra-high-thermal-conductivity carbon heat dissipation sheet created by magnetic field alignment technology

Thermal Grease CGW™ Series

A two-component high-performance thermal grease that combines flexibility with thermal conductivity

Shorter processes

Curing capability with shorter curing time and high efficiency

We have products capable of responding to your needs such as in the following situations:

- You want a material that has high adhesive strength and can cure even at low temperatures

- You want to increase production efficiency by shortening the curing time of a bonding process

- You want to peel products without damaging the wafers or resin substrates and leaving no adhesive residues

- You want to simplify the existing processes

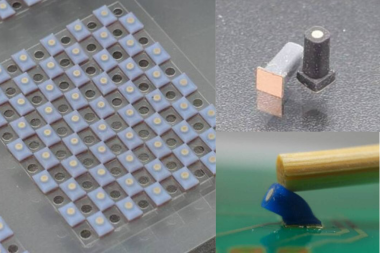

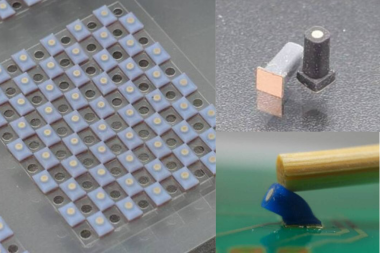

_DOTコネクタ_png_w500px_h333px.png)

Dot Connector

Connector that integrates both conductive and waterproof functions

Dot Connector (SMT,PSA)

Rubber connector with integrated insulating and conductive parts

_防水DOTコネクタ_png_w500px_h333px.png)

Waterproof Dot Connector

Connector that integrates both conductive and waterproof functions

_EPOWELL™CP_png_w500px_h333px.png)

Anisotropic Conductive Paste EPOWELL™CP

Anisotropic conductive adhesive optimized for RFID, enabling low-temperature and short-time mounting

_インクジェット_png_w500px_h333px.png)

Inkjet Ink for Ultra-Fine and High-Aspect-Ration Patterning

High-viscosity inkjet material that enables both freeform patterning and high resolution

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

Low contamination

Stable production processes with no organic contamination and elution of impurities

We have products that enable you to solve such problems as the following:

- Increase in defect rates due to the effect of outgas generated during the heating process

- Particles entering during the semiconductor manufacturing process

- Organic contamination during the panel manufacturing process

- Maintaining quality during the storage of high-purity chemical solutions

- Foreign matter, adhesive residues, etc. during the manufacture of FPCs and PCBs

_熱プレス工程用離型フィルム_png_w500px_h500px.png)

Release Film for Heat Press Process

Multi-layer release film for hot pressing that ensures clean release even under high temperatures

![[フォトマスク用保護フィルム タックウェル™] の製品画像(準備中)](/files/electronics/image/NO IMAGE.png)

Protection Film for Photomasks TACWELL™

Highly durable protection film that prevents release layer peeling

_ソルダーレジストマスキングテープ_png_w500px_h500px.png)

Solder Resist Making Tape

A thin-film masking tape that combines strong adhesion with easy peelability

_クリーン容器_png_w500px_h333px.png)

Clean bottle

High-cleanliness bottle for high-purity chemicals and medical applications

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

For cost reduction

Easy peeling

Reduction of labor costs in the manufacturing process

We have products capable of responding to your needs such as in the following situations:

- You just want to remove the tape and remake products when an abnormality is found in a product inspection

- You want to easily remove the tape after protecting devices in a heating process, such as a reflow process, during the manufacture of various packages

- You want to easily remove the tape after secure bonding or fixing during the grinding process

- You want to disassemble LCD and OLED panels without scratching the panel surface during repair

_易解体・易剥離フォームテープ_png_w500px_h500px.png)

Easy-to-Dismantle/Easy-to-Remove Foam Tape

A reusable flexible foam tape that combines strong holding power with reworkability

