Search by Device | Semiconductor- related

Production process flow related to semiconductors

The Electronics Strategy Office is running a wide material portfolio of tape/film/precise particles/sealing material. We are providing high functional products especially for the frontier needs in semiconductor industry, such as Fine L/S, high integrated design, 3D assembly, ultra thin membrane.

Wafer/chip production process

-

-

Protection Tape Lamination

High Adhesion-Easy Removable UV Tape Heat Resistant SELFA™ -

Back Grinding

-

Chemical Plating・High Temperture Treat

High Adhesion-Easy Removable UV Tape Heat Resistant SELFA™ -

Dicing Tape

Lamination -

UV Irradiation・Protection Tape Removing

-

-

Chip Completion

Package substrate production process

-

Copper Core Manufacture

-

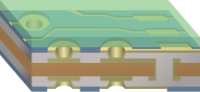

Build Up Film

Build Up Film -

Via, Dismear, Plating,

Masking tape for semiconductor package substrates

Solder Resistant Coating. -

Print DAM material

High-viscosity inkjet ink

Inkjet Material -

Package Substrate Completion

1+2Assembly production process

Tape

_ソルダーレジストマスキングテープ_png_w500px_h500px.png)

Solder Resist Making Tape

A thin-film masking tape that combines strong adhesion with easy peelability

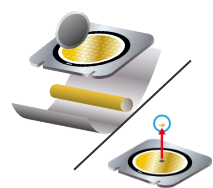

_研磨布固定用両面テープ_ダブル_png_w500px_h500px.png)

Double-sided Tape for Fixing Polishing Pads

A double-faced tape with a differential design that provides excellent adhesion and easy removability

/SELFA.png)

High-Heat-Resistance Temporary Fixing UV Tape SELFA™ Series

A high-heat-resistance, high-adhesion temporary fixing tape enabling easy removal through UV irradiation

Sheet

Film

Adhesive

Microsphere・Filler

_ミクロパール™_png_w500px_h333px.png)

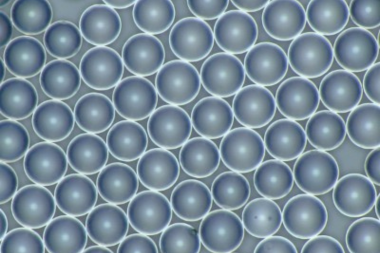

High-Performance Metal Plated Filler Micropearl™

High-performance functional filler that combines flexibility and conductivity without causing damage

Plastic-Based High-Performance Filler Micropearl™

High-performance fine particles that meet the needs of next-generation devices with precise thickness control and stress relaxation

_熱硬化型層間絶縁フィルム_png_w500px_h333px.png)

_インクジェット_png_w500px_h333px.png)

_クリーン容器_png_w500px_h333px.png)