- Electronics

- Sustainability

Plastic-Based High-Performance Filler Micropearl™

High-performance fine particles that meet the needs of next-generation devices with precise thickness control and stress relaxation

High-performance fine particles produced with proprietary particle manufacturing technology, combining precise particle size distribution with excellent dispersibility and flexibility. They contribute to thickness control and stress relaxation in applications such as spacers for light control films and glass, as well as in fields including displays,semiconductor packaging, and all-solid-state batteries.

- Electronics

- Hardness & lineup

- Comparison Table

- Micropearl™ SP,GS,EX

- Micropearl™ KB,KY

- Micropearl™ EXH

- Micropearl™ EZ,SLC

- Document download

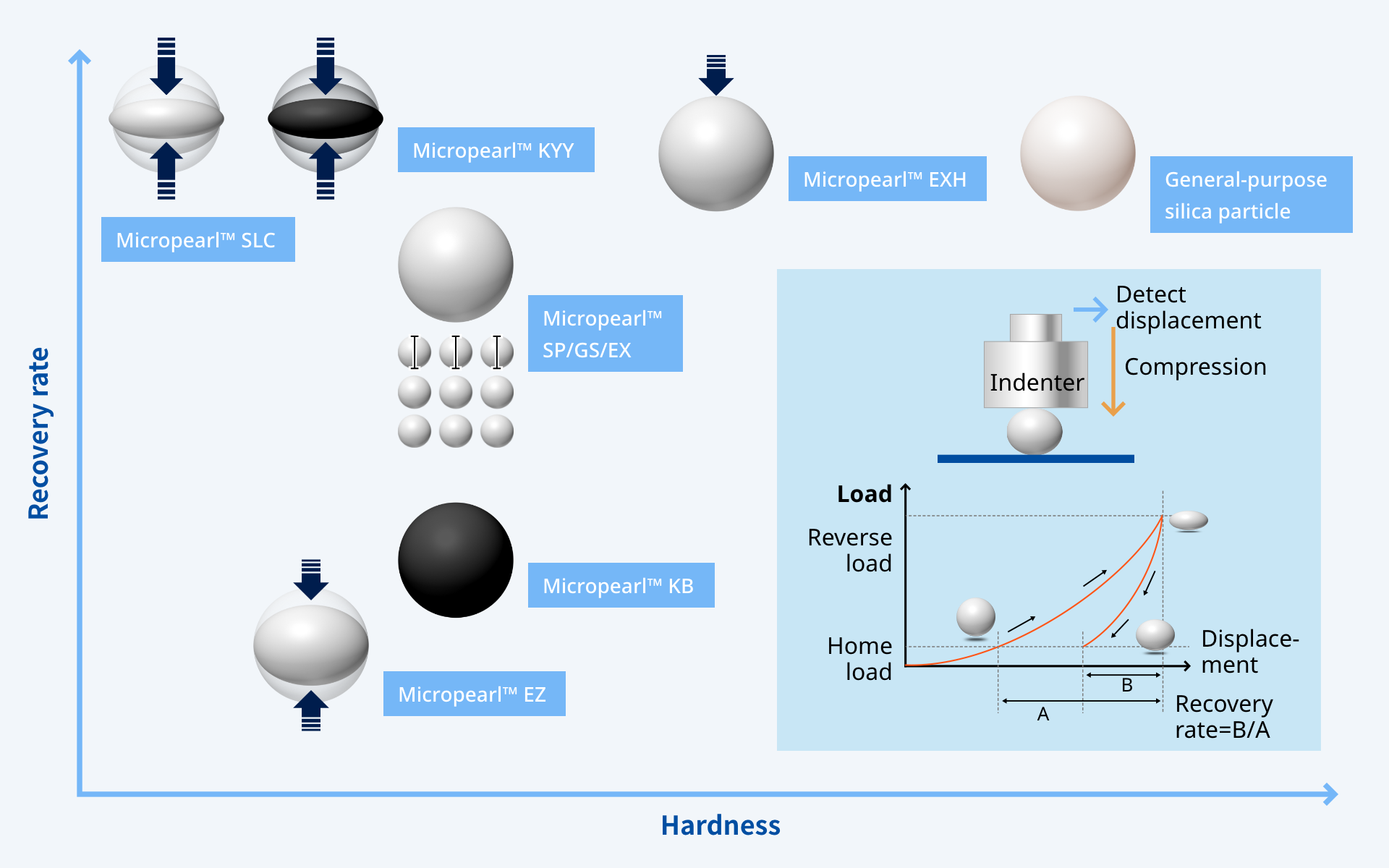

Hardness/particle size lineup

Micropearl™

Product- SP

- GS

- EX

overview

-

- SP

- GS

- Plastic particles with uniform particle size distribution

- Capable of uniform thickness control

- Voltage resistance, heat resistance, and chemical resistance

-

- EX

- Plastic particles with more uniform particle size distribution

→Capable of highly precise thickness control. - Excellent voltage resistance, heat resistance, and chemical resistance

Micropearl™

Product- KB

- KY

overview

-

- KB

- Polymer particles dispersed with carbon black

- Excellent blackness, light shielding effect, resistance to exudation, heat resistance, and chemical resistance

→Usable in wide range of applications.

-

- KY

- Polymer particles dispersed with black “insulated” pigment

→Usable at parts subject to voltage when there is a risk of short-circuiting.

Micropearl™

Product- EXH

overview

-

- Polymer particles with high hardness

→Excellent dimension stability against pressurization - Low specific gravity compared to glass beads

→ Prevention of sedimentation in resin

- Polymer particles with high hardness

Micropearl™

Product- EZ

- SLC

overview

-

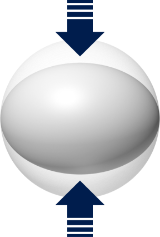

- EZ

- Polymer particles with flexibility

→Effective for reducing vibration noise and of damage to substrate - Low recovery rate

→Also optimum as gap material for soft base material such as film.

-

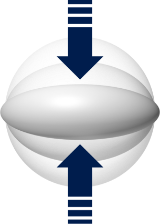

- SLC

- Silicone-based particles

- Capable of reducing vibration noise, reducing cure shrinkage, and soft base material thickness control.

