- Mobility

- Electronics

- Sustainability

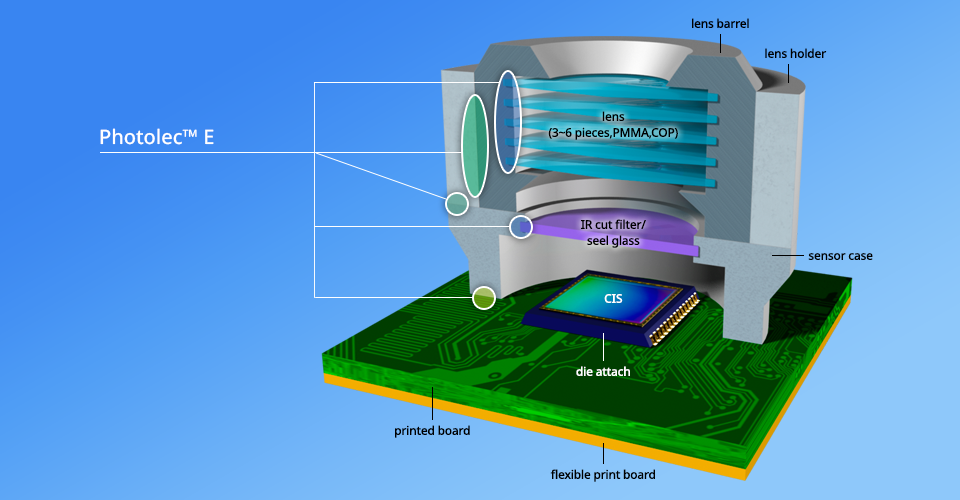

UV and Low-Temperature Curing, Low-Moisture Permeable Adhesive Photolec™ E

A low-moisture-permeability UV-curable adhesive that bonds light-shielding substrates at low temperatures in a short time.

