_光学フィルム用プロテクトテープ_png_w500px_h500px.png)

Protective Tape for Optical Films 67/68/6900 Series

A high-performance protective tape that minimizes substrate contamination and prevents the beauty of optical films

- Electronics

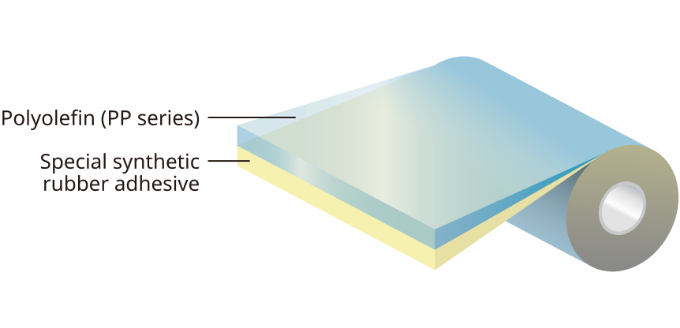

Structure & Features

- Strong adhesion: Sticks well even to bumpy surfaces to provide protection

- Co-extrusion method: Eco-friendly production method that uses a solvent-free manufacturing process

- No adhesive residue: Peels off easily without contaminating the adherend

- Clean environment: Simple method that keeps contaminants out

Features

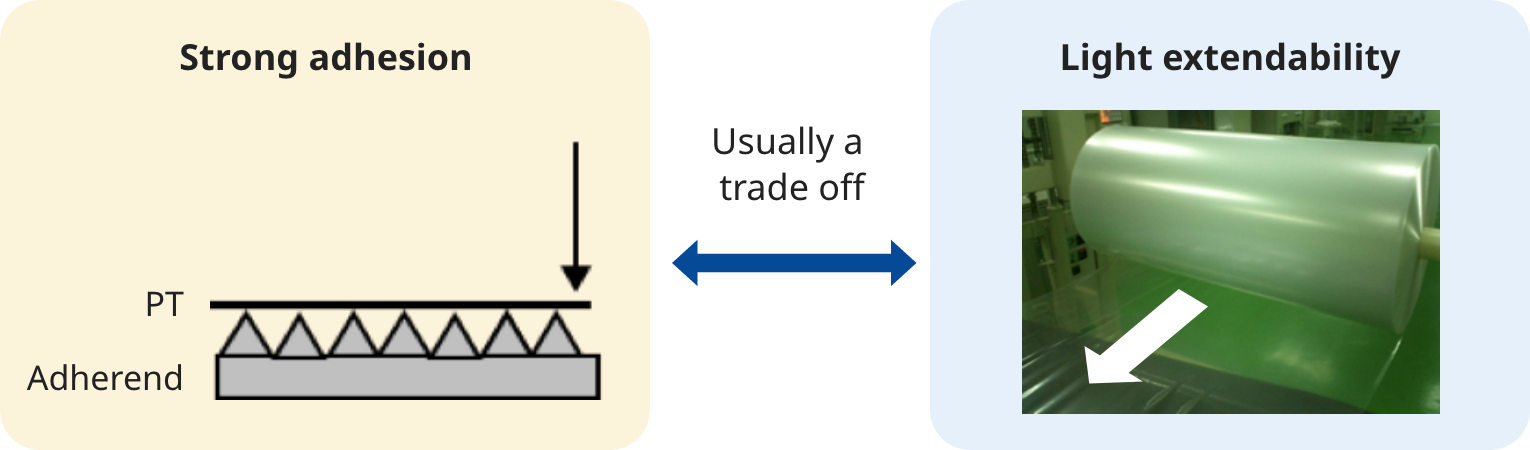

1Strong adhesion and light extendability

SEKISUI products maintain light extendability even with strong adhesion.

