_フォトレック™A_png_w500px_h333px.png)

UV light Curig Highly Transparent/ Black Adhesive Photolec™ A

A uv cure adhesive that combines light-shielding capability with strong adhesion

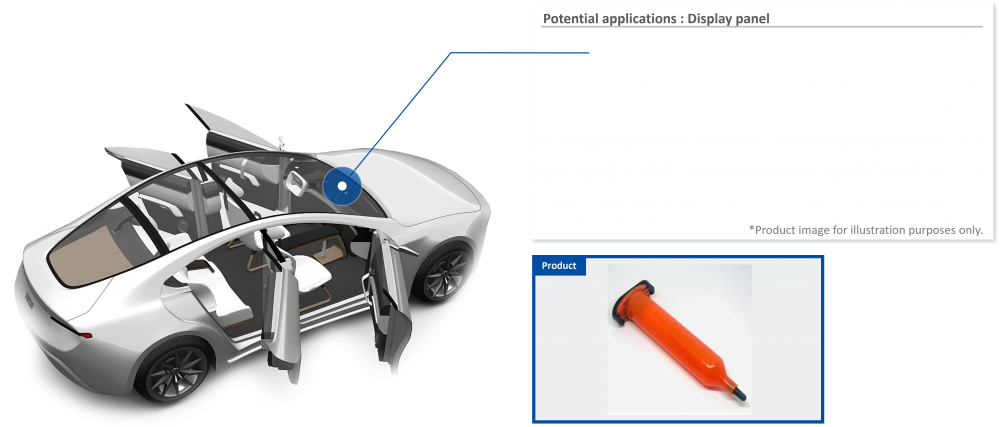

also supports a wide range of applications, including automotive camera modules, lens fixation, and CMOS sensor attachment.