- Mobility

- Electronics

- For processes where UV irradiation is not possible

- Delayed curing adhesive for UV-impermeable materials

- Technical information

- Document download

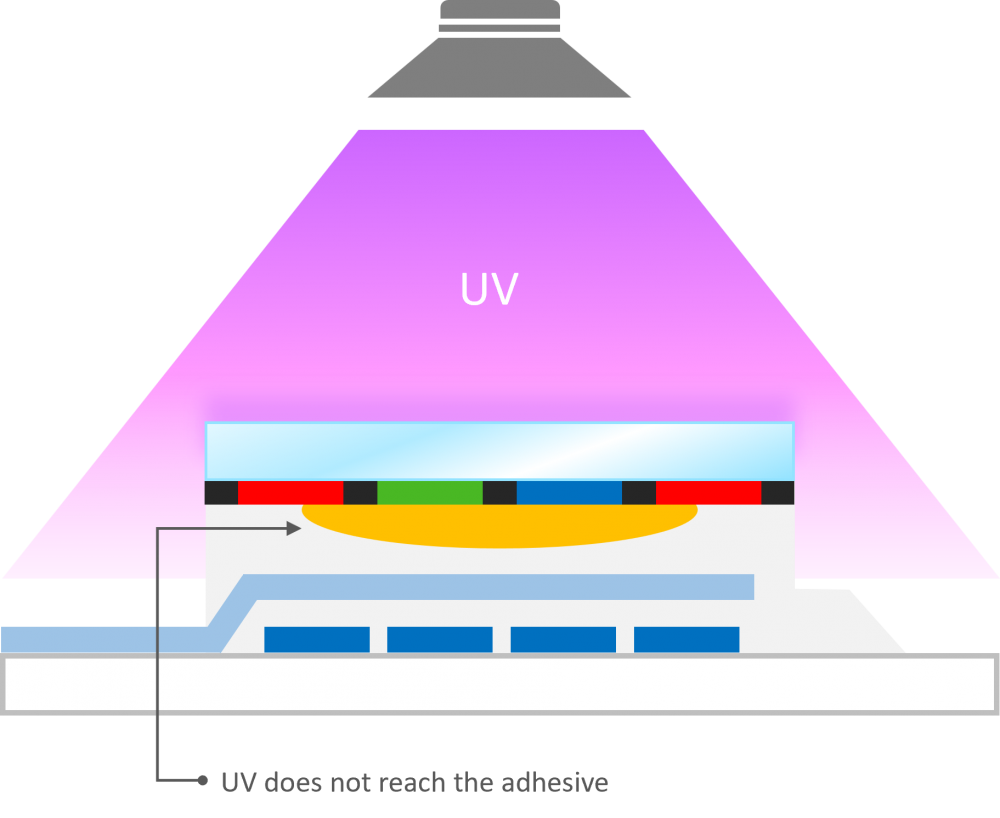

For processes where UV irradiation is not possible

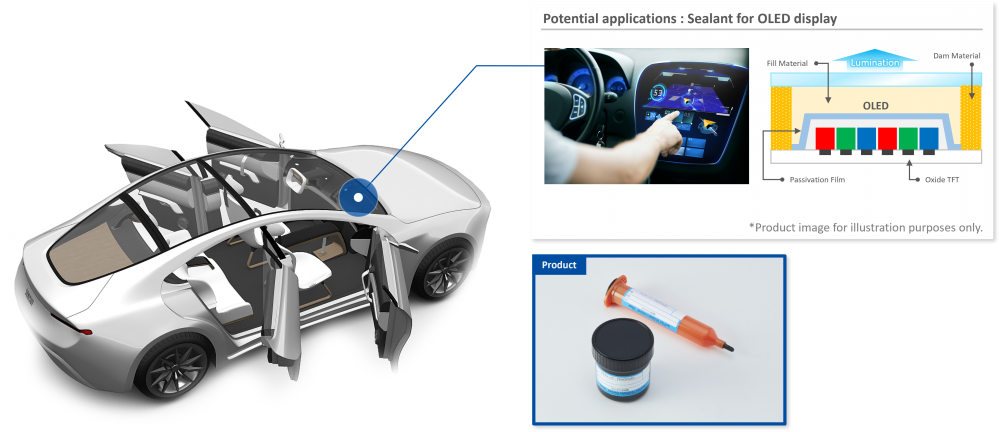

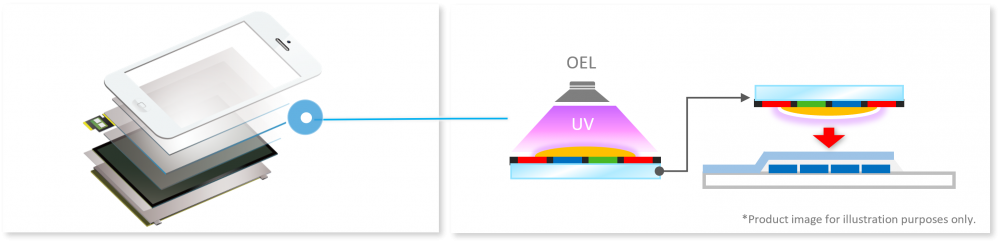

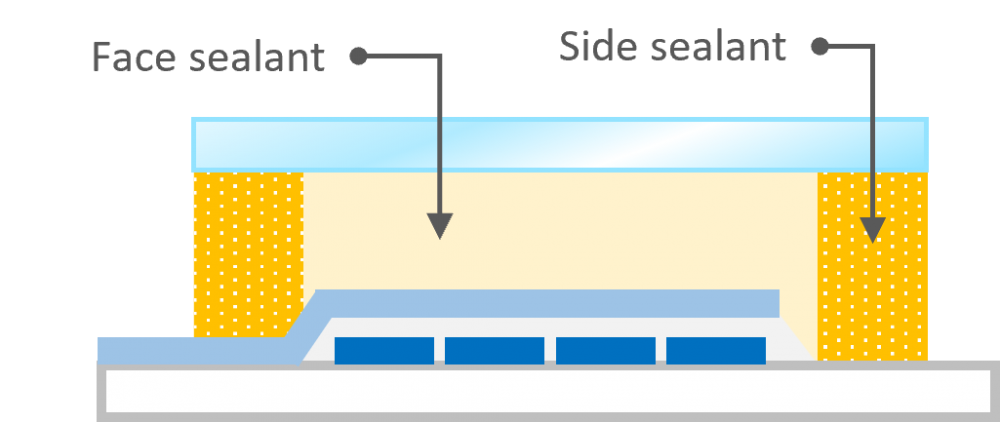

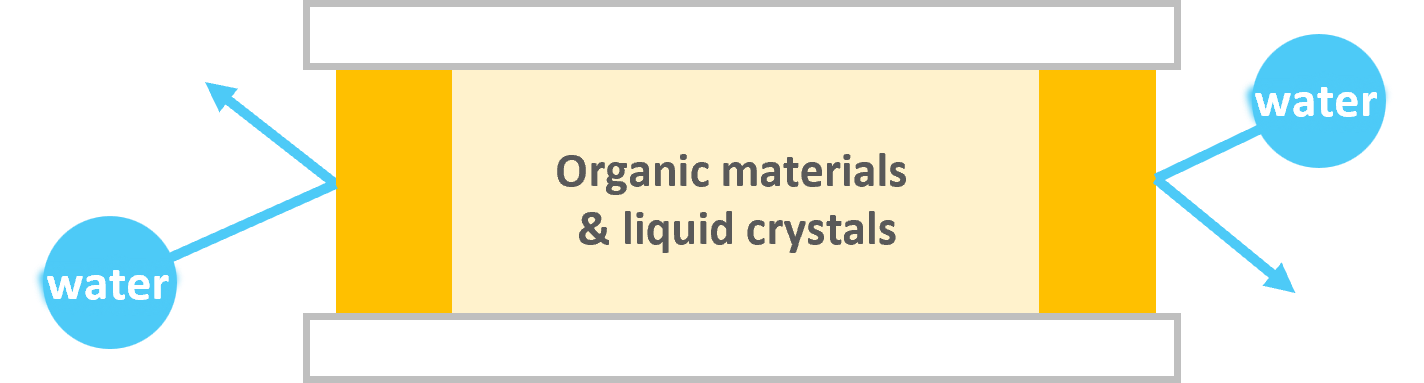

In the processes of attaching camera modules, which are key components of in-vehicle cameras used in advanced driver assistance systems (ADAS), and organic light-emitting diode (OLED) displays used in center information displays (CIDs), some processes do not allow UV irradiation due to UV-impermeable or UV-sensitive materials being used in the surfaces.

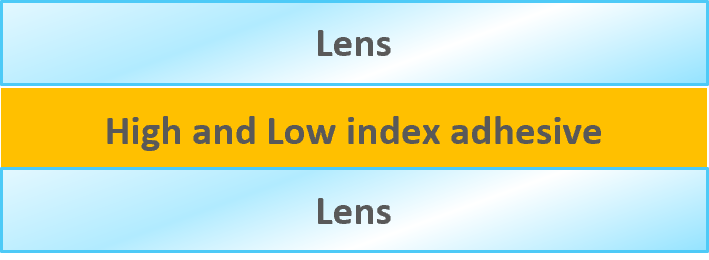

Furthermore, water penetration from the bonding area, which can cause defects in these components, must be prevented, and especially for OLED panels, high-optical performance is required.