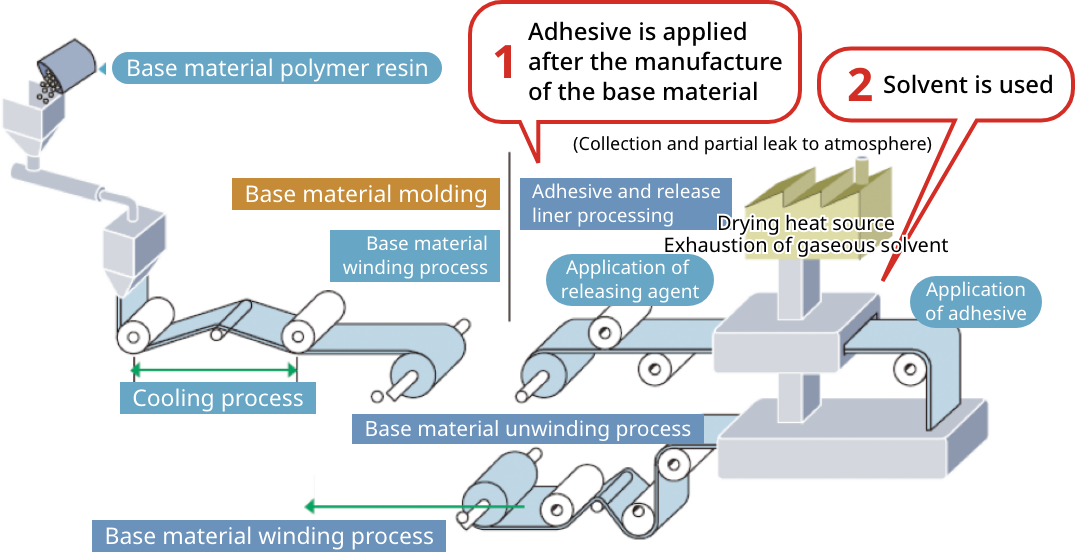

2Eco-friendly dual-layer co-extruded production process with no adhesive residue

- Conventional production process

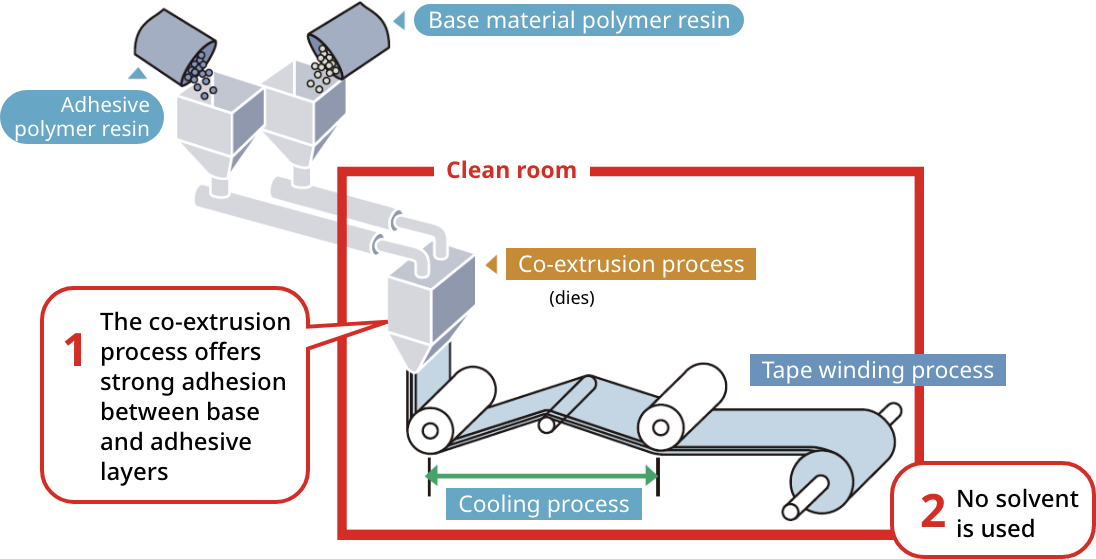

- SEKISUI’s dual layer co-extrusion production process

The solvent-free production process is kind to the environment.

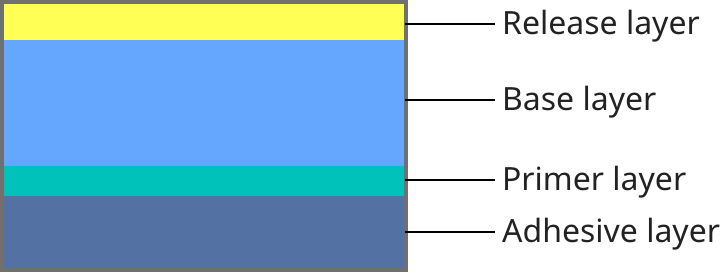

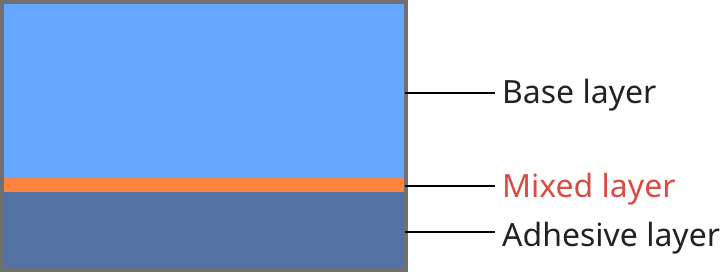

Tape construction that enables SEKISUI’s production process

- Competitor’s coated product

- SEKISUI co-extruded product

Strong bonding between the base and adhesive layers means almost no adhesive residue is left on the surface of an adherend.