_光学フィルム用プロテクトテープ_png_w500px_h500px.png)

Protective Tape for Optical Films 67/68/6900 Series

A high-performance protective tape that minimizes substrate contamination and prevents the beauty of optical films

_研磨布固定用両面テープ_ダブル_png_w500px_h500px.png)

Double-sided Tape for Fixing Polishing Pads

A double-faced tape with a differential design that provides excellent adhesion and easy removability

_防水・衝撃吸収フォームテープ 5200_png_w500px_h500px.png)

Waterproof/Shock-Absorbing Foam Tape 5200 Series

A heat-resistant foam tape that delivers both waterproofing and shock absorption

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

_高遮光高反射両面テープ 3800_png_w500px_h500px.png)

Double-sided adhesive tape 3800 series for fixing LCD components

Double-sided tape for fixing LCD parts

Improved yield rates

Materials free from in-process reworking with less material loss

We have products that enable you to solve such problems as the following:

- Residues from the peeling off of protective tape during the semiconductor manufacturing process

- Followability and embedding properties of protective materials during FPC production

- Damage to printed circuit boards during the removal of process materials due to insufficient release properties

- Wrinkles and cracks on foldable smartphones

_光学フィルム用プロテクトテープ_png_w500px_h500px.png)

Protective Tape for Optical Films 67/68/6900 Series

A high-performance protective tape that minimizes substrate contamination and prevents the beauty of optical films

_UTG向け耐衝撃性高透明樹脂 フォトレック™_png_w500px_h333px.png)

Impact-Resistant and Highly Transparent Resin for UTG Photolec™

Highly durable protection film that prevents release layer peeling

_クリーン容器_png_w500px_h333px.png)

Clean bottle

High-cleanliness bottle for high-purity chemicals and medical applications

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

Reduced waste

Waste reduction in the production process due to the efficient use of materials

We contribute to reducing process waste in the following ways:

- Switching to an adhesive to reduce waste

- Standardizing process materials, such as adhesives and pressure-sensitive adhesives, to cut down on material loss

- Switching to materials with excellent reworkability to reduce the number of various parts

- Changing storage containers to produce less raw material residues

_易解体・易剥離フォームテープ_png_w500px_h500px.png)

Easy-to-Dismantle/Easy-to-Remove Foam Tape

A reusable flexible foam tape that combines strong holding power with reworkability

_UTG向け耐衝撃性高透明樹脂 フォトレック™_png_w500px_h333px.png)

Impact-Resistant and Highly Transparent Resin for UTG Photolec™

Highly durable protection film that prevents release layer peeling

_インクジェット_png_w500px_h333px.png)

Inkjet Ink for Ultra-Fine and High-Aspect-Ration Patterning

High-viscosity inkjet material that enables both freeform patterning and high resolution

_クリーン容器_png_w500px_h333px.png)

Clean bottle

High-cleanliness bottle for high-purity chemicals and medical applications

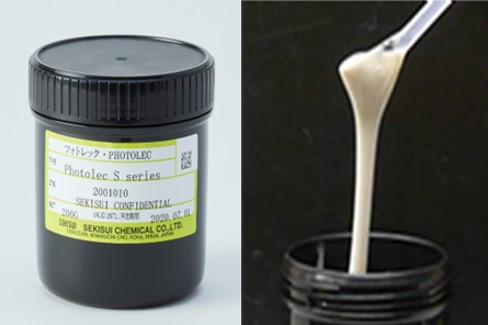

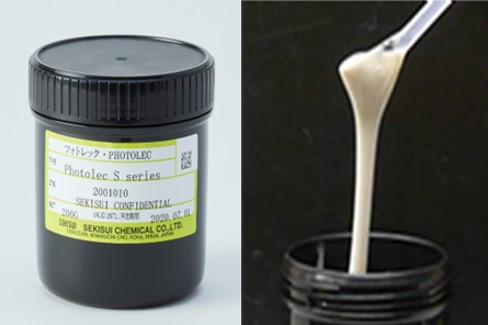

UV + Heat-Curing Low-Contamination Adhesive Photolec™ S

A sealing material ideal for LCD panels, combining narrow-bezel compatibility with non-contaminating properties