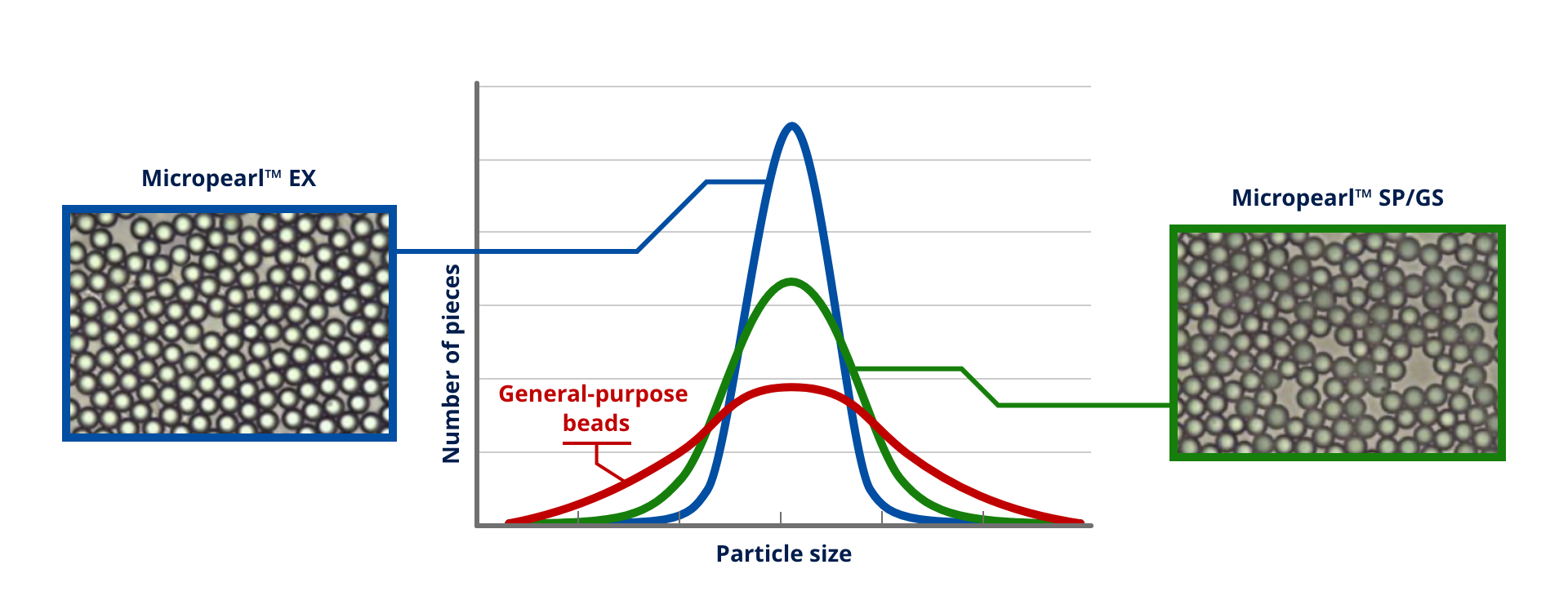

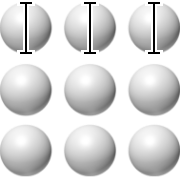

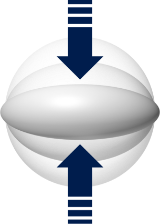

Comparison in hardness and particle size

We offer hard to soft products with particle sizes ranging from1.5 µm to 600 µm in accordance with applications.

Hardness

Particle size

Particle size

| Particle size | Cv | |

|---|---|---|

| Micropearl™ EX |

|

2〜3% |

| Micropearl™ SP |

|

5% |

| Micropearl™ GS |

|

7% |

Micropearl™ SP,GS,EX

Micropearl™ SP,GS,EX

Characteristics

- Small particle size

- Gap control

- Provision of embossing

- Simulated specimen

- Process saving

