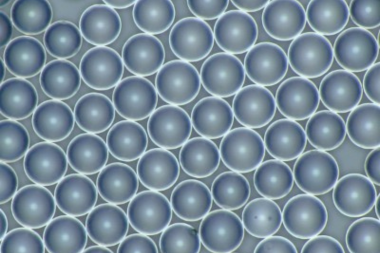

Plastic particles with uniform particle size distribution

2025-09-30

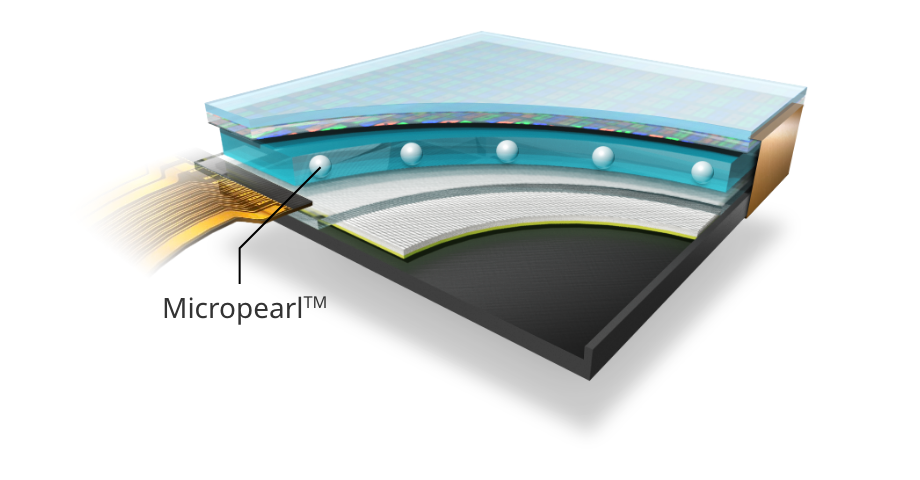

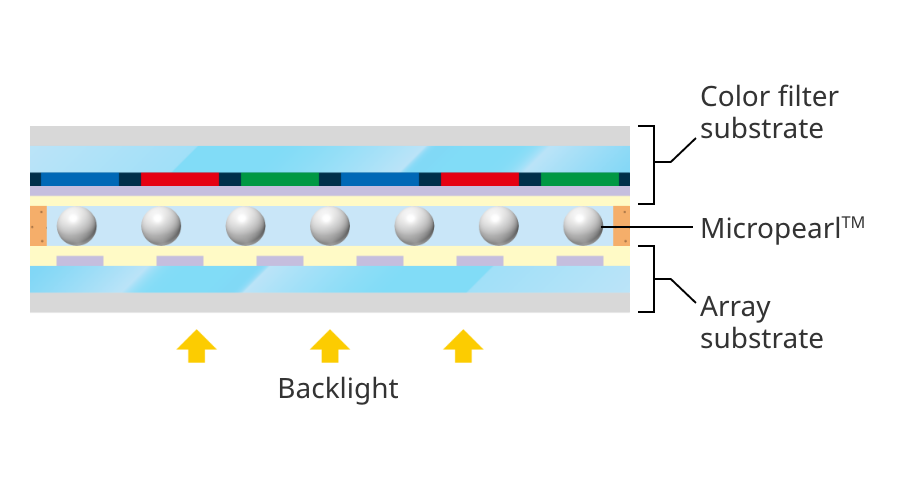

Thickness control of display panel

Challenge

There are many liquid crystal displays (LCD) around us, and they support our convenient modern lives. In an LCD, clear and highly-responsive display is enabled by controlling the molecule orientation of the liquid crystal layer located between two glass substrates. For the liquid crystal layer, a precise gap control on the order of several μm is required, and therefore it is necessary to maintain a uniform height even when a small amount of pressure is applied to any portion within the surface.

SEKISUI's Solution

- Once Micropearl™ SP is dispersed in the liquid crystal layer, it functions as a high-accuracy spacer by taking advantage of its uniform particle size distribution.