3Clean production minimizes FE and other contaminants

SEKISUI’s protective tape is produced in a class 10,000 clean room environment.

Production in an environment from which microparticles and dust have been eliminated as much as possible minimizes the risk of dirt or scratches on the optical film surface.

Class 10,000: No more than 10,000 airborne microparticles (0.5 μm or larger) in a 1 ft3(30 cm square) space

Images are only illustrative.

SEKISUI’s clean rooms achieve a clean environment that has only 1/300 the number of microparticles as a regular plant.

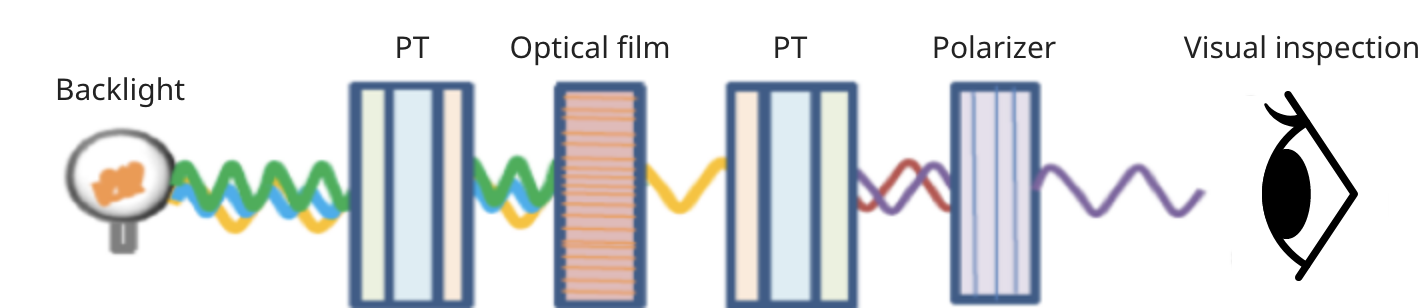

4Adjustment of phase retardation to meet requirements

| Re | 67.5 | 81 | 90 | 101 | 112.5 | 124 | 135 |

|---|---|---|---|---|---|---|---|

| Polarization color |  |

|

|

|

|

|

|

Adjusting the phase retardation simplifies visual inspection and helps streamline work.

Product Lineup

Strong adhesion type (PP film)

General physical properties: 6700 series

| Grade | 6748C | 6754A | 672NZ | 675KA | ||

|---|---|---|---|---|---|---|

| Color | Transparent | Transparent | Transparent | Transparent | ||

| Standard thickness | μm | 40 | 30 | 40 | 40 | |

| Haze | % | 40 | 50 | 15 | 50 | |

| Elasticity modulus (MD) | Mpa | 700 | 700 | 900 | 700 | |

| Tensile strength (MD) | N/cm | 20 | 20 | 23 | 20 | |

| Tensile elongation (MD) | % | 600 | 600 | 700 | 600 | |

| Adhesion (23℃,PMMA plate) |

180°peel | N/25mm | 6 | 5 | 5 | 6.5 |

| Applications | Prism surface of brightness enhancement film | |||||

- The above figures are only measurements; their values are not guaranteed.

General physical properties: 6800, 6900 series

| Grade | 6844B | 6842C | 6942A | ||

|---|---|---|---|---|---|

| Color | Transparent | Transparent | Transparent | ||

| Standard thickness | μm | 40 | 75 | 40 | |

| Haze | % | 40 | 40 | 40 | |

| Elasticity modulus (MD) | Mpa | 700 | 700 | 700 | |

| Tensile strength (MD) | N/cm | 20 | 30 | 20 | |

| Tensile elongation (MD) | % | 600 | 600 | 600 | |

| Adhesion (23℃,PMMA plate) |

90°peel | N/25mm | 0.7 | 0.3 | 0.3 |

| Applications | Matte surface of brightness enhancement film | ||||

- The above figures are only measurements; their values are not guaranteed.

