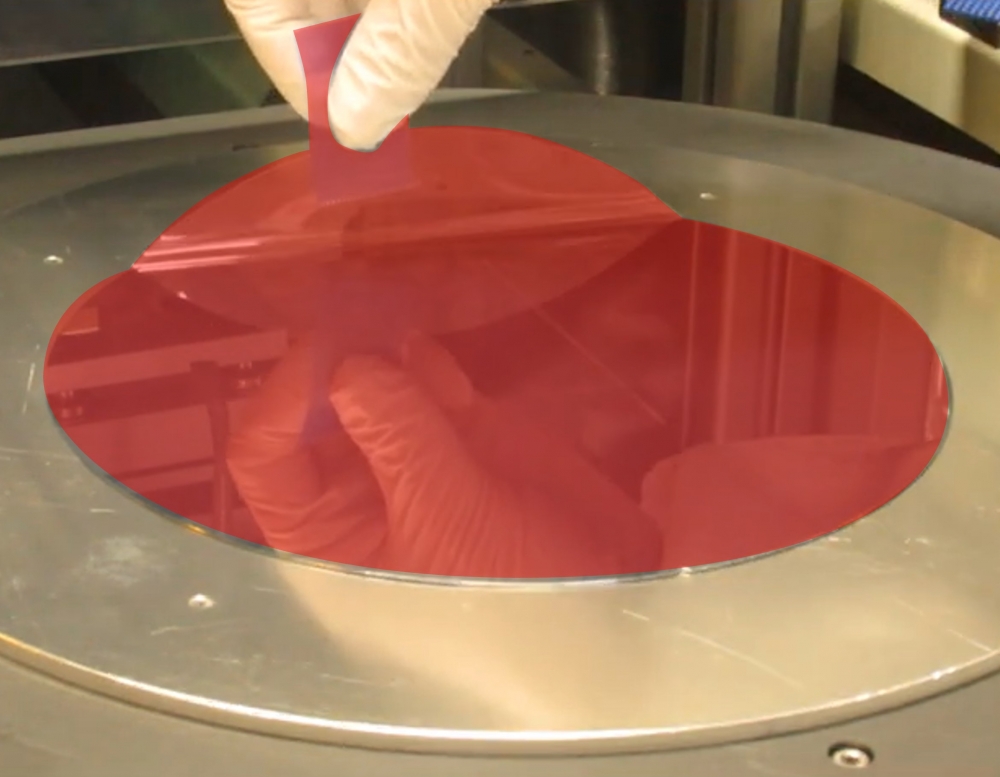

SELFA - high adhesion easy removable UV tape -

-Challenge- Prevention of damage to semiconductor wafers

-Challenge- Prevention of damage to semiconductor wafers

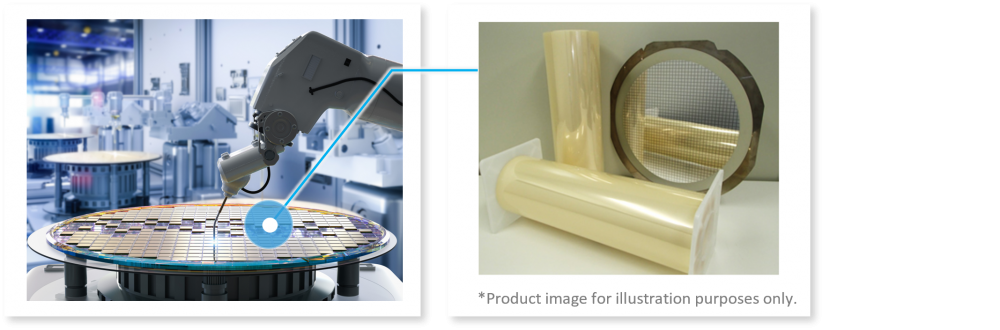

