_易解体・易剥離フォームテープ_png_w500px_h500px.png)

Easy-to-Dismantle/Easy-to-Remove Foam Tape

A reusable flexible foam tape that combines strong holding power with reworkability

- Electronics

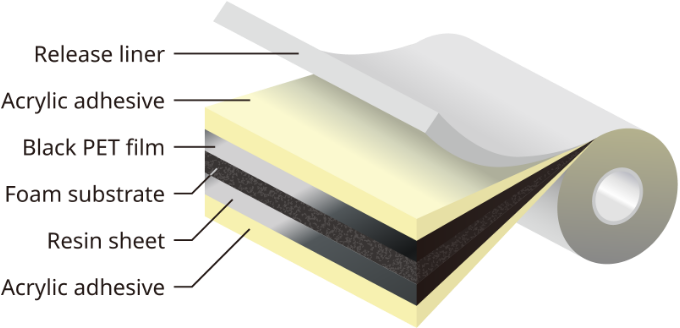

Structure & Features

- Easy-to-Remove properties that enables manual removal of the tape from bonded objects

- Holding performance on tilted surfaces that can withstand static heavy loads

- Flexible foam absorbs repulsion to conform to curved surfaces without lifting or peeling

Features

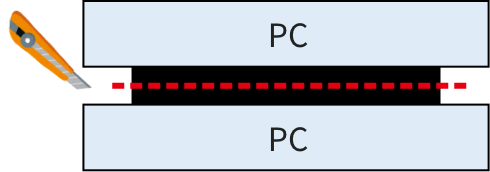

1Very easy to dismantle

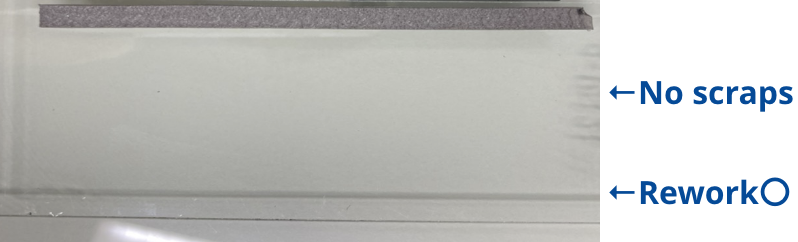

Evaluation method

Two PC panels are stuck together with a 5 mm wide piece of tape, and the tape is removed after the form layer splits and disintegrates.

Results

| Tape | Scraps from cutting | Rework | Photo of sample | ||

|---|---|---|---|---|---|

| Results | Reason | Results | Reason | ||

| SEKISUI’s PE product | (none) |

Strong foam base with a closed-cell structure | (No tape remains) |

Strong reworked layer |  |

| Competitor A’s PU product | (Scraps produced) |

Weak foam base with an open-cell structure | (No tape remains) |

Strong reworked layer |  |

| Competitor B’s PU product | (Scraps produced) |

Weak foam base with an open-cell structure | (Tape remains) |

Weak reworked layer |  |

SEKISUI products possess excellent processability, reworkability, and workability properties.