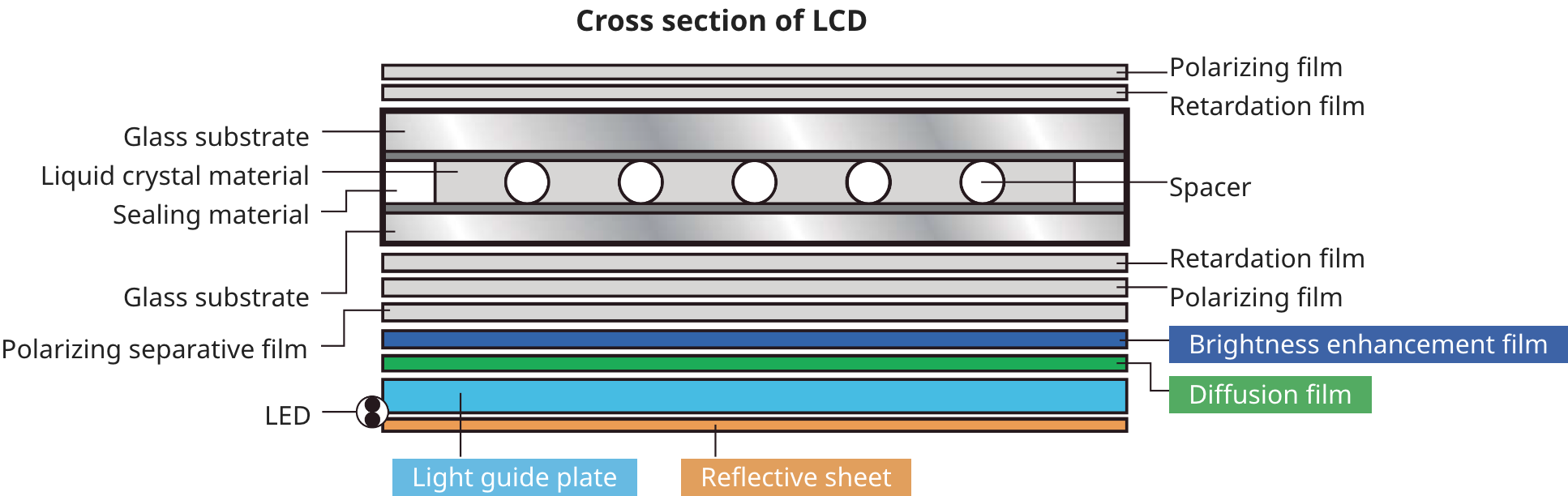

Applications

Protecting the surfaces of optical films (e.g., diffusion film, brightness enhancement film, light guide plate, reflective sheet)

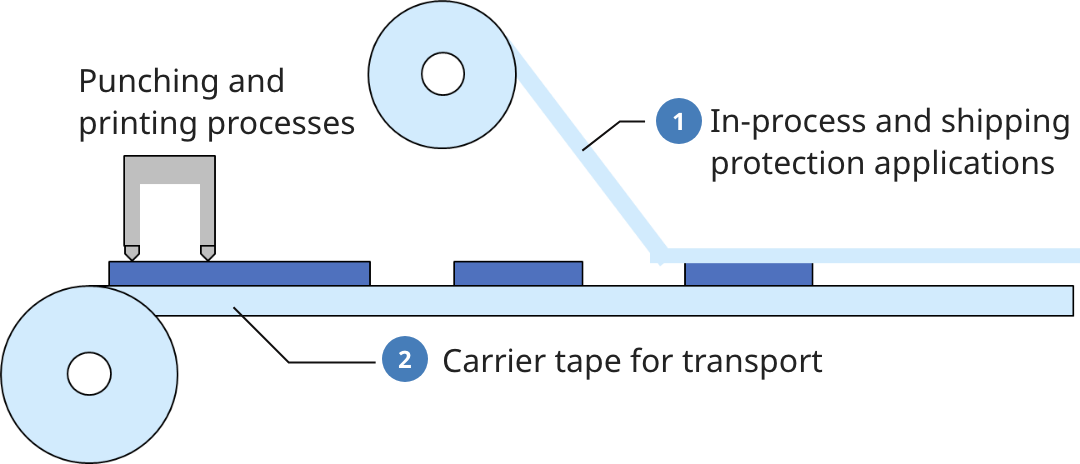

In-process and shipping protection applications / carrier tape for transport

- In-process and shipping protection applications

- →Prevents scratches and contamination

- Carrier tape for transport

- Mounting paper for punching

- Backing for thin-film products

- For transport during processes in processing

Are you experiencing these issues? Our sales and technical support team will help you

- Adhesion residue remains on your products / product damage

- You are having problems with adhesion strength / You want a different tape thickness