- As Micropearl™ has a resin composition with flexibility, it reduces damage to the substrate and surrounding part/material even when a strong pressure is applied to it.

- Various particle sizes and hardness/resilience control allow us to offer products that suit customers’ demands.

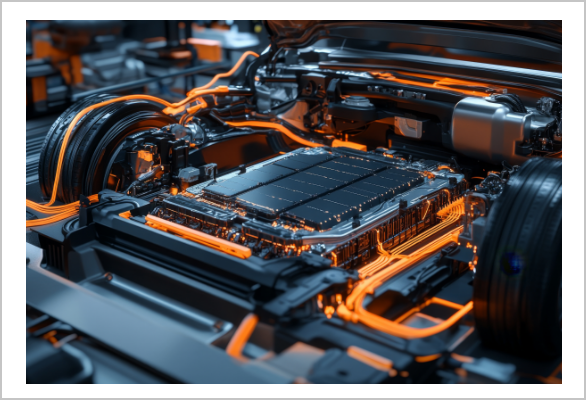

Relaxation of stress to solid electrolyte layer of all-solid-state battery

Challenge

Toward realization of a carbon neutral society, the demands for storage battery in BEV (Battery Electric Vehicle), PHEV (Plug-in Hybrid Electric Vehicle), and others are increasing, and all-solid-state battery is anticipated to become a safe and high-performance next-generation battery.

The challenges in the development of all-solid-state battery include generation of internal stress in association with the expansion and contraction of anode/cathode and performance degradation due to defective contact between solid electrolytes associated with the internal stress.

SEKISUI's Solution

- Addition of Micropearl™ SP as stress relaxing agent is anticipated to reduce damage to part/material as it absorbs stress at the time of expansion and to maintain the contact between electrolytes at the time of contraction.

- Adding Micropearl™ to between collectors or between cells is anticipated to reduce damage to the surrounding part/material.

- Micropearl™ can also function as a spacer by taking advantage of its uniform particle size.

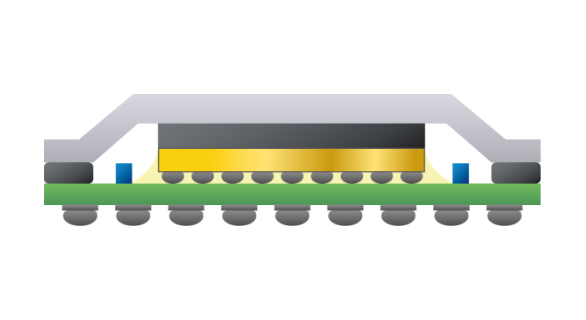

Formation of uniform gap between semiconductor element and substrate

Challenge

A power semiconductor is a device that has become necessary for equipping sensors/cameras on vehicle as the vehicle performance has been enhanced.

In mounting of semiconductor chip on a substrate, advanced film thickness control of adhesion layer typified by solder paste and silver paste plays an important role. However, it is difficult to manufacture a film at an arbitrary and uniform film thickness.

SEKISUI's Solution

- By kneading paste with Micropearl™ in advance, the adhesion layer exhibits a spacer function at the time of semiconductor mounting, and pressurized mounting achieves the same film thickness as the spacer size.

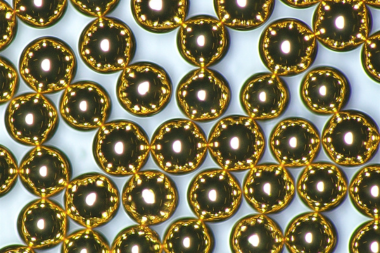

- Plastic-based Micropearl™, which exhibits better particle size uniformity, more flexibility, and lower specific gravity compared to glass beads, contributes to excellent handleability and improvement of product performance.

- It is also possible to plate the surface of Micropearl™ with metal of a high solderability.Please seeherefor details.

