_防水・衝撃吸収フォームテープ 5200_png_w500px_h500px.png)

- Electronics

- Sustainability

Waterproof/Shock-Absorbing Foam Tape 5200 Series

A heat-resistant foam tape that delivers both waterproofing and shock absorption

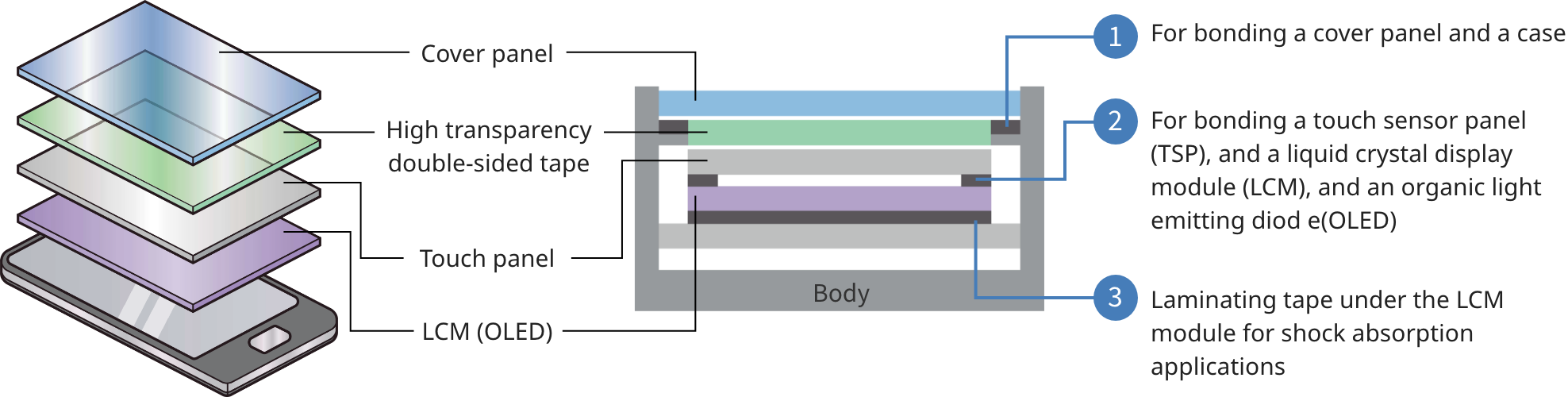

A functional foam tape made from a PE or PP resin foam substrate combined with a high-adhesion adhesive. It provides excellent waterproofing, dustproofing, and impact absorption, while also offering outstanding conformability to uneven surfaces. Ideal for cushioning and bonding applications in precision devices such as smartphones and in-vehicle displays, it maintains reliable adhesion even under high temperatures and complex shapes.

- Electronics

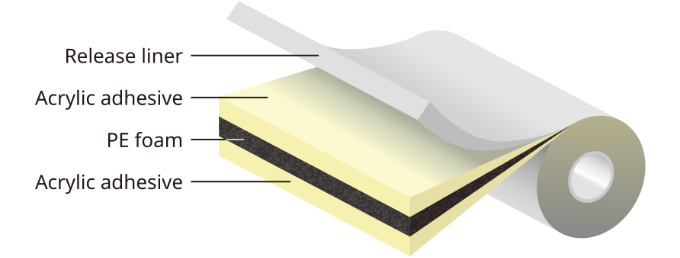

Structure & Features

- Foam tape has strong adhesive strength and durability to absorb high impacts.

- Bond well onto uneven surface and excellent water and dust-proof capability.

- Excellent repulsion resistance and strong adhesion to bond to a curve surface of objects