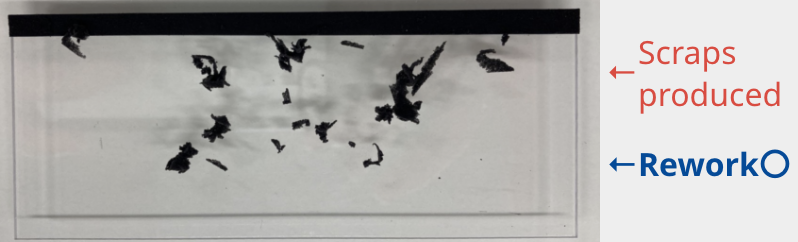

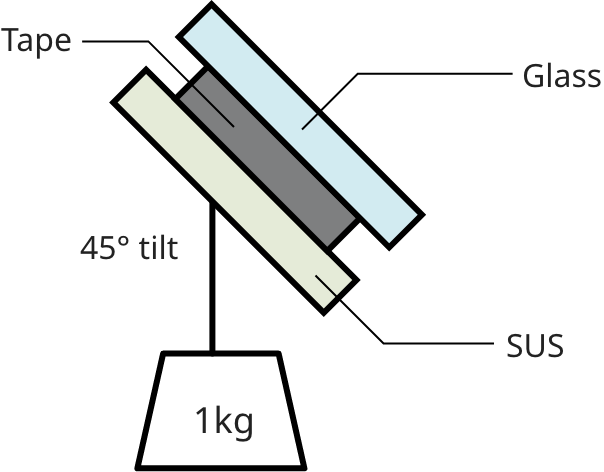

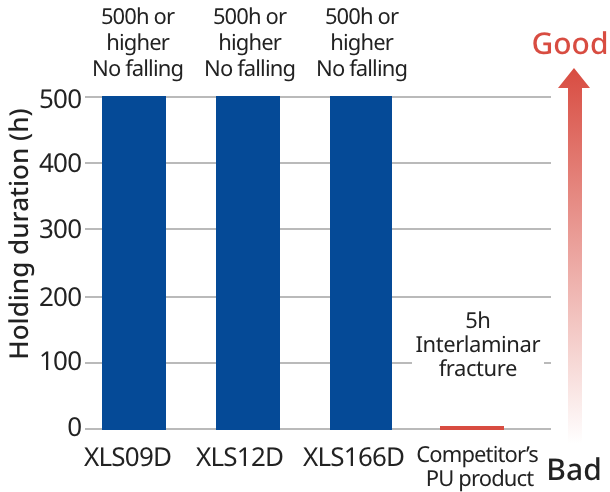

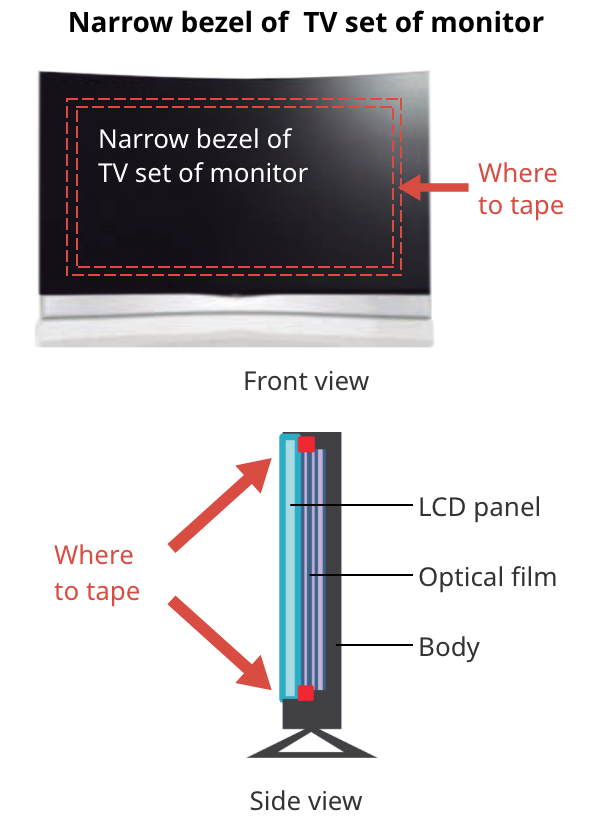

2Strong holding performance on tilted surfaces

Simulated situation for evaluation

This evaluation is based on the assumption that the flexible foam tape was used to install a TV set obliquely.

Evaluation method

- Stick glass or SUS objects together with a clamp over the tape.

- Hang a 1 kg weight from it and measure how long it takes to fall.

| Measurement temperature | 60°C 90%RH |

|---|---|

| Tape size | 25mm × 25mm |

| Pressure application conditions | 5kg*10sec |

| Curing conditions | 23°C 50%RH*24hr |

| Tilt angle | 45° |

| Test duration | Up to 500h |

Results

SEKISUI’s super strong base materials keep adherends from falling even in tilt retention tests.