- Heat resistance

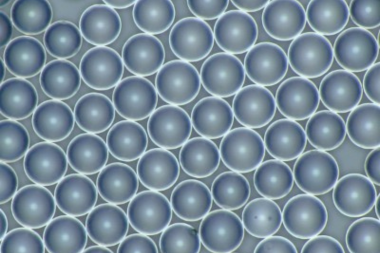

Plastic particles with uniform particle size distribution capable of uniform thickness control. Excellent in voltage resistance, heat resistance, and chemical resistance.

Advantages of using plastic particles

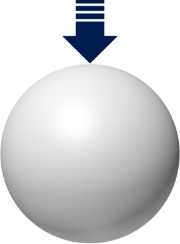

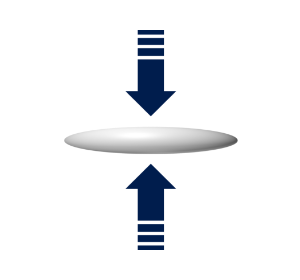

1Hardness control

Offering optimum hardness, not too hard nor too soft.

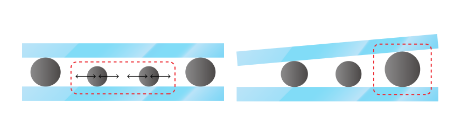

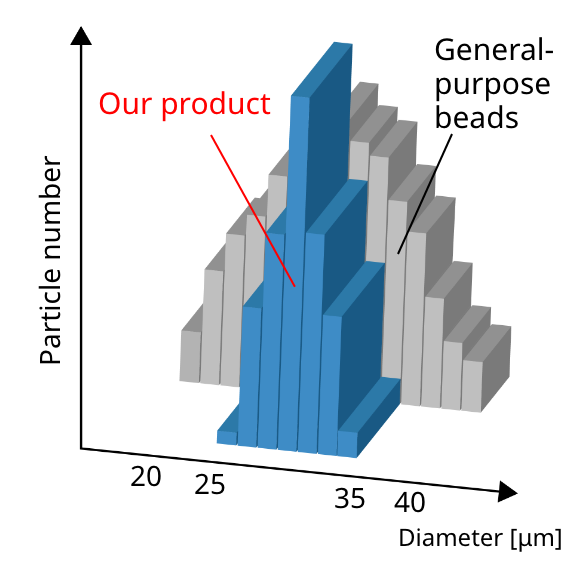

2Excellent particle size distribution

In pursuit of higher definition and higher precision at low Cv value.