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

For improved performance

Durability

Realization of robust quality and long-life design

We offer materials capable of realizing durability in next-generation technologies, including

- Protective materials that improve the final physical properties of cutting-edge foldable smartphones

- PVB capable of simultaneously achieving the three binder properties: toughness, adhesion, and dispersibility

- Low-Df and Low-Dk interlayer insulation materials adaptable to the evolution of semiconductor package substrates

- Heat dissipation materials that improve the durability of final products by achieving flexibility as well as adhesion

- Protective materials that improve the surface condition of solder resist (SR)

_UTG向け耐衝撃性高透明樹脂 フォトレック™_png_w500px_h333px.png)

Impact-Resistant and Highly Transparent Resin for UTG Photolec™

Highly durable protection film that prevents release layer peeling

_DOTコネクタ_png_w500px_h333px.png)

Dot Connector

Connector that integrates both conductive and waterproof functions

Dot Connector (SMT,PSA)

Rubber connector with integrated insulating and conductive parts

_防水DOTコネクタ_png_w500px_h333px.png)

Waterproof Dot Connector

Connector that integrates both conductive and waterproof functions

_ソルダーレジストマスキングテープ_png_w500px_h500px.png)

Solder Resist Making Tape

A thin-film masking tape that combines strong adhesion with easy peelability

_熱硬化型層間絶縁フィルム_png_w500px_h333px.png)

Thermosetting Interlayer Insulating Film

Build-up film that contributes to finer wiring and high-speed communication in electronic devices.

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

High Thermal Conductivity Heat Dissipation Sheet MANION™ Series

An ultra-high-thermal-conductivity carbon heat dissipation sheet created by magnetic field alignment technology

Thermal Grease CGW™ Series

A two-component high-performance thermal grease that combines flexibility with thermal conductivity

Powder Resin for Binder Applications S-LEC™ B,K

A versatile binder resin that combines adhesion, dispersibility, and toughness

Impact resistance

Highly functional products resistant to drops, vibrations, and shocks

We offer impact-resistant materials for such situations as the following:

- Protecting devices, such as digital signage and large TVs, from transportation impact

- Protecting small devices, including smartphones, wearables, and AR and VR devices, from everyday drops and shocks

- Protecting semiconductor package boards, FPCs, optical parts, and other delicate components from shock during manufacturing

_易解体・易剥離フォームテープ_png_w500px_h500px.png)

Easy-to-Dismantle/Easy-to-Remove Foam Tape

A reusable flexible foam tape that combines strong holding power with reworkability

_EXAGEL_png_w500px_h333px.png)

EXAGEL

_Pantel GEL_png_w500px_h333px.png)

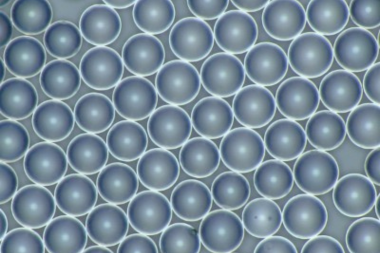

Pantel GEL

Transparent gel material with excellent flexibility and shock absorption

_UTG向け耐衝撃性高透明樹脂 フォトレック™_png_w500px_h333px.png)

Impact-Resistant and Highly Transparent Resin for UTG Photolec™

Highly durable protection film that prevents release layer peeling

_DOTコネクタ_png_w500px_h333px.png)

Dot Connector

Connector that integrates both conductive and waterproof functions

Dot Connector (SMT,PSA)

Rubber connector with integrated insulating and conductive parts

_防水DOTコネクタ_png_w500px_h333px.png)

Waterproof Dot Connector

Connector that integrates both conductive and waterproof functions

_熱硬化型層間絶縁フィルム_png_w500px_h333px.png)

Thermosetting Interlayer Insulating Film

Build-up film that contributes to finer wiring and high-speed communication in electronic devices.