- Available in grades that do not lose performance in 105°C conditions

Features

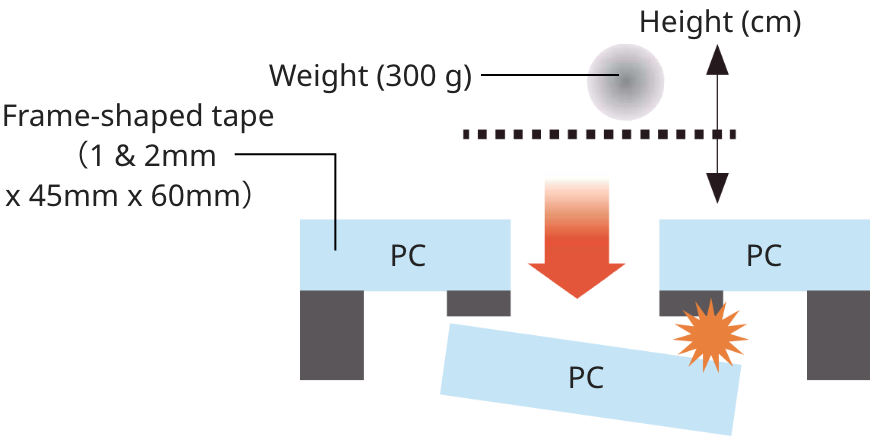

1High drop impact resistance

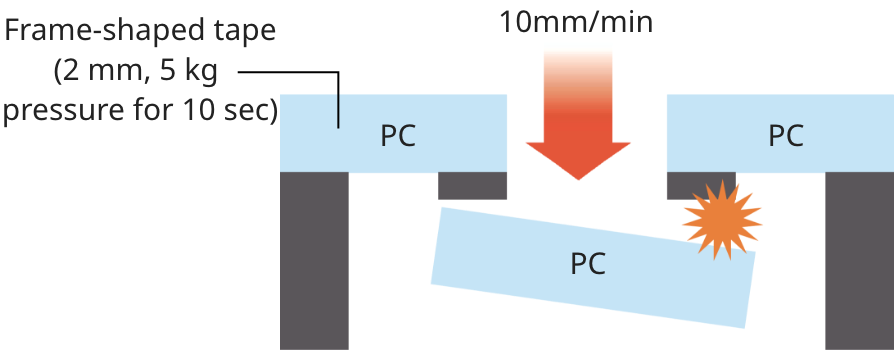

CheckDrop impact test

Evaluation method

- Cut a 3-inch squuare out of the sample tapes with a width of 2mm and 1mm respectively, and stick each of them to a PC board with its center cut.

- After that, apply a pressure of 5 kg to it for 10 seconds.

- Leave the board at the normal temperature for one day, and drop a weight on its center to measure the height from the point where the weight was dropped to the point where the PC board peeled and fell off.

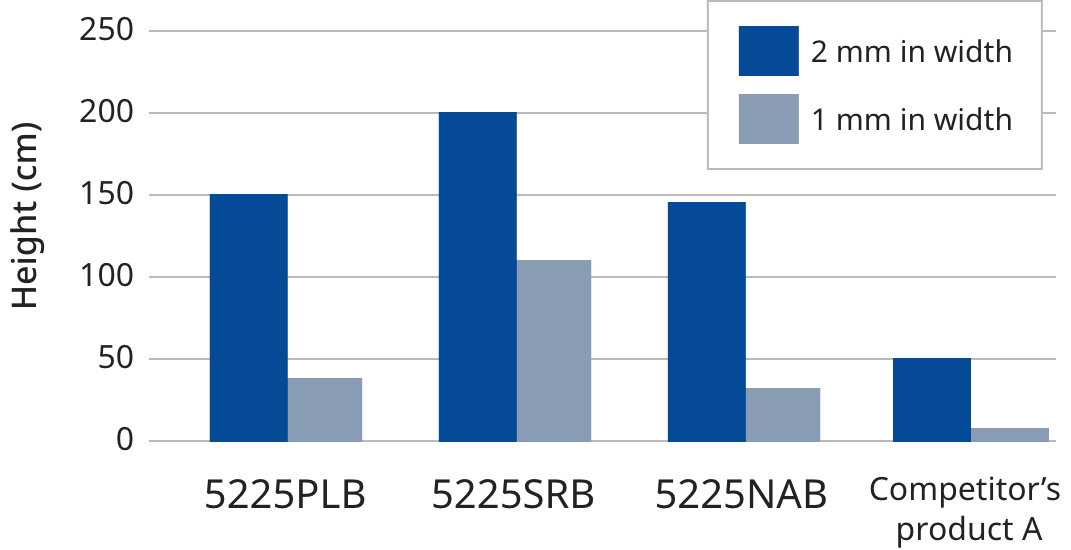

Results

Exerts excellent impact absorption even when narrow.