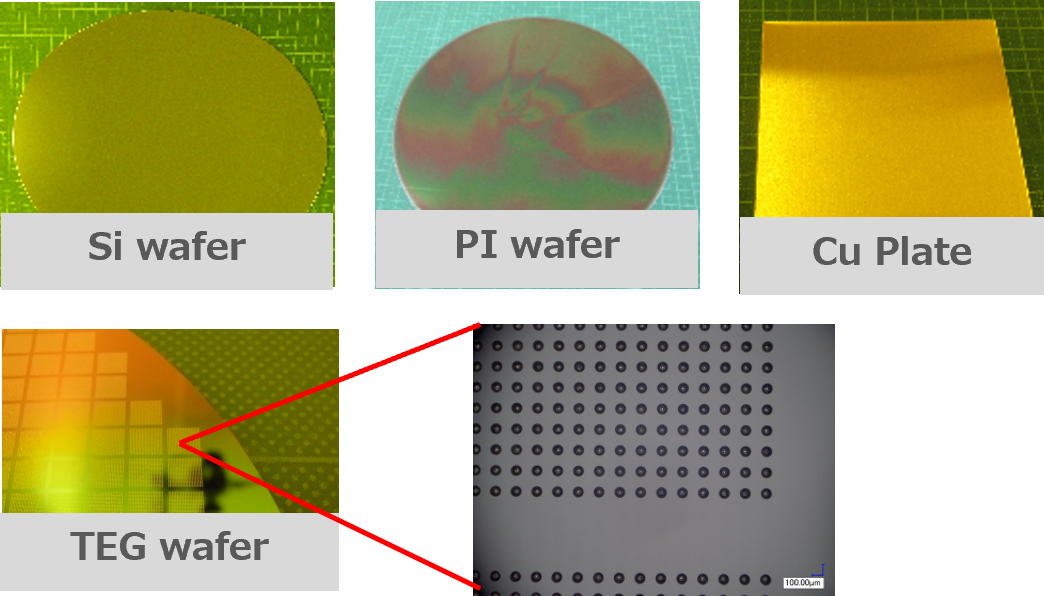

When manufacturing semiconductor wafers, the wafers must be firmly fixed during the polishing process, and this process poses a risk of damaging the expensive wafers when removing the holding materials.

