No ignition and deformation

Surface resin carbonizes and expands

Surface resin carbonizes and expands Inner surface remains unchanged

Inner surface remains unchanged Contact

Contact

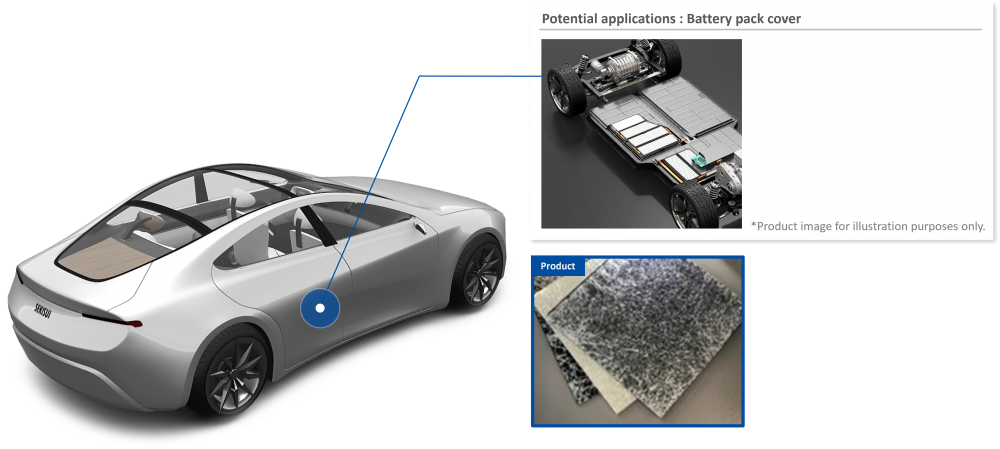

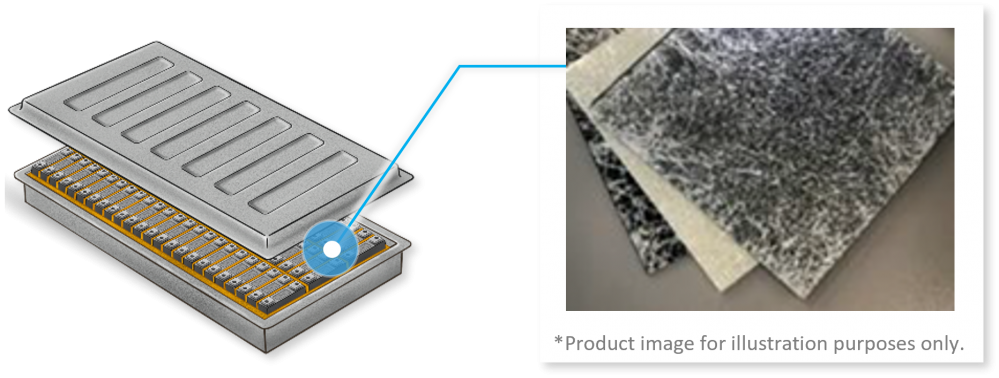

Flame-retardant sheet for EVs that achieves both ignition risk suppression and weight reduction

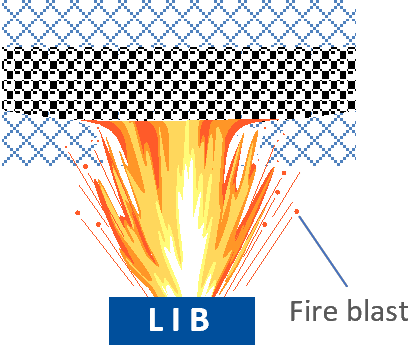

While lithium-ion batteries (LiBs) in electric vehicles (EVs) generate high-output energy, they contain a combustible electrolyte that can cause thermal runaway with malfunction or heavy impact. Currently, steel or aluminum covers which combined with inorganic sheets are used on LiBs to prevent heat and flames from entering the vehicle in the event of a fire, but aluminum adds significant weight, which affects the travel distance of EVs. In order to improve the travel distance of EVs in the future, LiBs must have a higher capacity, reduce weight while maintaining safety.