- Mobility

- Electronics

- Moisture intrusion into the camera module

- UV fast-curing adhesive with excellent sealing reliability

- Technical information

- Document download

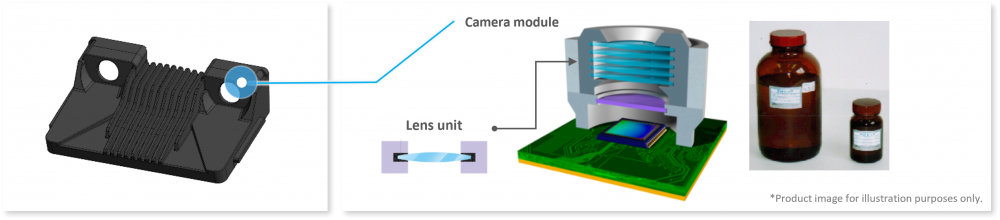

Moisture intrusion into the camera module

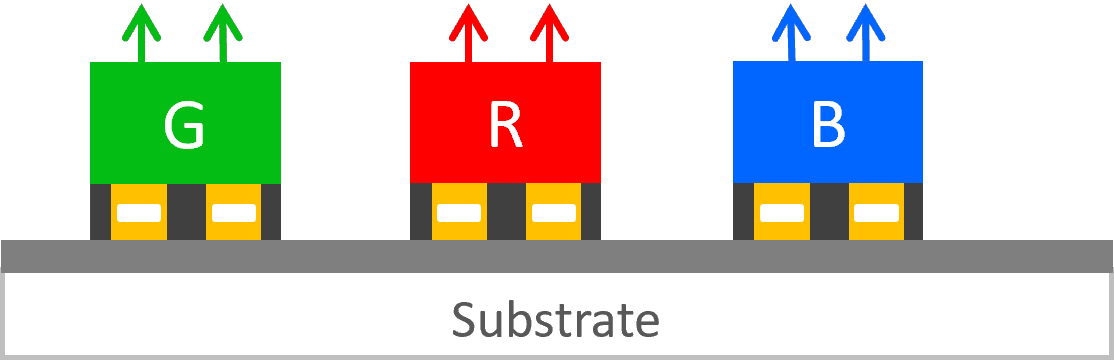

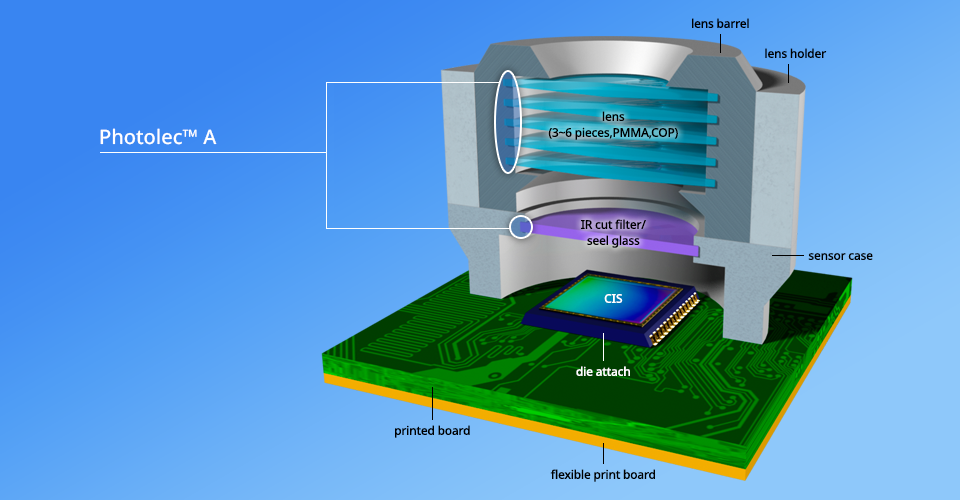

There are various sensors used in advanced driver assistance systems (ADAS), and in-vehicle cameras are one of the main sensors used in ADAS.

The technical challenges for the lens unit of camera modules include shortening of the curing time when attaching the lens, improvement of bonding strength, water entering the unit, and the light passing through the adhesive.

UV fast-curing adhesive with excellent sealing reliability

The UV-curing adhesive Photolec A is a UV-curing high-transparency adhesive ideal for attaching optical devices.

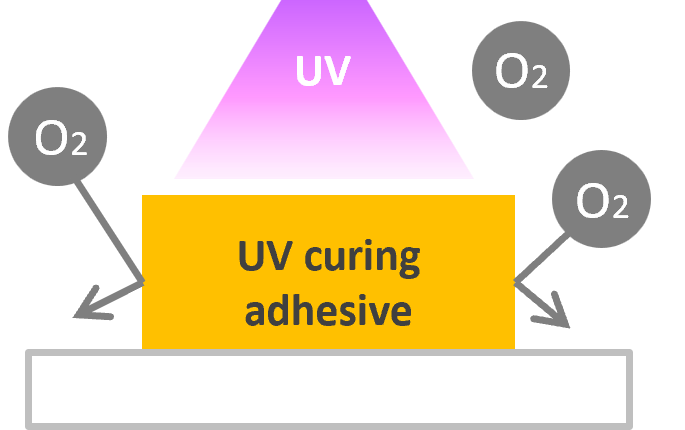

It cures quickly with UV light even when exposed to oxygen.

It has excellent adhesion to glass and securely holds lenses in place.

High resistance to water and excellent sealing reliability, preventing water from entering the module.

It can be made black (the black variant is also curable by UV irradiation), preventing light from passing through the adhesive around the lens.

Technical information

Technical details

UV curable

UV curable

Curing speed

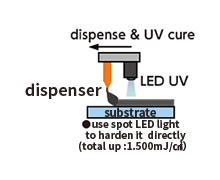

Cures quickly with UV even in an oxygen environment.