2Strong adhesion properties

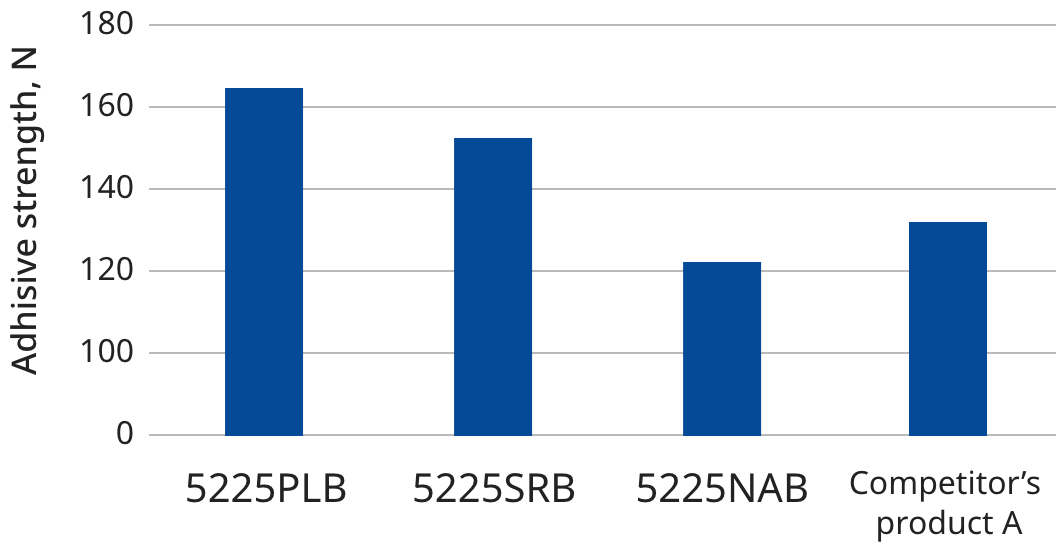

CheckAdhesion test (Push test)

Evaluation method

- Stick a sample tape on the PC board.

- Put an adherend on the tape with a weight of 5 kg for 10 seconds. Do the same thing with other adherends.

- Leave it at the normal temperature for one day, and press it through the hole as the picture shows to measure how much weight is needed until the adherend departs from the PC

Results

Strong adhesion that keeps it from peeling easily.

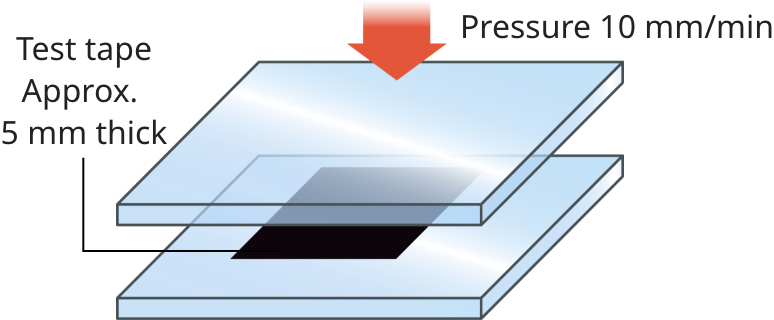

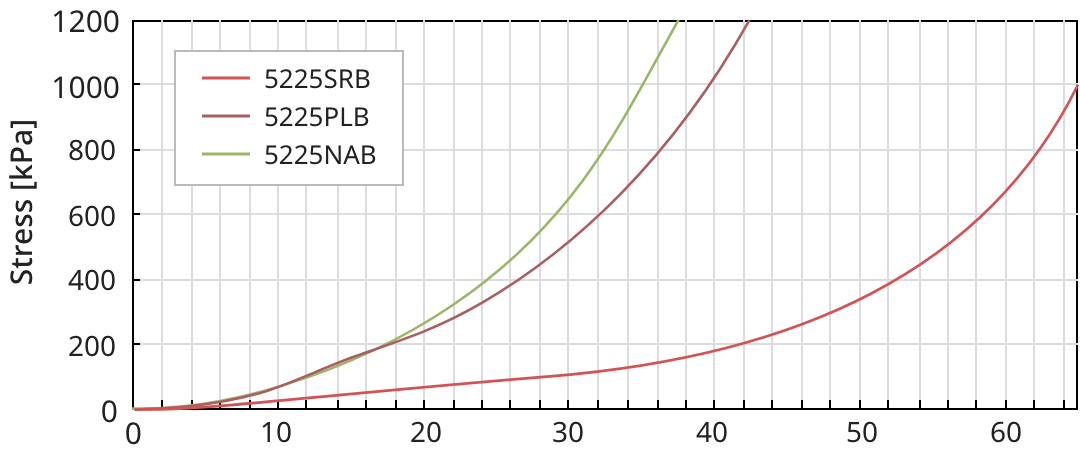

3Strong flexibility

Evaluation method

- Stack pieces of test tape 5 mm thick and apply pressure to the surface.