Delayed curing adhesive for UV-impermeable materials

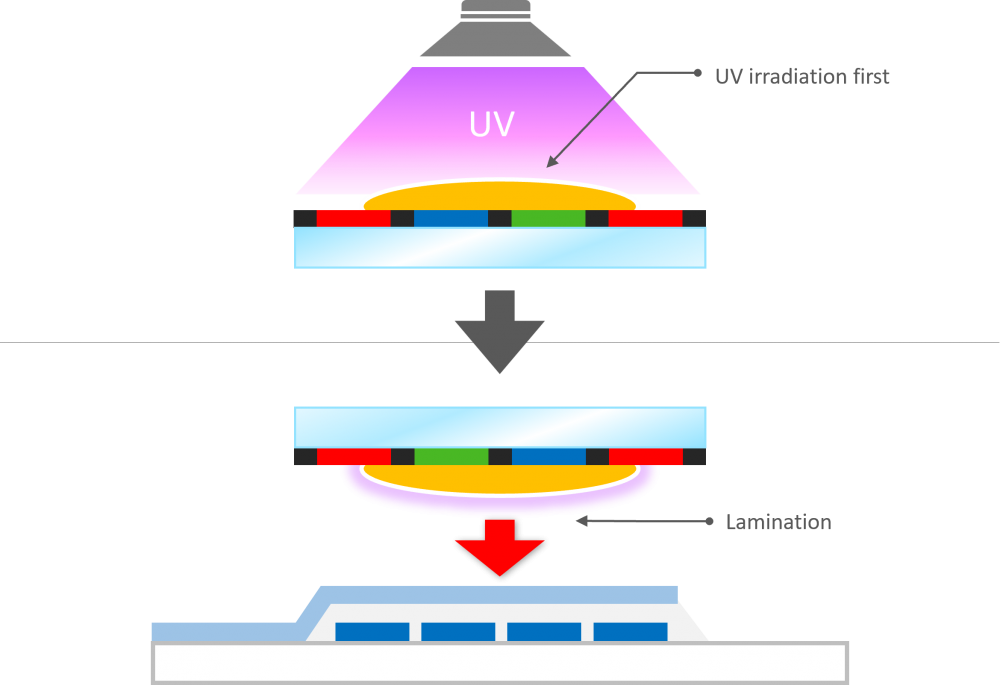

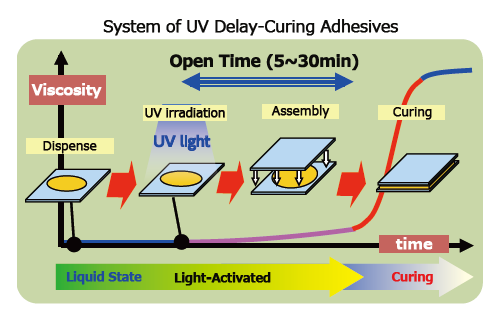

The UV delayed curing low-moisture-permeable adhesive, Photolec E, is a UV delayed curing adhesive that can be applied to UV-impermeable materials and UV-sensitive surfaces.

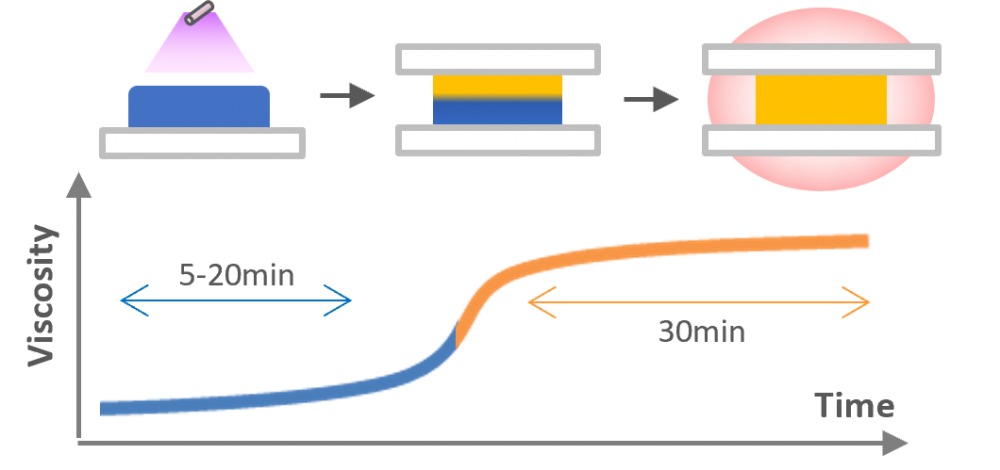

With its delayed curing (adjustable from 5 to 20minutes) instead of curing immediately after UV irradiation, Photolec E can be used for processes that cannot be performed with immediate curing by UV irradiation.

Low-moisture permeability, contamination-resistant resin prevents contamination or water penetration from external factors.

With a wide range of product lineups, it is capable of offering a variety of solutions to meet the needs of each application.

Technical information

Technical overview

UV post-curing

UV post-curing

Adhesion adjustment

After UV irradiation5-20 minutes adjustable.