-Solution- UV irradiated release tape with high adhesion and easy release

-Solution- UV irradiated release tape with high adhesion and easy release

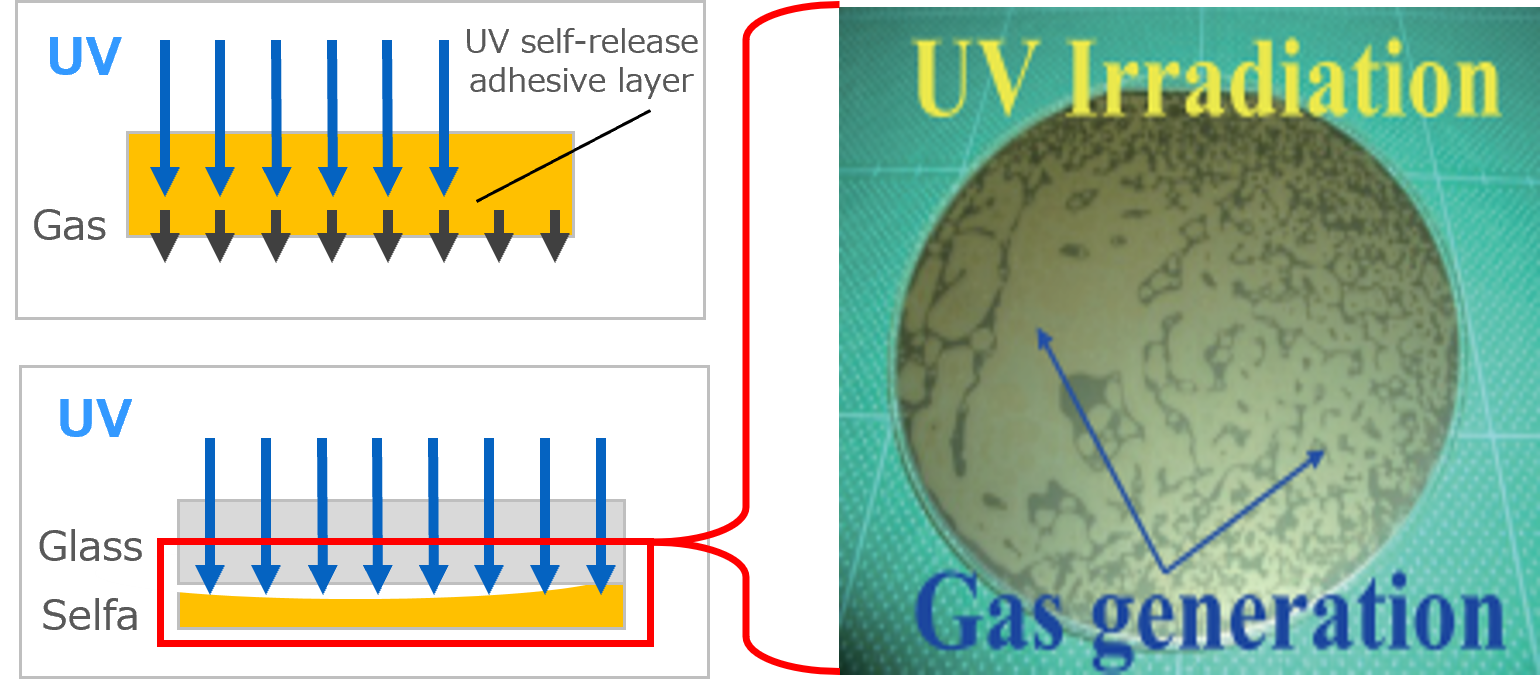

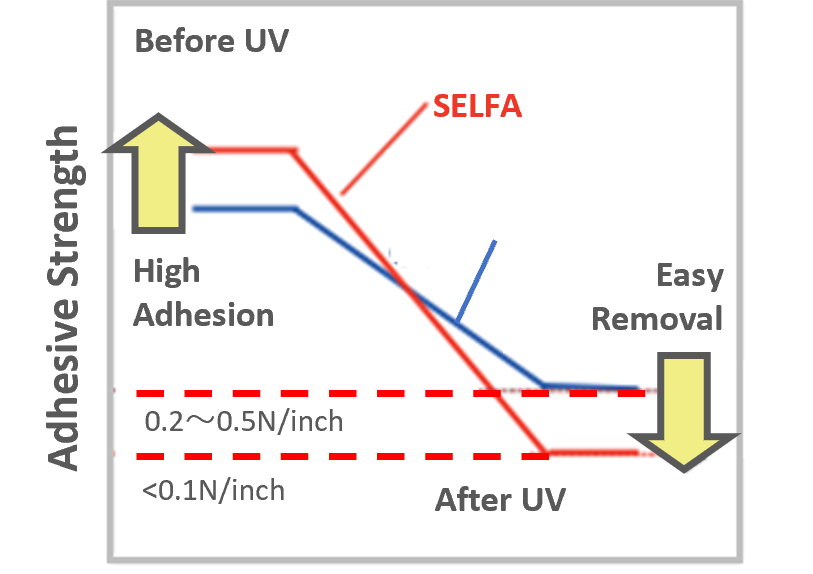

The SELFA series is a removable UV tape that achieves strong adhesion and easy peeling. Gas is generated between the tape and the adhered by UV irradiation, and the tape can be easily removed with no adhesion, making it possible to process thinly polished wafers without damage. We will propose the optimal grade from a wide lineup such as single-sided SELFA HS with high-heat resistance, SELFA HW heat-resistant temporary bonding materials, and SELFA MP with excellent chemical resistance.