- Measure the amount of warping with the pressure applied and measure the flexiblity.

Results

Has excellent flexibility and the degree of flexibility can be chosen for the application.

4Strong heat resistance

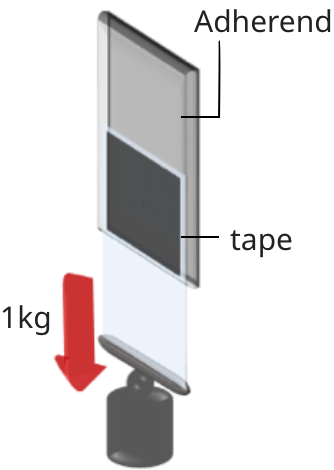

CheckHeat resistance retention test

- Stick two adherends together and apply a weight on one side in the shear direction.

- Put in various temperature conditions for a long period and check if the weight causes it to fall.

Shear direction

| Tape | 52110PSB / 52110PPB |

|---|---|

| Adherend | SSUS board |

| Clamp condition | 23°C, 1 pass back and forth with a 2-kg roller |

| Temperature condition | 105℃ |

| Size | 25mm × 25mm |

| Static load | 1kg |

Results

| Test conditions | Results | ||

|---|---|---|---|

| Temperature | Time | 52110PSB | 52110PPB |

| 105℃ | 1000h | ○ | ○ |

| -40℃ | 1000h | ○ | ○ |

| -40℃ ⇔ 105℃ | 200cyc | ○ | ○ |

○: No fall,×: Fall

Confirmed strong resistance to shear direction deviation in high temperatures in both grades.

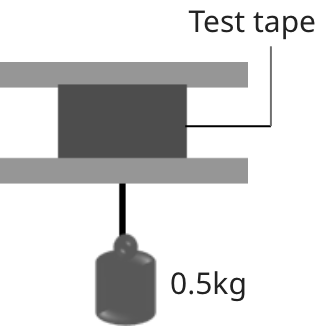

Both directions

| Tape | 52110PSB / 52110PPB |

|---|---|

| Adherend | SUS board |

| Clamp condition | 23℃、0.3MPa × 10s |

| Temperature condition | 105℃ |

| Size | 25mm × 25mm |

| Test conditions | 0.5kg、 1000h |

Results

| Test conditions | Results | |

|---|---|---|

| Static load | 52110PSB | 52110PPB |

| 0.5 kg | ○ | ○ |

○: No fall,×: Fall

Sekisui products deliver strong high-temperature holding power even in the direction where the load is greatest.

Product Lineup

- How to read the model number

-

52

201

N2

S3

B4

- 1Tape thickness

- 2Type of foam substrate

- 3Type of adhesive

- 4Foam color(B→black,W→white)

| Features | 100μm | 150μm | 200μm | 250μm | 300μm | 350μm | 400μm | 600μm | 900μm | 1100μm | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NSB | Standard toluene-free |

5220NSB | 5230NSB | 5240NSB | 5260NSB | 5290NSB | 52110NSB | ||||

| PSB | Specialty waterproof | 5215PSB | 5220PSB | 5225PSB | 5230PSB | 5235PSB | 5240PSB | 5260PSB | 5290PSB | 52110PSB | |

| NAB | Medium strength toluene-free |

5210NAB | 5215NAB | 5220NAB | 5225NAB | ||||||

| PLB | Strong | 5215PLB | 5220PLB | 5225PLB | 5230PLB | ||||||

| PMB | Extra strong | 5210PMB | 5215PMB | 5220PMB | 5225PMB | 5230PMB | |||||

| SRB | Flexible medium strength toluene-free |

5225SRB | 5230SRB | 5235SRB | 5240SRB | ||||||

| PPB | Heat resistant | 5220PPB | 5230PPB | 5240PPB | 5260PPB | 52110PPB |

Applications

Are you experiencing these issues? Our sales and technical support team will help you

- Tape peels off in a drop test / Cannot pass waterproof test

- I want to further increase device strength, etc.