What is a “Booth-less” painting?

~Contributing to CO2 Reduction through Painting Technology~

Automobiles are painted with coatings that enhance the exterior design, protect against deterioration and corrosion caused by environmental factors and weather fluctuations, and safeguard against wear and tear to maintain long-term durability. Painting techniques play a major role in maintaining the beautiful appearance of a vehicle’s paint for a long period of time without peeling or discoloration.

What is a painting booth?

In the automotive industry, a painting booth is a specialized area where cars are meticulously painted to perfection. The car body painting process typically involves four key stages: Pre-Treatment, Electrodeposition, Intermediate Coating, and Top Coating. Achieving a perfect finish is paramount, which means zero tolerance for dust and dirt in each stage. The painting booth prevents dust and other substances from entering, while also regulating environmental conditions such as temperature and humidity. Additionally, it features an exhaust function to ensure consistent quality control.

What is a “booth-less” painting?

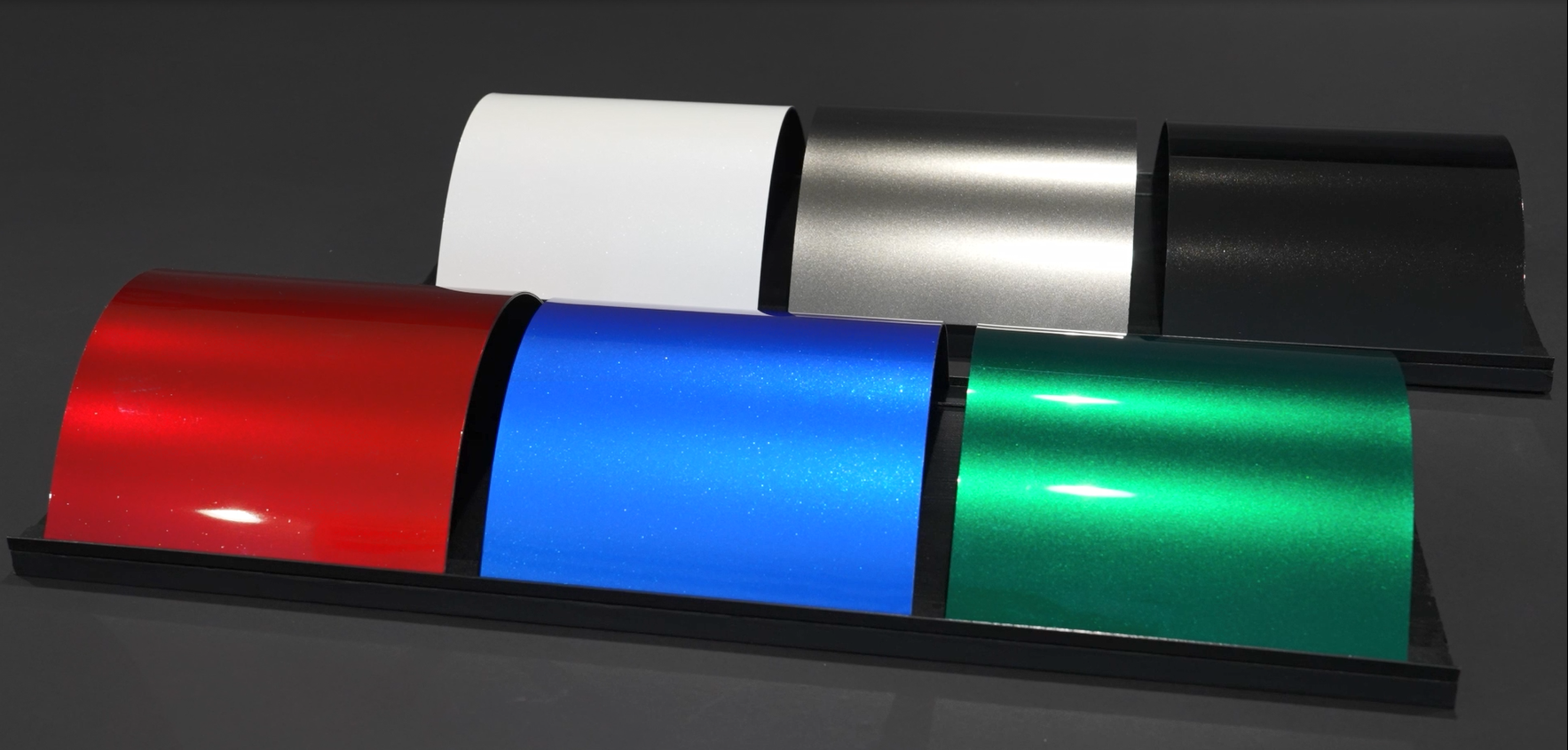

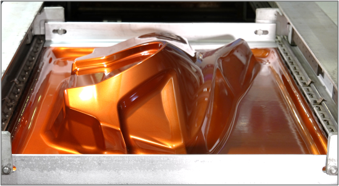

The “Booth-less” painting method is a painting technique that requires no booths. It refers to a spray-free painting technique that eliminates the need for a temperature- or humidity-controlled space for spray painting or equipment to collect spray mist with water. The technology transfers the paint to the car body via a film rather than spraying it. It not only minimizes painting space requirements, but it also contributes to environmental sustainability by decreasing CO2 emissions as well as water usage.

Frequently Asked Questions (FAQ)

- Q:Does it meet the exterior specifications of the vehicle?

- A:Yes, it generally does.

- Q:Yes, it generally does.

- A:It is 140℃ for 18 minutes. We are also developing a low-drying type.

- Q:What are the target materials?

- A:Adhesion to electrodeposition coating, topcoat paintings, ABS, and glass has been confirmed.

- Q:Can it apply to complex shapes?

- A:The paint is uncured, allowing it to mold to complex shapes through the thermoforming.

- Q:Can it be repaired?

- A:Traditional methods such as polishing touch-up, and spray re-coating are applicable.