-Technology- Technical information

-Technology- Technical information

Technical overview

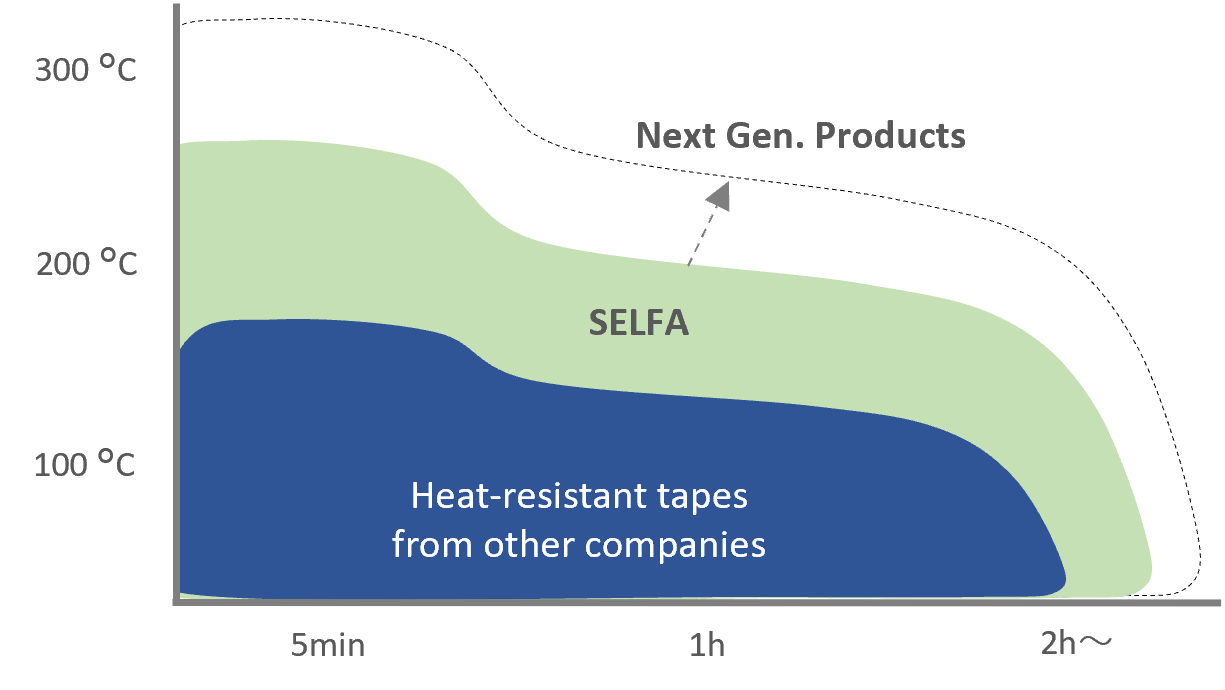

Heat resistivity

Heat resistivity

Heat resistance of 220°C × 2hours is guaranteed.

Excellent low-residue properties.

Proven record of use in reflow, annealing,

sputtering, CVD, and other heat processes.

Chemical resistivity

Chemical resistivity

Adaptability to a wide variety of chemicals

Electroless plating, roughening,

resist exposure/development, chemical cleaning, etc.

Gas debonding

Gas debonding

Sekisui's proprietary "gas debonding" technology

realizes easy peeling from adherends.

We have a track record of peeling from sensitive

substrates such as glass and wafers.

Easy-handling

Easy-handling

Easy to handle, tape-type solution

Process construction is possible with

general-purpose and inexpensive manufacturing equipment.

Technology details

Heat resistivityThe heat resistance is 220°C×2hours or 260°C×5minutes,

Heat resistivityThe heat resistance is 220°C×2hours or 260°C×5minutes,

with the aim of further improving heat resistance.

Chemical resistivityAdaptability to a wide variety of chemicals.

Chemical resistivityAdaptability to a wide variety of chemicals.

| Item | Solvent | Temperature(°C) | Process time (sec) | Weight loss (wt%) |

|---|---|---|---|---|

| 1 | Tetra Hydro Furfuryl Alcohol 75-100% | 60 | 420 | ≤1 |

| 2 | NMP | 50 | 3000 | ≤1 |

| 3 | KOH 1% | 25 | 90 | ≤1 |

| 4 | CuSO4 18% | 4200 | ≤1 | |

| 5 | H2SO4 5-10% | 4200 | ≤1 | |

| 6 | HCI 6% | 4200 | ≤1 | |

| 7 | Acetic Acid 10% | 60 | ≤1 | |

| 8 | HF 0.5% | 900 | ≤1 | |

| 9 | NH4OH 30% | 900 | ≤1 | |

| 10 | PGME | 900 | ≤1 | |

| 11 | PGMEA | 900 | ≤1 | |

| 12 | TMAH 2.38% | 7200 | ≤1 | |

| 13 | IPA | 900 | ≤1 | |

| 14 | C6H8O7 5% | 900 | ≤1 | |

| 15 | H2O2 30% | 900 | ≤1 | |

| 16 | KOH 5% | 900 | ≤1 | |

| 17 | DMSO | 900 | ≤1 |

Gas debondingUnique gas generation technology enables debonding with less stress.

Gas debondingUnique gas generation technology enables debonding with less stress.

Easy-handling

Easy-handling

- Applicable to adherends with special

surface geometries.