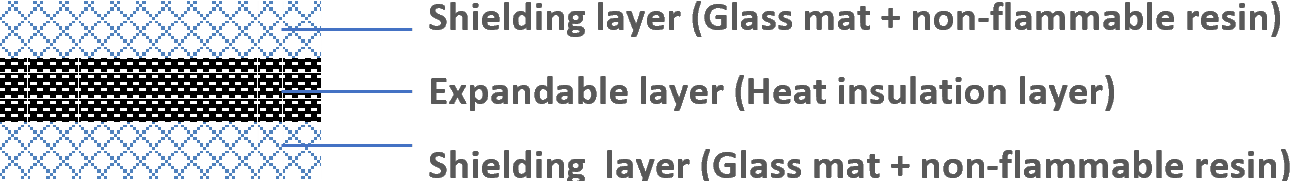

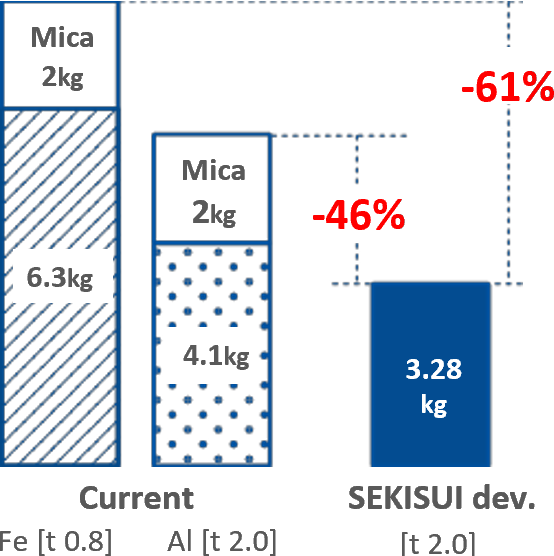

To address these issues, SEKISUI has developed a thermoplastic sheet with triple performances of fire retardant, flame shielding, thermal insulation. The weight can also be reduced by up to 61% compared to aluminum.