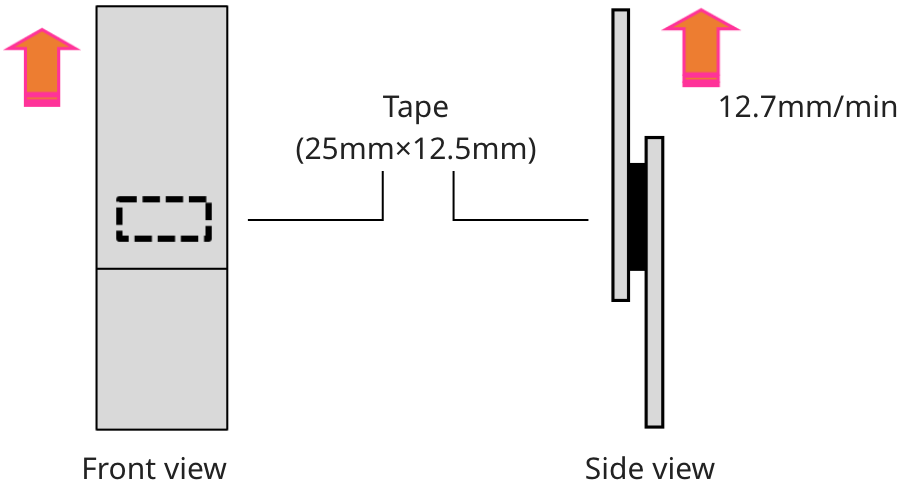

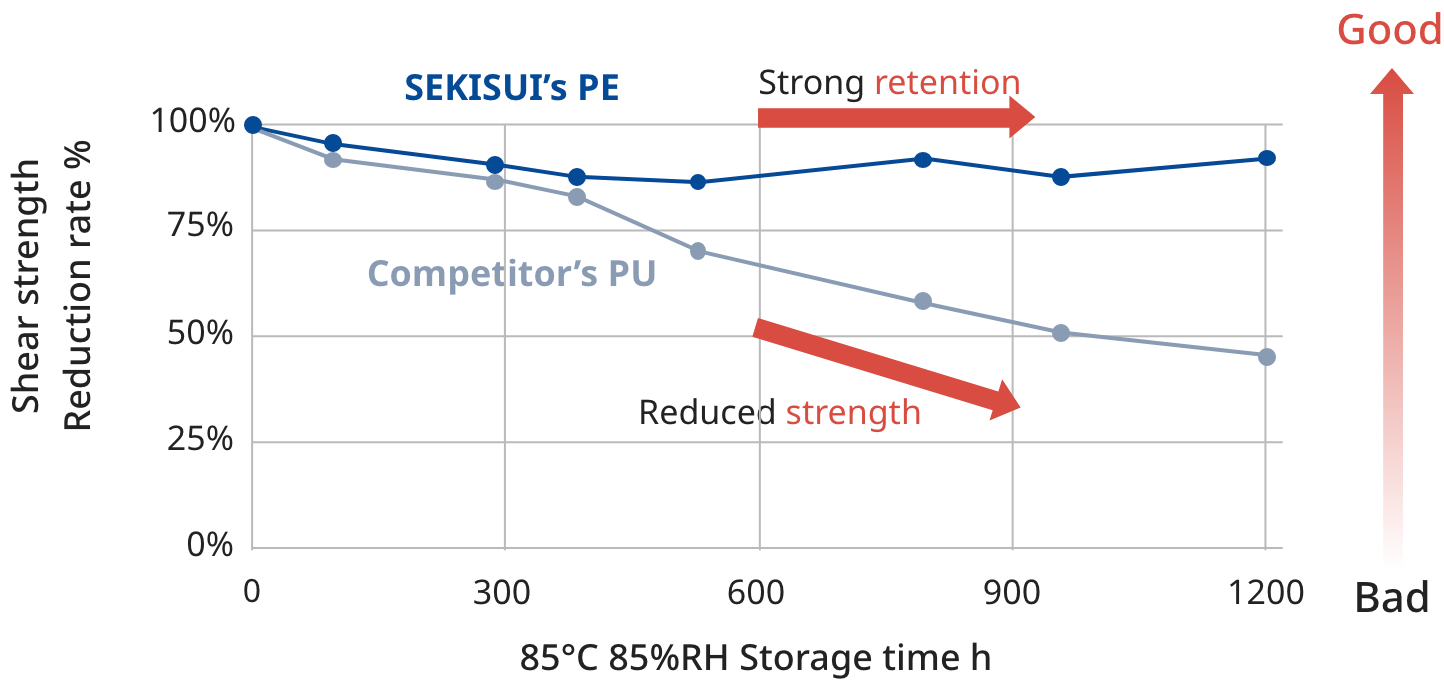

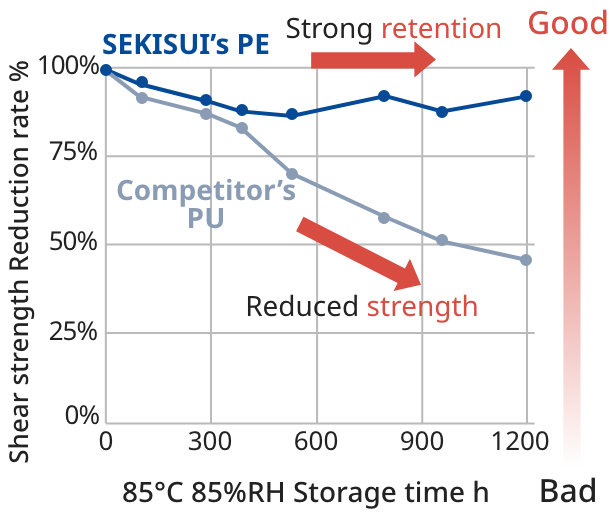

3Strong hydrolysis resistance performance

CheckShear tensile test in hot and humid conditions

Evaluation method

- SUS objects are stuck together with a 25mm×12.5mm piece of tape and left for 24 hours to cure, and then the shear strength is measured.

- They are left in 85°C, 85% RH conditions and the shear strength is measured at intervals until 1,250 hours have passed.

- With the shear strength at 0 hours as the baseline (100%), the relative strength (%) at each measurement time point is calculated.

| Adherend | SUS/SUS |

|---|---|

| Tape size | 25mm × 12.5mm |

| Pressure application conditions | 5kg × 10sec |

| Curing conditions | 2After 24h at 23°C, 50%RH, store at 85°C, 85%RH |

| Test temperature | Remove from the oven to cool and then measure at 23°C, 50%RH |

| Test speed | 12.7mm/min |

Results

SEKISUI’s PE products retain base material strength even with long-term use as they do not deteriorate from hydrolysis.

