_EPOWELL™GP_png_w500px_h333px.png)

Adhesive with Precision Gap Control Particles EPOWELL™ GP

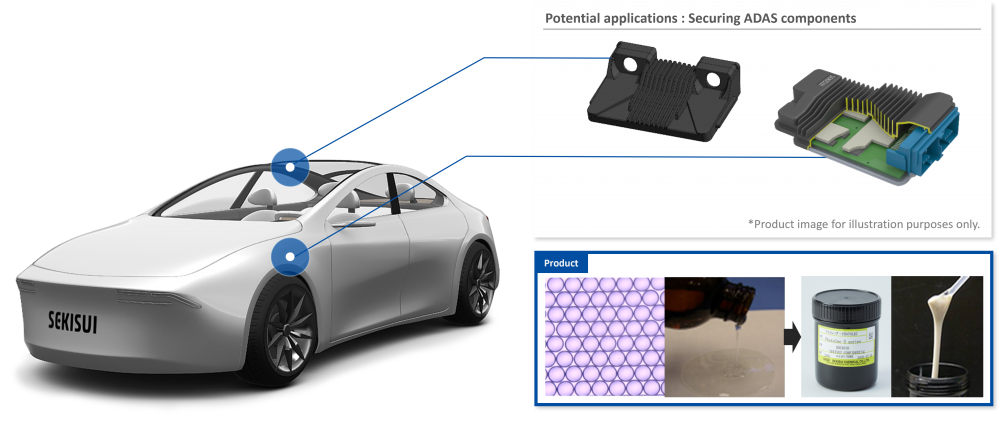

- Mobility

- Electronics

- Increased mounting difficulty due to smaller and thinner substrates

- Gap retention and high adhesion due to uniform particles

- Technical information

- Document download

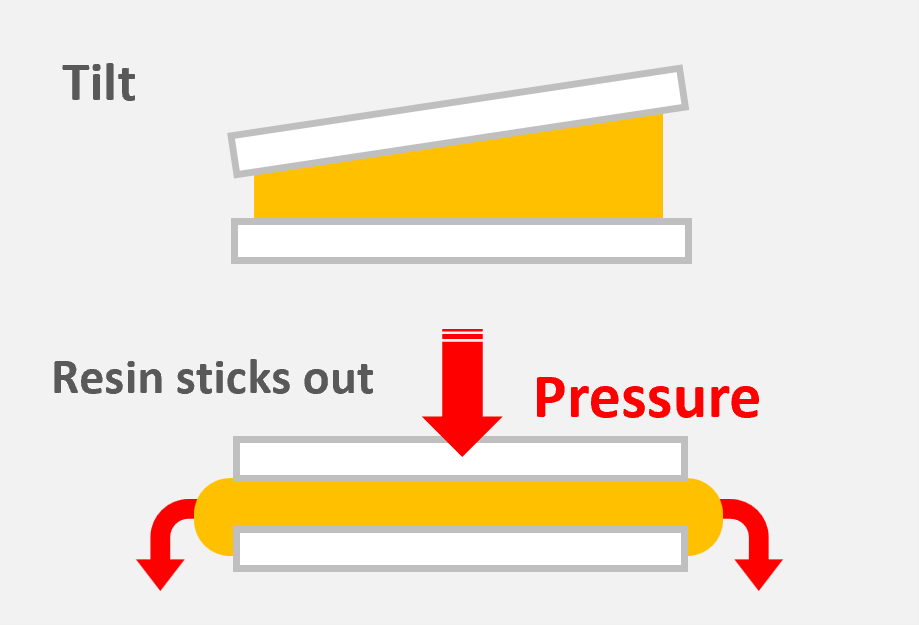

Increased mounting difficulty due to smaller and thinner substrates

As packages and PCBs continue to become more sophisticated, more compact, and slimmer, the technologies required for mounting them have also become more sophisticated, including lower gaps to achieve higher speed, uniform gaps for ensuring high reliability, countermeasures against circuit board warpage, and resistance to high temperatures and high humidity.