| Micropearl™ EX | General purpose beads | |

|---|---|---|

| Cv | Low Cv (narrow particle size distribution) | High Cv (wide particle size distribution) |

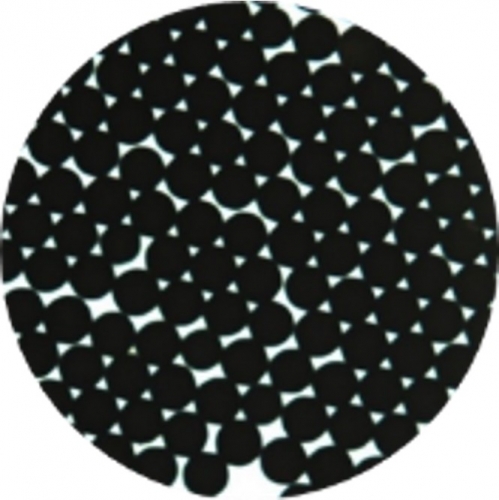

| Image diagram |  |

|

| On vibration | Inhibit the movement of particles | Easy movement of particles |

| Number of particles | Higher number of particles engaged in gap control. Effective gap control with fewer particles. |

Fewer particles are engaged in gap control Higher number of particles required for gap control. |

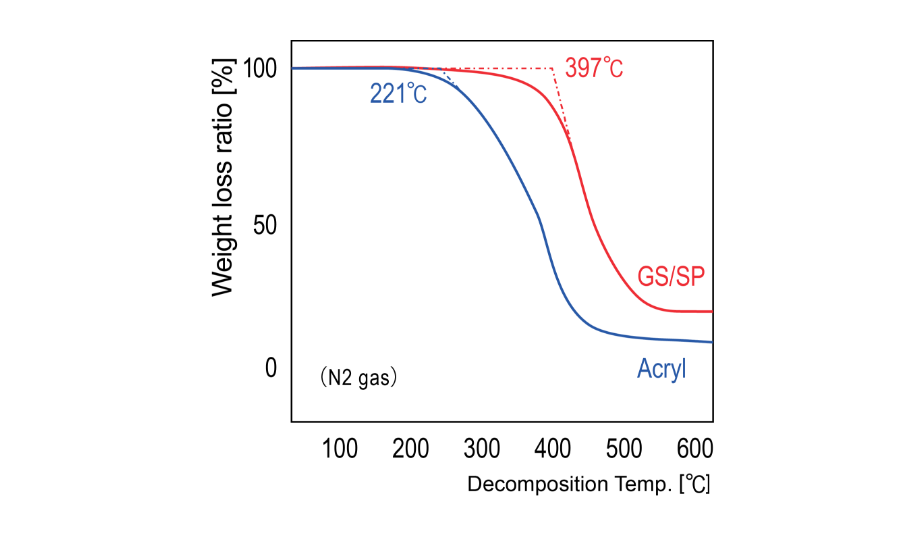

3Stability

Due to its excellent heat resistance compared to acryl particles, Micropearl™ is stable even in the temperature range of −40 to 200°C.

Applications

It is possible to provide a comb of particles and adhesives.

- LCD spacer (display/light control)

- Gap control for adhesive (Sensor/Enclosure/Other electric and optical components)