_クリーン容器_png_w500px_h333px.png)

Clean bottle

High-cleanliness bottle for high-purity chemicals and medical applications

_防水・衝撃吸収フォームテープ 5200_png_w500px_h500px.png)

Waterproof/Shock-Absorbing Foam Tape 5200 Series

A heat-resistant foam tape that delivers both waterproofing and shock absorption

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

Heat Dissipation Sheet TIMLIGHT™ Series

A multifunctional heat dissipation sheet that combines flexibility to conform to uneven surfaces and high thermal conductivity

Closed-cell form XLIM™

Next-generation device foam that absorbs impact, even at a thickness of just 0.06 mm

Chemical resistance

Reassuring, highly functional materials that are resistant to oils, acids, and chemicals

We can offer chemical-resistant materials that are the most suitable for your needs, through such properties as

- Withstanding etching, polishing, and chemical treatment processes

- Being suitable for use in mixing with solvents

- Protecting products that people touch on a daily basis, including electronic devices and wearables, from sweat, disinfectants, sunscreen cream, etc

_ミクロパール™_png_w500px_h333px.png)

High-Performance Metal Plated Filler Micropearl™

High-performance functional filler that combines flexibility and conductivity without causing damage

_クリーン容器_png_w500px_h333px.png)

Clean bottle

High-cleanliness bottle for high-purity chemicals and medical applications

_研磨布固定用両面テープ_ダブル_png_w500px_h500px.png)

Double-sided Tape for Fixing Polishing Pads

A double-faced tape with a differential design that provides excellent adhesion and easy removability

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

Plastic-Based High-Performance Filler Micropearl™

High-performance fine particles that meet the needs of next-generation devices with precise thickness control and stress relaxation

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

Heat resistance

Highly reliable materials capable of withstanding reflow processes and long-duration heating

We offer materials that have the thermal durability required to achieve the following:

- Device protection during thermal processes, such as reflow during the production of various packages

- Absence of discoloration in high-heat environments for long periods of time

- mprovement of curing efficiency by making effective use of heat

- Thermal management of areas with high heat generation by using thermal conductivity

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

_EPOWELL™GP_png_w500px_h333px.png)

Adhesive with Precision Gap Control Particles EPOWELL™ GP

High Thermal Conductivity Heat Dissipation Sheet MANION™ Series

An ultra-high-thermal-conductivity carbon heat dissipation sheet created by magnetic field alignment technology

Thermal Grease CGW™ Series

A two-component high-performance thermal grease that combines flexibility with thermal conductivity

Powder Resin for Binder Applications S-LEC™ B,K

A versatile binder resin that combines adhesion, dispersibility, and toughness

For a better environment

CO2 reduction

Highly functional chemical materials that are renewable with low energy consumption

We offer products that contribute to GHG reduction, including

- Bio-based tapes capable of achieving the same performance as that of conventional petroleum-based products

- Kraft tapes that significantly reduce waste volume

- Moisture-curing elastic adhesives that are solvent-free and do not require heating

- Heat dissipation materials that enable heat management without wasting energy

_放熱グリス GAシリーズ_png_w500px_h333px.png)

Silicone-Free Thermal Grease - GA series

A silicon-free thermal grease that enables thin film application and provides low resistance

_熱硬化型層間絶縁フィルム_png_w500px_h333px.png)

Thermosetting Interlayer Insulating Film

Build-up film that contributes to finer wiring and high-speed communication in electronic devices.