Gap retention and high adhesion due to uniform particles

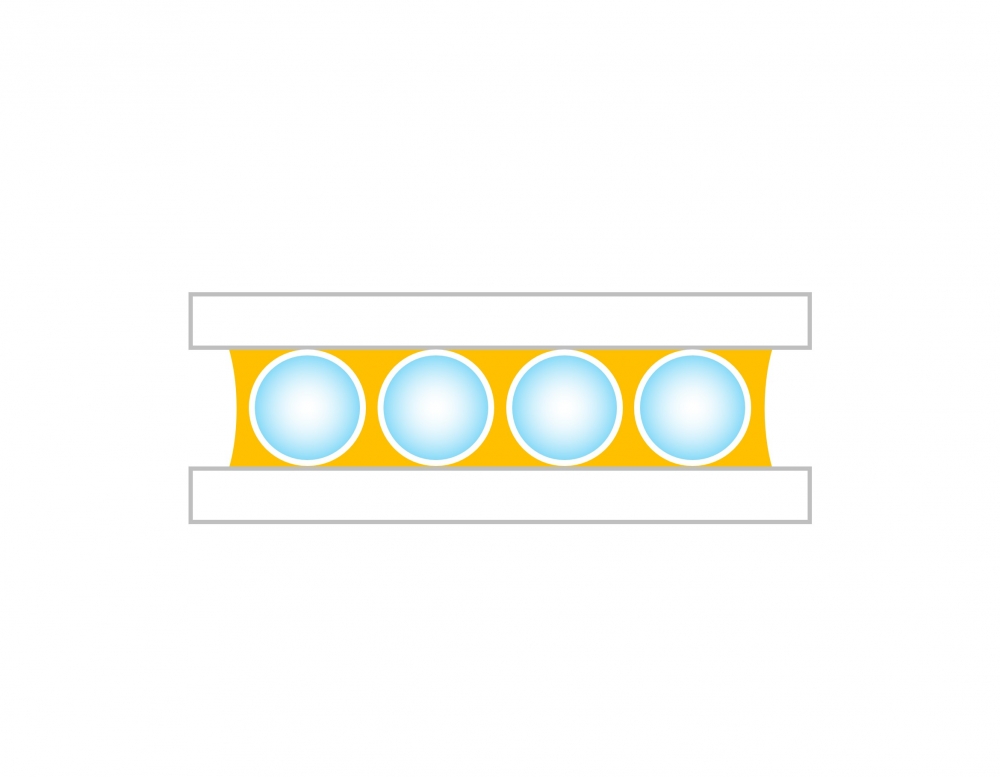

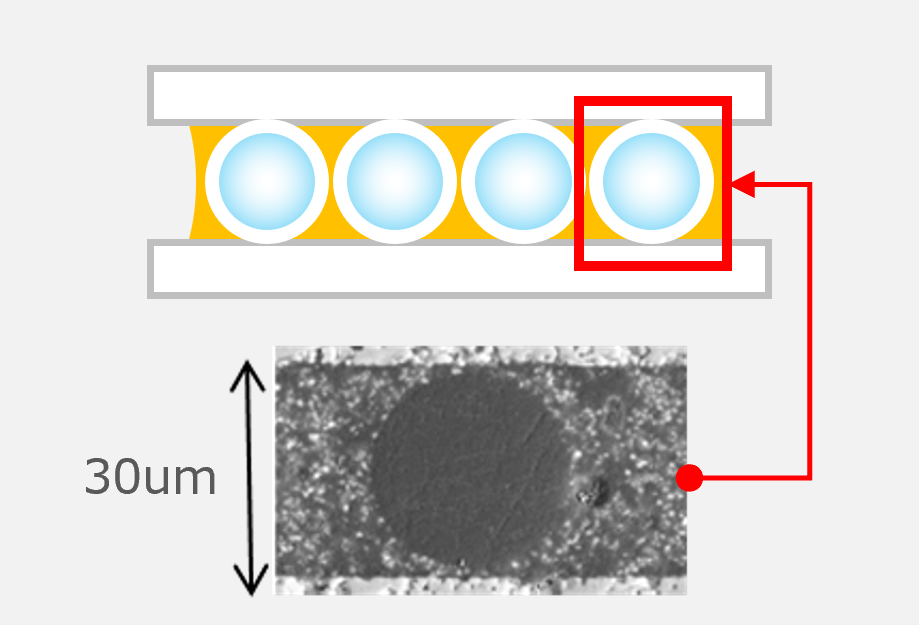

The Epowell GP series is a heat-curable adhesive formulated with ultra-precision spacers.

Uniform gap control contributes to improved gap retention and uniform adhesion.