Non-flammable

Self-extinguishing,

Non-perforated

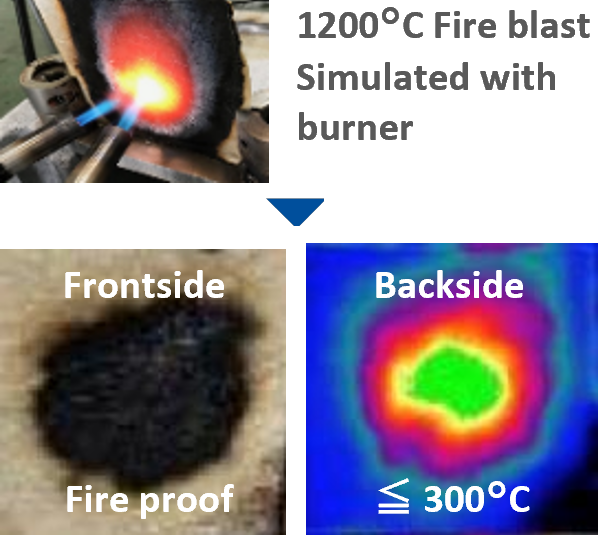

Strong resistance to fire blast

Surface ≦ 300℃

Vehicle fire prevention

Light weight

Max 61% weight reduction

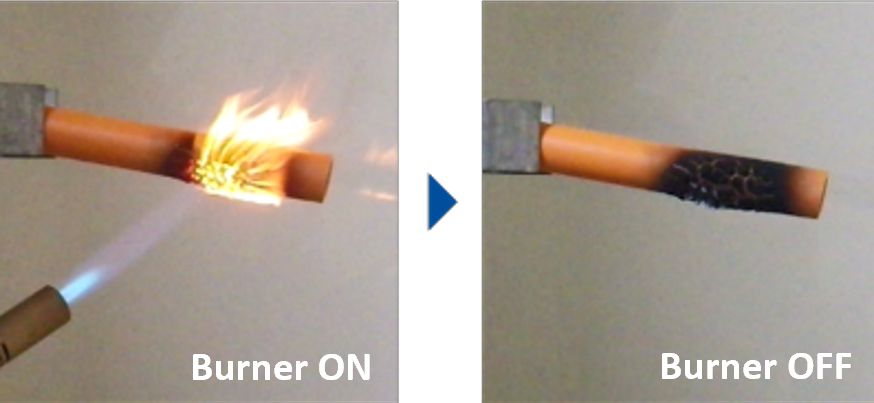

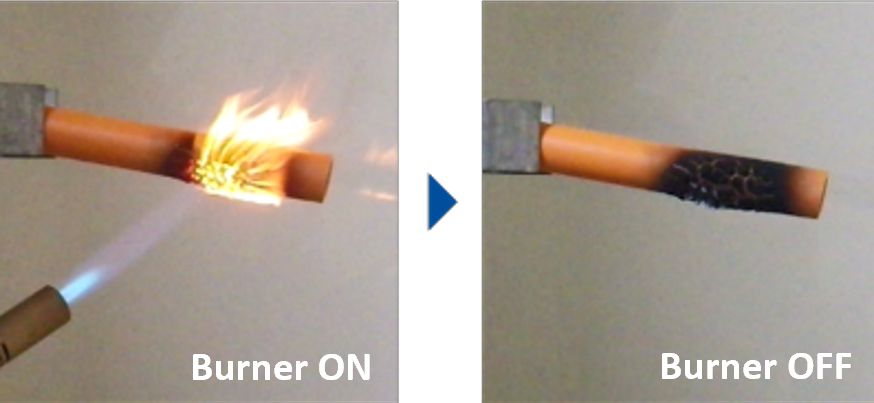

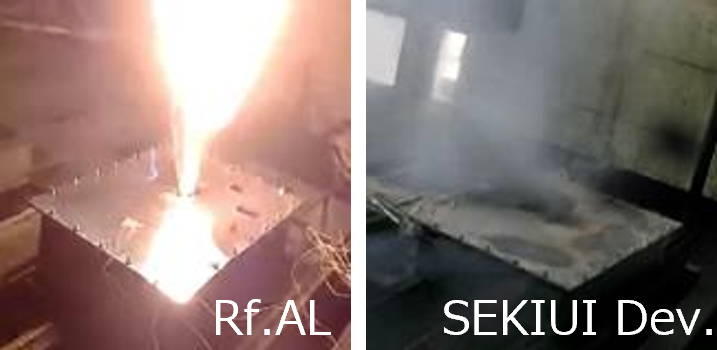

Burning test

[Test condition] Apply the flame torch to the developed material for 30 seconds

No ignition and deformation

Surface resin carbonizes and expands

Surface resin carbonizes and expands Inner surface remains unchanged

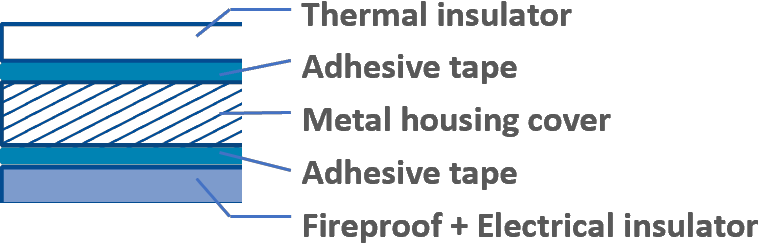

Inner surface remains unchangedStructure

Cell runaway test

[Test condition]

Surface temp. ≦ Spontaneous combustion of interior parts

Fire blast test

Spontaneous combustion of interior parts

| Interior parts | Fire point (°C) |

|---|---|

| Seat (Polyurethane form) |

415 ℃ |

| Floor mat (Polypropylene fiber) |

400~570 ℃ |

| Floor carpet (Polyester fiber) |

490~560 ℃ |

Solution (stacked structure) comparison

Weight comparison

[1.5m2 estimate]

| Name | Type | File | Update | File |

|---|---|---|---|---|

| Catalog 〈Mobility〉:Flame retardant lightweight composite sheet_SekisuiMobilitySolution | Mobility | 2023-09-11 | Download1.06 MB |