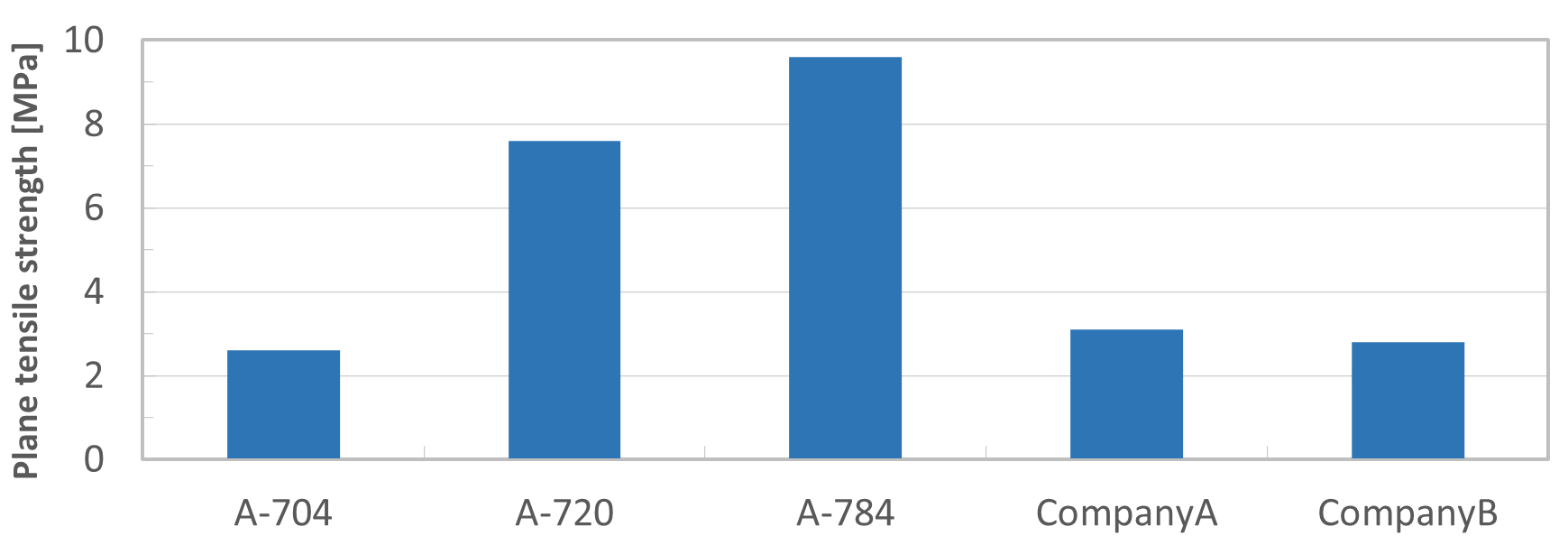

Adhesive strength

Adhesive strength

High adhesive strength

Excellent adhesion to glass substrates.

Low moisture permeability

Low moisture permeability

Sealing function

Impervious to moisture and excellent sealing reliability.

Light blocking

Light blocking

Blackening

Even black can be cured by UV irradiation.

Techinical details

UV curable

UV curable

Adhesive strengths

Adhesive strengths

Low moisture permeability

Low moisture permeability

| Standard | Black | |||

|---|---|---|---|---|

| A-785-180 | A784-60BK | |||

| Viscosity | 25℃ | MPa・s | 10,000 | 3,600 |

| Ti | 1rpm/10rpm | 1.03 | 1.03 | |

| WVTR | 60℃90% 300μm |

43 | 39 | |

| Storage conditions | 0 ~ 5°C, Shading | |||

| Use conditions | Normal temperature, UV cut environment | |||

Light blocking

Light blocking

protecting wiring and preventing light leakage.

Image drawing Glass 0.7mm

Image drawing Glass 0.7mmCharacteristics

- Low pollution, Halogen free

- Quick UV curing

- High transparency and refraction

- Suitable for situational manufacturing processes

- Low moisture permeation

- Reflow heat resistance (maintains transparency even after reflow)