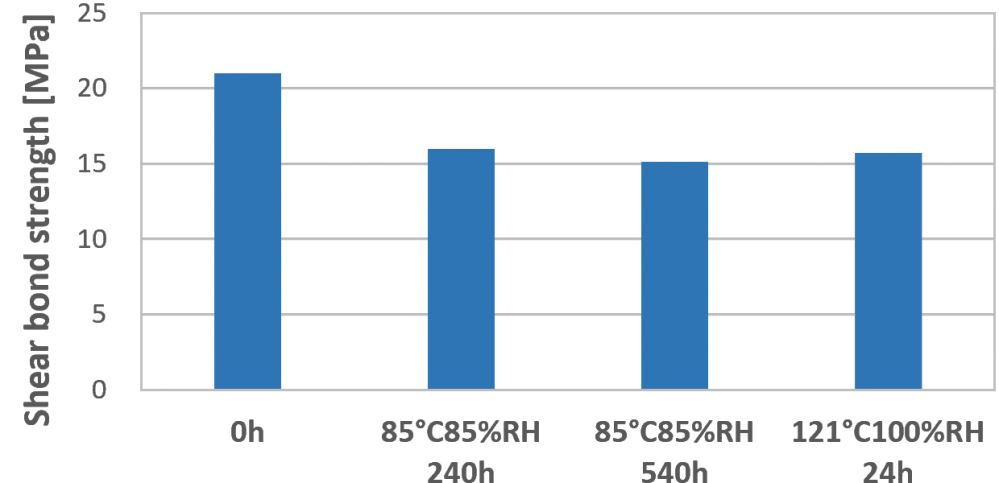

This series is compatible with high-temperature environments, and demonstrates stable adhesive strength even in a high-temperature and high-humidity environment.

A wide lineup of particle sizes from 15 μm to 500 μm enables precise gap control.