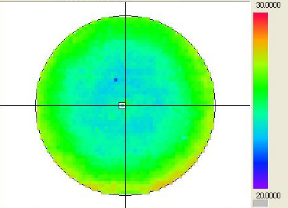

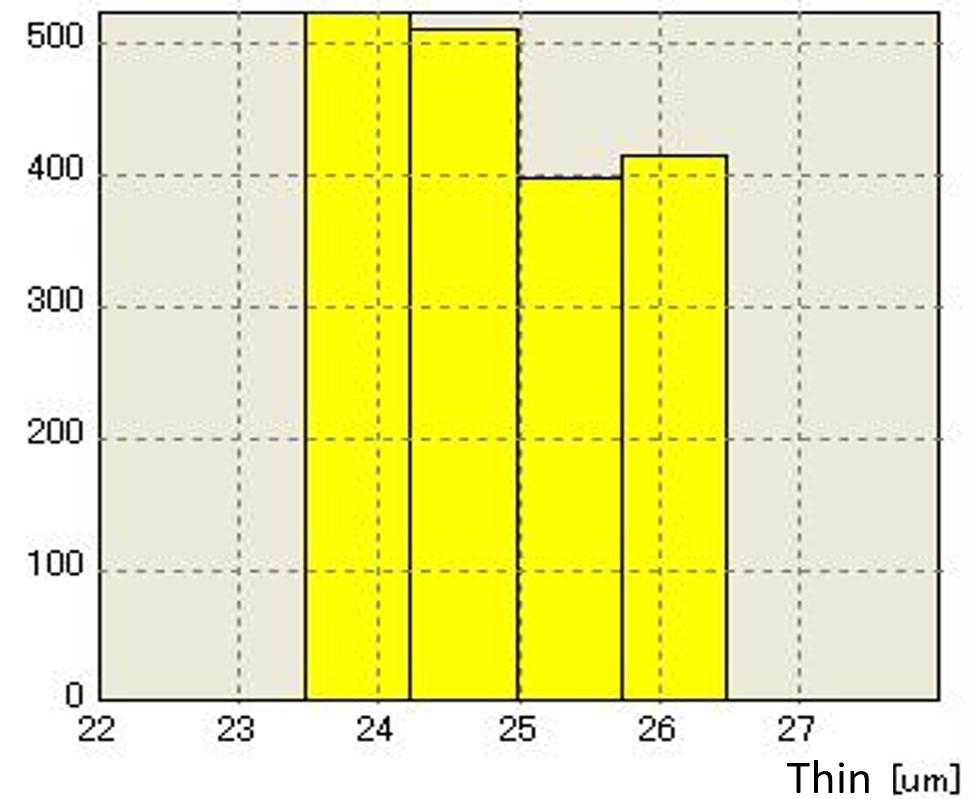

(e.g. MEMS, ubump, Taiko™ wafer, etc.) - Simple process control enables

good TTV performance. - The simplicity of the manufacturing process

makes it more cost-effective than other

temporary bonding technologies

(e.g. laser debond).

| Mapping |  |

|---|---|

| Histogram |  |

| THK | 24.9 um |

| TTV | 2.8 um |

Document download

認定証ダウンロードファイル一覧

| Name | Type | File | Update | File |

|---|---|---|---|---|

|

Catalog:SELFA - high adhesion easy removable UV tape -_SekisuiMobilitySolution |

Catalog |

2023-09-11 |

Download

1.37 MB

|

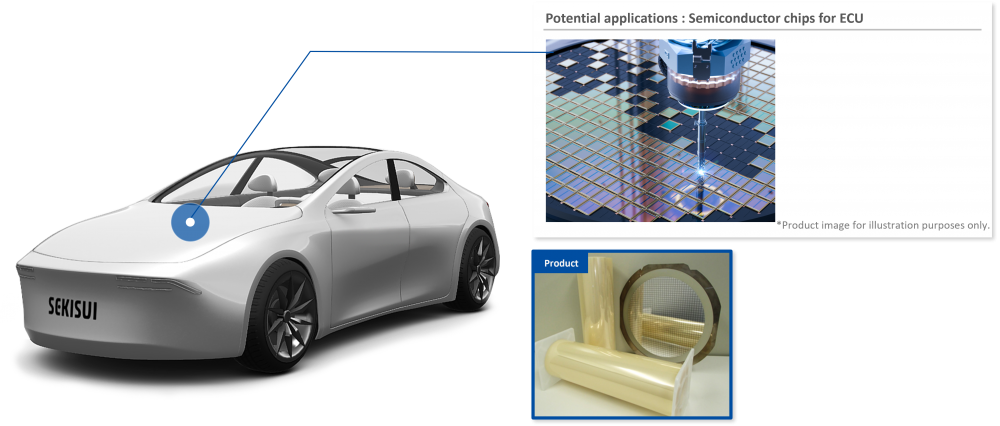

Sustainablity

Sustainablity Mobility

Mobility