- We have a black version of the resin that is also cured instantly with UV

Applications

1For optical uses

Fixing Optical Lens, CMOS Sensors

Excluding light at the edge

2For protecting glass substrates

Protecting base materials when etching them

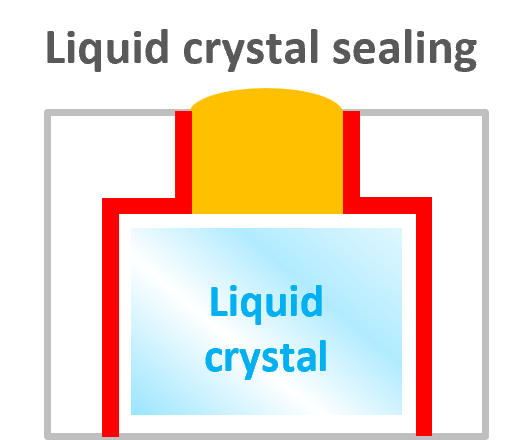

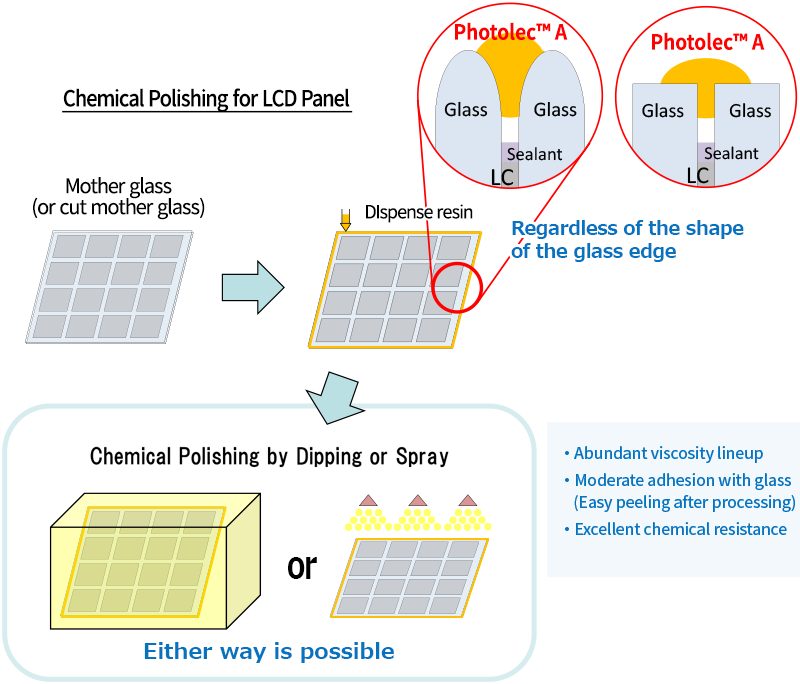

3For LCD use

LCD sealing,Moisture proof around the narrow bezel panel,light shielding

-

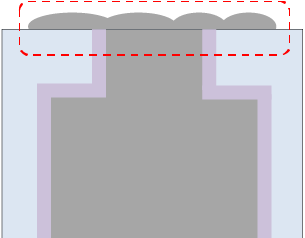

Wipe-off the liquid crystal

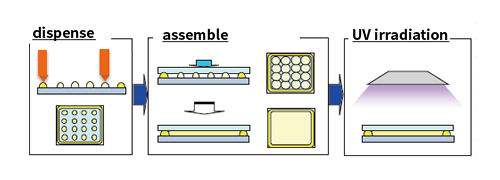

Wipe-off the liquid crystal- After injecting the liquid crystal, wipe off extra liquid crystal that is stuck onto the cross section of the panel

-

Dispense Photolec™ A

Dispense Photolec™ A -

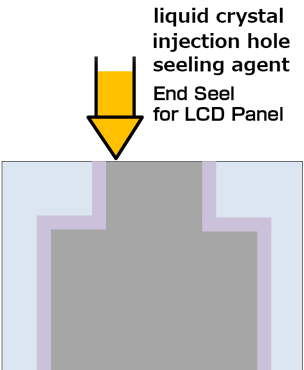

Permeation of sealant

Permeation of sealant- The encapsulant penetrates due to the negative pressure in the panel