- Embossing molding material

- Simulated/inspection specimen

- Coloring agent containing particles

Micropearl™ KB,KY

Micropearl™ KB,KY

Characteristics

- Small to large particle sizes

- Gap control

- Provision of embossing

- Simulated specimen

- Process saving

- Light shielding effect

- Heat resistance

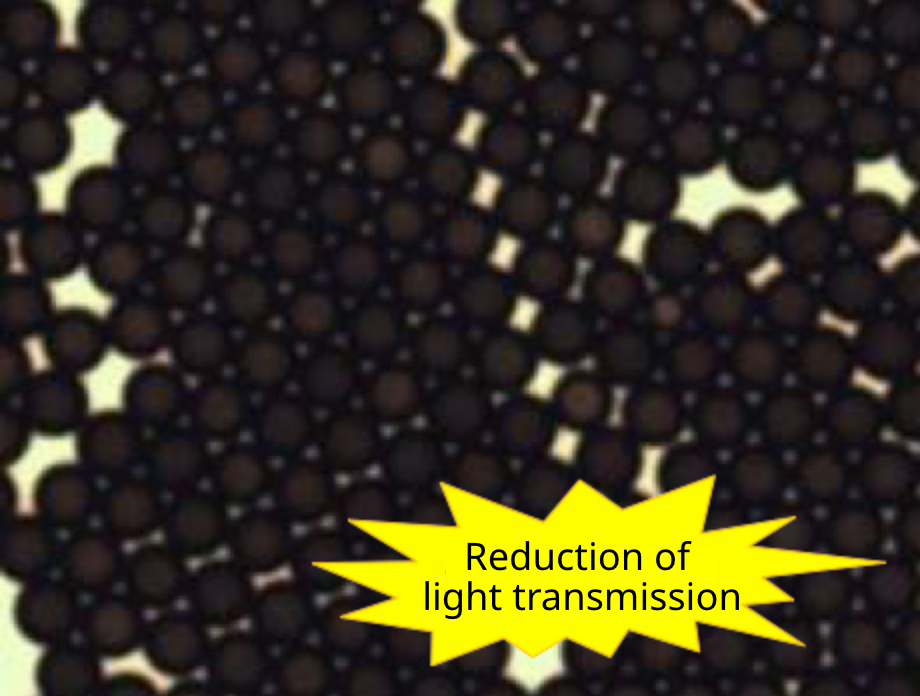

Polymer particles with black pigment dispersed, exhibiting excellent blackness, light shielding properties, and resistance to exudation and corrosion.

Excellent heat and chemical resistant products can be used in wider range of applications.

Advantages of using plastic particles containing black pigment

Applications

Please consider this model when Micropearl™ is required to have a light shielding effect.

- Display related applications

- Optical lens related products

- Simulated/inspection specimen

- Smart (light control) glass

Micropearl™ EXH

Micropearl™ EXH

Characteristics

- Hard

- Small to medium particle size

- Gap control

- Provision of embossing

- Process saving

- Heat resistance

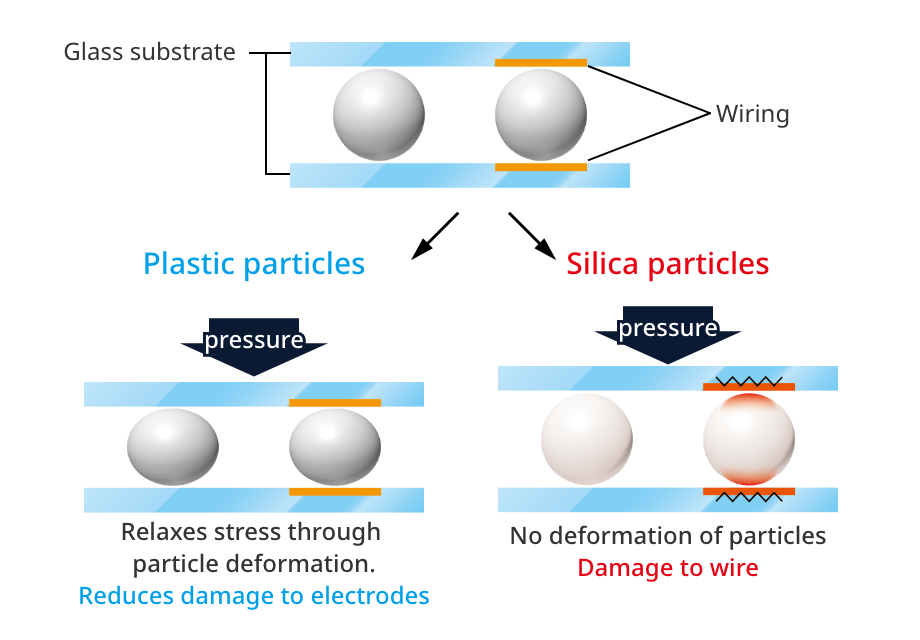

Even though it is a polymer particle, it has excellent dimensional stability against pressurization due to its high hardness. Compared to inorganic particles, it also reduces damage to the substrate and prevents sedimentation in resin.