Low pollution

Low pollution

Pollution and moisture resistance

prevent contamination and pollution LC,organic materials.

Optical properties

Optical properties

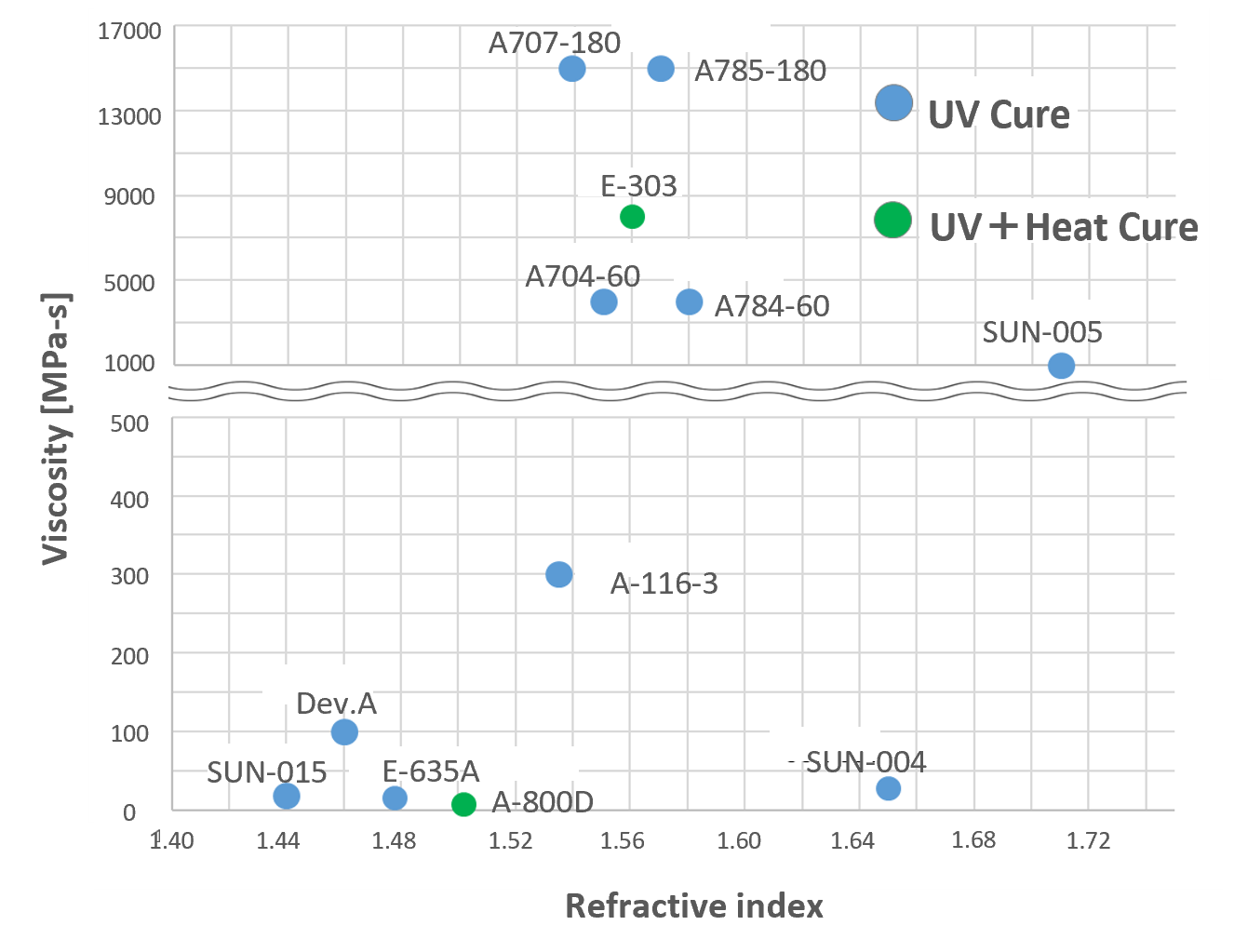

Refractive index adjustment

Adjustable from 1.44 to 1.71.