- Penetration level (from cross section), Usually about 0.5 to 1.0 mm

-

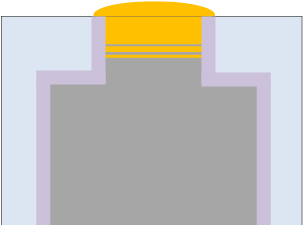

Hardening of sealant

Hardening of sealant- UV irradiation from cross section(UV irradiation from the side may damage the liquid crystal)

- The amount of light which can reach the liquid crystal interface is insufficient due to over-penetration

- When the interface is insufficiently cured, it may cause a detecting failure of the liquid crystal display screen

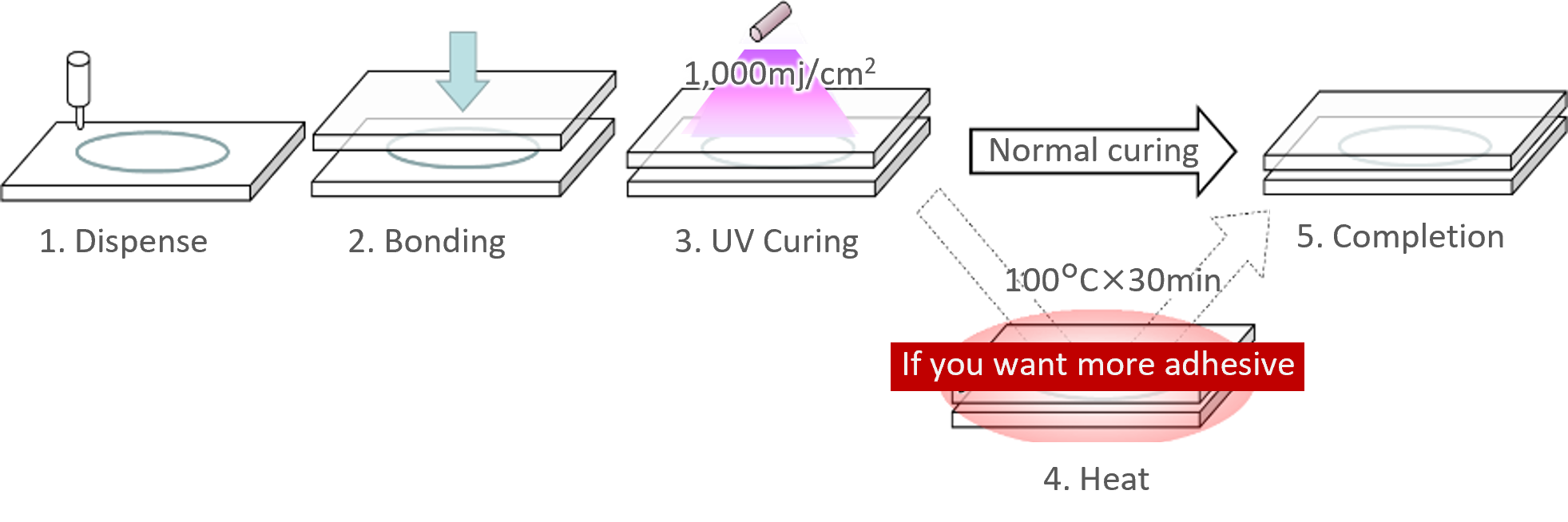

Sealant reacts (cures) with heat, the reaction with heat will increase the adhesion strength to the surface of the glass. We recommend applying heat during the annealing process (recommended conditions: 100℃ for at least 30 minutes)

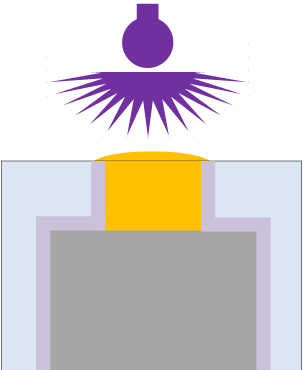

4Additional merits

This product can protect the electrode of FPC substrates

Process

Document download

- All

- Electronics

- Mobility

/新_フォトレックA_黒タイプ.png)