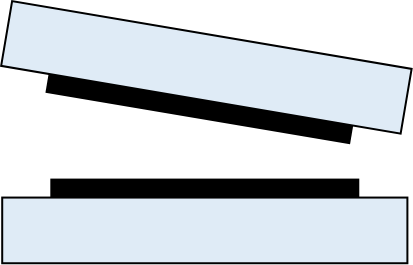

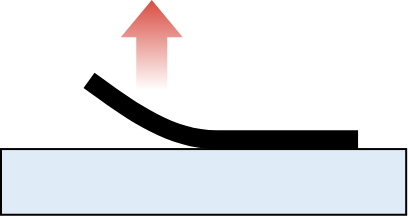

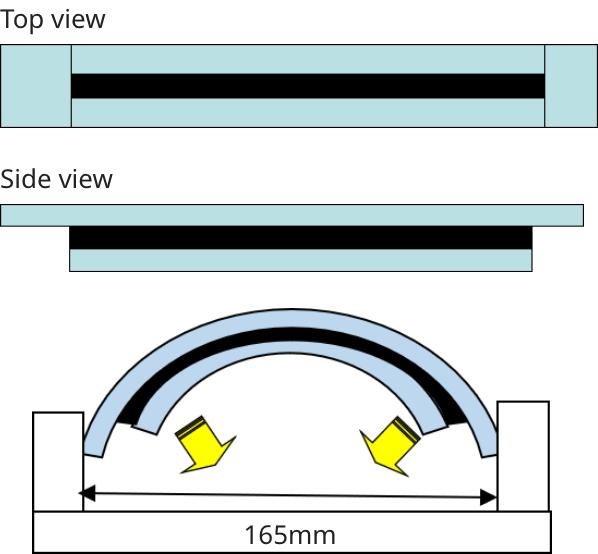

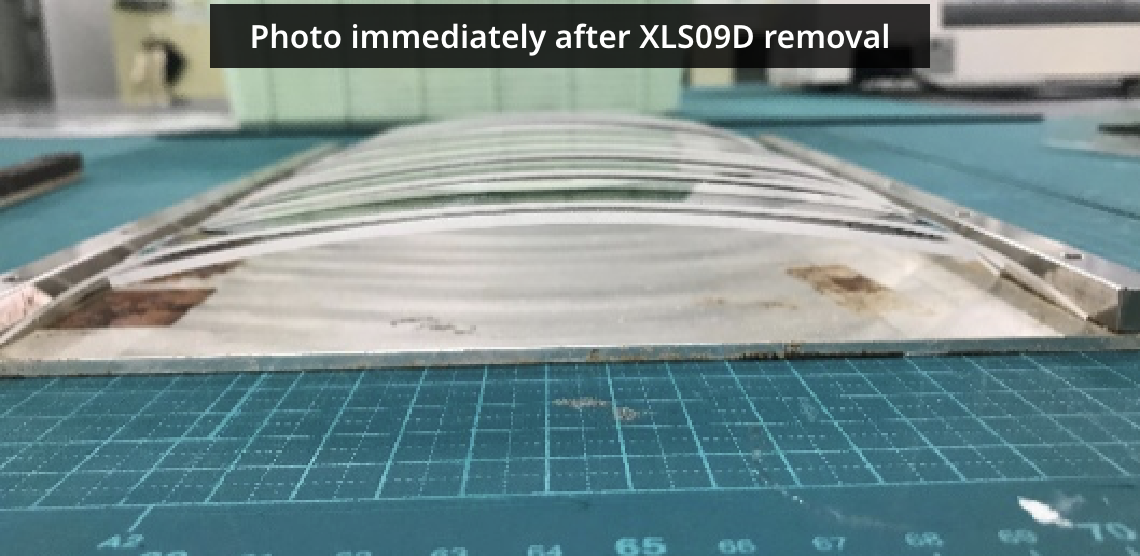

4Curved surface tracking performance

Simulated situation for evaluation

Tested assuming use on a curved screen with the housing as the PC adherend.

Evaluation method

- Two pieces of PC board are taped together, clamped, and left for 24 hours.

- The PC boards are bent and checked for lifting and peeling of the tape.

| Evaluation part number | XLS9D |

|---|---|

| Adherend 1 | PC board 2mm × 25mm × 150mm |

| Adherend 2 | PC board 1mm × 25mm × 200mm |

| Tape size | 3mm × 150mm |

| Pressure application conditions | 2 kg roller × 1 time in both directions (10 mm/sec) |

| Curing conditions | 23℃ 50%RH*24hr |

| Test temperature | 60℃ 90%RH |

*With a chord length of 165 mm and arc length of 200 mm, R (radius) = 95 mm (actual R is 95 mmv due to PC rigidity<)

Results

| Evaluation time | Lifting distance |

|---|---|

| After 1 hour | 0mm |

| After7days (168 hours) |

0mm |

XLS09D has excellent repulsion resistance against PC adherends.

Product Lineup

| Series | Feature | Tape Thickness (μm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 660 | 860-900 | 1200-1260 | 1600 | 1800 | ||

| XUM | High flexibility | ー | ー | ー | XUM066D-3 | XUM086D | XUM12D | XUM166D-1 | ー |

| XLS | High strengthe | XLS03D | XLS04D | XLS05D | XLS066D | XLS09D | XLS12D | XLS166D | XLS18D |

*Note: Other thicknesses are available upon request

Applications

Application example of the Flexible Foam Tape

Are you experiencing these issues? Our sales and technical support team will help you

- You are having problems with retention strength of your current tape

- You want to strongly support a heavy load even with a small tape surface, etc.