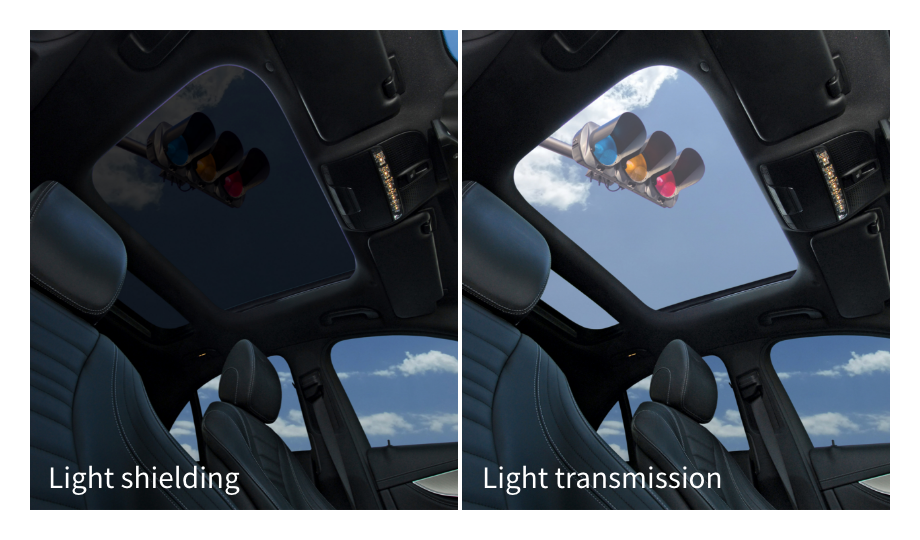

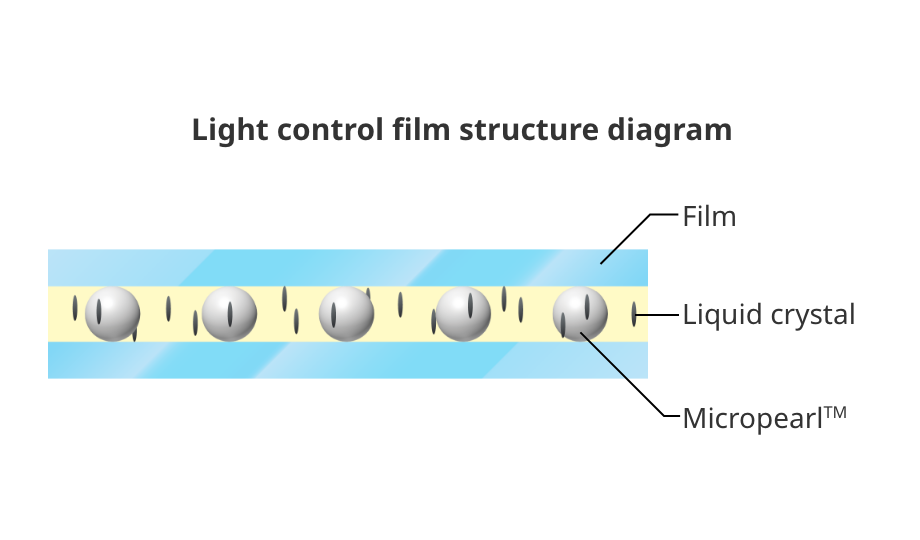

Glass light control

Challenge

In response to the needs for securing privacy and reducing in-vehicle temperature rise, and due to the convenience of its instant ON/OFF switching capability, light control film glass has been increasingly employed as vehicle exterior glass.

For light control film/glass, many properties including contrast, responsiveness, curved surface followability, and durability are required.

SEKISUI's Solution

- Due to its uniform particle size distribution and less large-size particles, Micropearl™ allows uniform gap control.

- With high flexibility and springiness, Micropearl™ prevents damage to substrate and particle movement.

- Excellent in voltage resistance, heat resistance, and chemical resistance, Micropearl™ contributes to retention of high reliability even in a high-temperature high-humidity environment.