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

_環境対応型粘着テープ バイオテープ_png_w500px_h500px.png)

Eco-Friendly Adhesive Tape Bio Tape

A plant-based sustainable tape that maintains high adhesion and strong holding power

High Thermal Conductivity Heat Dissipation Sheet MANION™ Series

An ultra-high-thermal-conductivity carbon heat dissipation sheet created by magnetic field alignment technology

Thermal Grease CGW™ Series

A two-component high-performance thermal grease that combines flexibility with thermal conductivity

Heat Dissipation Sheet TIMLIGHT™ Series

A multifunctional heat dissipation sheet that combines flexibility to conform to uneven surfaces and high thermal conductivity

Reduced waste

Waste reduction in the production process due to the efficient use of materials

We contribute to reducing process waste in the following ways:

- Switching to an adhesive to reduce waste

- Standardizing process materials, such as adhesives and pressure-sensitive adhesives, to cut down on material loss

- Switching to materials with excellent reworkability to reduce the number of various parts

- Changing storage containers to produce less raw material residues

]

_易解体・易剥離フォームテープ_png_w500px_h500px.png)

Easy-to-Dismantle/Easy-to-Remove Foam Tape

A reusable flexible foam tape that combines strong holding power with reworkability

_UTG向け耐衝撃性高透明樹脂 フォトレック™_png_w500px_h333px.png)

Impact-Resistant and Highly Transparent Resin for UTG Photolec™

Highly durable protection film that prevents release layer peeling

_インクジェット_png_w500px_h333px.png)

Inkjet Ink for Ultra-Fine and High-Aspect-Ration Patterning

High-viscosity inkjet material that enables both freeform patterning and high resolution

_クリーン容器_png_w500px_h333px.png)

Clean bottle

High-cleanliness bottle for high-purity chemicals and medical applications

UV + Heat-Curing Low-Contamination Adhesive Photolec™ S

A sealing material ideal for LCD panels, combining narrow-bezel compatibility with non-contaminating properties

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

Low VOC

Products capable of realizing two characteristics: “highly functional chemical products” and “low-hazard substances”

We offer products and services that give consideration to the environment and the human body, such as

- Adhesive products that eliminate health concerns, including odors generated on production lines

- Low-VOC (volatile organic compound) tapes and low-VOC adhesives

- Consultation regarding the use of various chemical materials

_光学フィルム用プロテクトテープ_png_w500px_h500px.png)

Protective Tape for Optical Films 67/68/6900 Series

A high-performance protective tape that minimizes substrate contamination and prevents the beauty of optical films

![[フォトマスク用保護フィルム タックウェル™] の製品画像(準備中)](/files/electronics/image/NO IMAGE.png)

Protection Film for Photomasks TACWELL™

Highly durable protection film that prevents release layer peeling

_ソルダーレジストマスキングテープ_png_w500px_h500px.png)

Solder Resist Making Tape

A thin-film masking tape that combines strong adhesion with easy peelability

_研磨布固定用両面テープ_ダブル_png_w500px_h500px.png)

Double-sided Tape for Fixing Polishing Pads

A double-faced tape with a differential design that provides excellent adhesion and easy removability

_防水・衝撃吸収フォームテープ 5200_png_w500px_h500px.png)

Waterproof/Shock-Absorbing Foam Tape 5200 Series

A heat-resistant foam tape that delivers both waterproofing and shock absorption

UV + Heat-Curing Low-Contamination Adhesive Photolec™ S

A sealing material ideal for LCD panels, combining narrow-bezel compatibility with non-contaminating properties

UV + Moisture-Curing Flexible Adhesive Photolec™ B

A flexible adhesive that follows fine-line patterns and curved surfaces, expanding design flexibility.

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

_高遮光高反射両面テープ 3800_png_w500px_h500px.png)

Double-sided adhesive tape 3800 series for fixing LCD components

Double-sided tape for fixing LCD parts

_導電性粘着テープ 7800シリーズ_png_w500px_h500px.png)

Conductive Adhesive Tape 7800 Series

A strong-adhesion tape for reflow processes that combines high conductivity with heat resistance