Wide product lines

Wide product lines

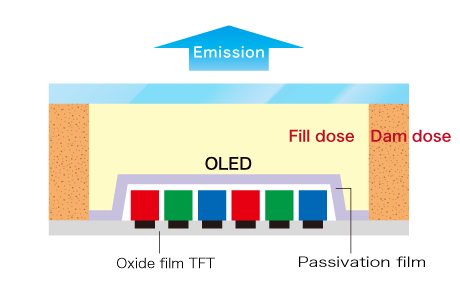

Dam and fill materials

proposals can be madeaccording to the application.

Technical details

UV post-curing

UV post-curing

Low pollution

Low pollution

Prevents contamination of each material by preventing moisture from entering

Optical properties

Optical properties

Wide product lines

Wide product lines

| Standard | High moisture resistance |

Low temperature cure |

|||

|---|---|---|---|---|---|

| E305 | E220 | E303 | |||

| Viscosity | 25℃/5rpm | MPa・s | 250 | 290,000 | 7,000 |

| Ti | 1rpm/10rpm | 1.0 | 2.1 | 1.0 | |

| WVTR | 60℃90% 300μm |

g/m2-24h | 22 | 6 | 33 |

| Storage conditions | 10°C or less | ||||

| Use conditions | Normal temperature | ||||

Characteristics

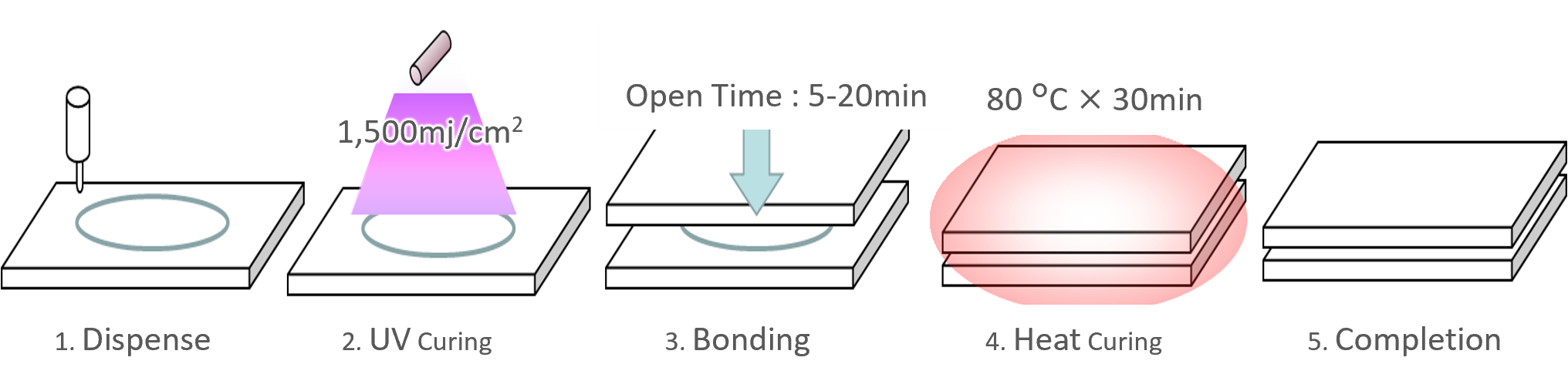

- Curing will start a few minutes after UV irradiation. By heating at low temperature for a short time, it cures quickly.

- Low Outgas, Moisture-proof

Temporary curing procees

Dispense→UV Curing→Bonding→Heat Curing

Applications

1After-cure

This type is best for sealing materials which are subject to heat, for polarizing parts, and for plastic plates.

2Low moisture permeability

Moisture-proof sealant for OLED Display

- This product releases minimal gas generated during curing proccess (UV/heat)

- Semiconductor (MEMS, CCD) sealing

Low Outgas

Strong and highly accurate adhesion can be achieved

※ With Plastic-based Micropearl™

- Bonding for plastic substrates

- Bonding for optical components

- Hard disks, surrounding sealants (low moisture permeability), internal adhesive (low outgas)

- Semiconductor(MEMS,CCD camera module)

Document download

- All

- Electronics

- Mobility