Advantages of using high-hardness plastic particles

Applications

- Substitution of Silica particles

- Can be added to adhesives for gap material.

- Gap material between glass substrates

Micropearl™ EZ,SLC

Micropearl™ EZ,SLC

Characteristics

- Soft

- Gap control

- Reduction of cure shrinkage

- Small to ultra large particle size

- Heat resistance

- Reduction of damage

- Hole forming

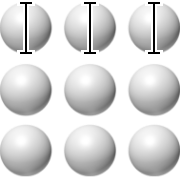

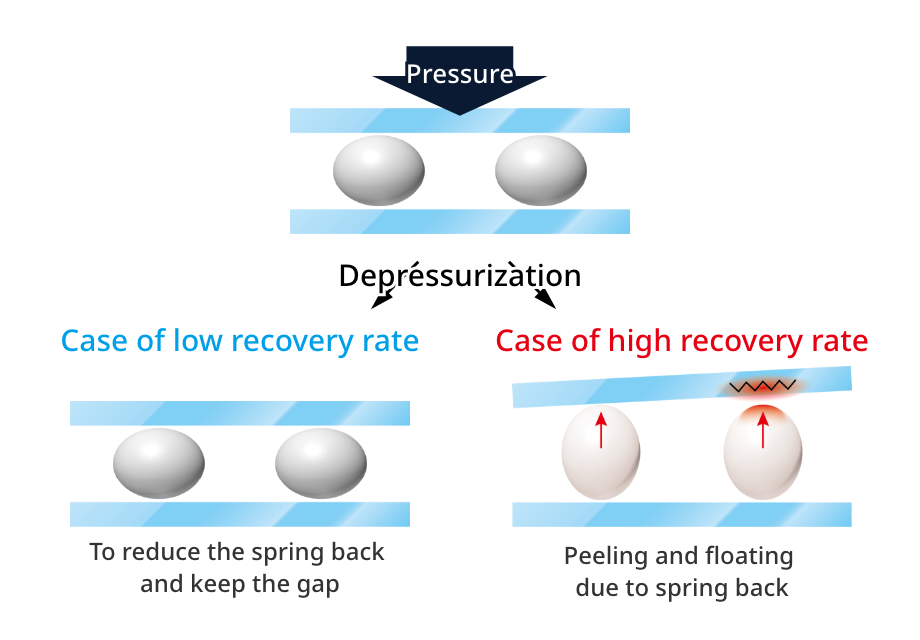

The model EZ, soft polymer particles, exhibits excellent vibration noise reduction and substrate damage reduction effects. Due to its low recovery rate, the model EZ is also optimum for gap control of soft base materials including film.

The model SLC, soft silicone-based particles, exhibits excellent vibration noise reduction and substrate damage reduction effects. This model exhibits heat resistance unique to silicone, and is chemically stable.

SLCAdvantage of using soft particles

As this model deforms in accordance with the pressure applied, damage caused at the time of mounting can be reduced.

EZAdvantage of using soft particles with low recovery rate

- It is possible to minimize damage to the substrate, wiring, and others.

- It is possible to absorb vibration noise from the surrounding area.

- It is anticipated to reduce spring back, prevent adhesive layer peeling, and improve reliability.

EZApplications

- Adhesive for (pressure) sensor

- Conductive paste/die bonding agent

- Adhesive to be applied between films

SLCApplications

- Gap material for silicone adhesive

- Gap material for conductive paste/die bonding agent

Document download

- All

- Electronics

| Name | Type | File | Update | File |

|---|---|---|---|---|

| Catalog 〈Electronics〉:Plastic-Based High-Performance Filler Micropearl™ | Electronics | 2025-09-30 | Download384.89 KB |