Technical information

Technical overview

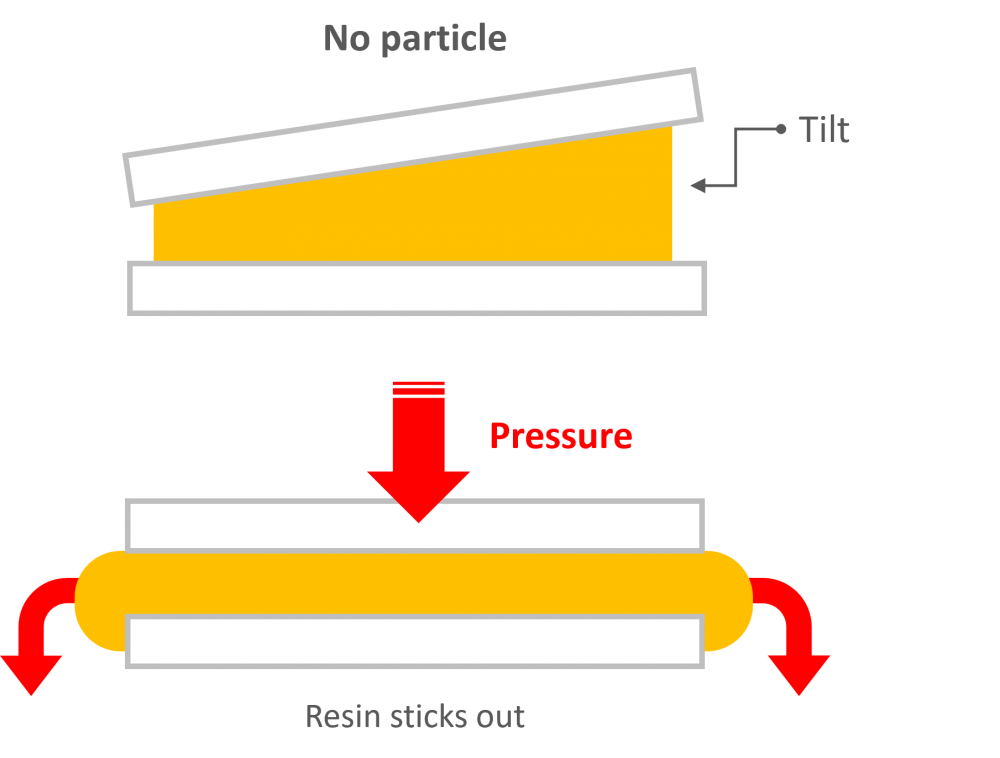

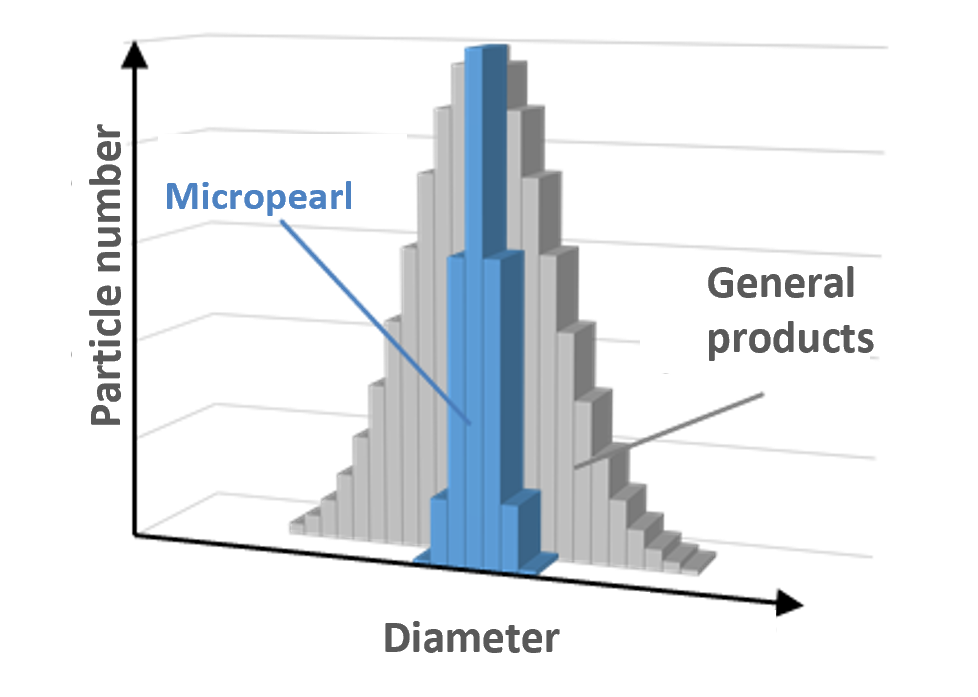

A uniform gap

A uniform gap

・Uniform gap control

・Uniform gap control

Product line

Product line

・Particle size

・15μm ~ 500μ

High reliability

High reliability

・Withstands high temperature environment

・Stable adhesive strength even in a high temperature and high humidity environment

Technical details

A uniform gap

A uniform gap

- Uniform gap control

- Few large particle

No particle

Particle

Product line

Product line

| Av. diameter | Cv [%] |

Grade | Av. diameter | Cv [%] |

|

|---|---|---|---|---|---|

| [μm] | [μm] | ||||

| SP-215 | 15± 0.1 | 5% | GS-L120 | 120± 6 | 7% |

| SP-220 | 20± 0.15 | GS-L150 | 150± 7 | ||

| SP-225 | 25± 0.2 | GS-L200 | 200 ± 10 | ||

| SP-240 | 40± 0.3 | GS-L300 | 300 ± 15 | ||

| SP-250 | 50± 0.5 | GS-L350 | 350 ± 17.5 | ||

| GS-260 | 60± 3.0 | 7% | GS-L400 | 400 ± 20 | |

| GS-280 | 80± 4.0 | GS-L450 | 450± 22.5 | ||

| GS-L100 | 100 ± 5.0 | GS-L475 | 475 ± 22.5 |

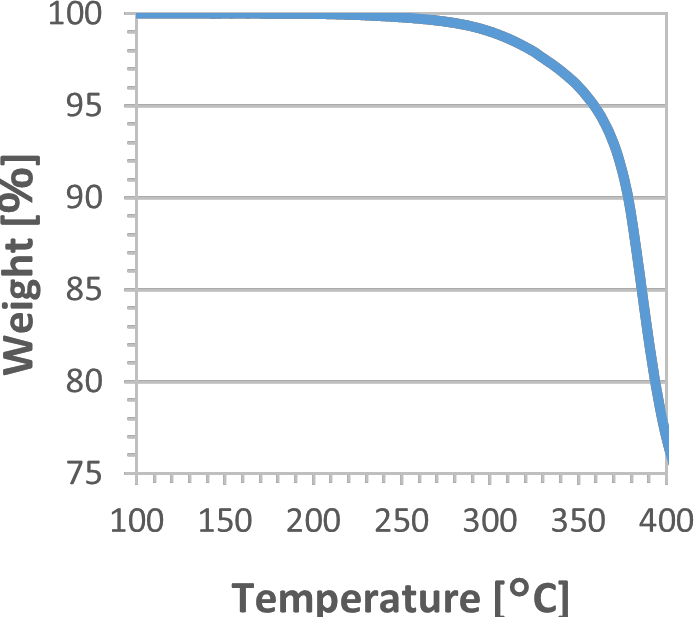

High reliability

High reliability

Pyrolysis

Moisture resistance and heat stability

Characteristics

1The thickness of the adhesive can be precisely controlled

2Effectively maintain the adhesive insulation

3It is conductive to ensure the consistency of adhesive force

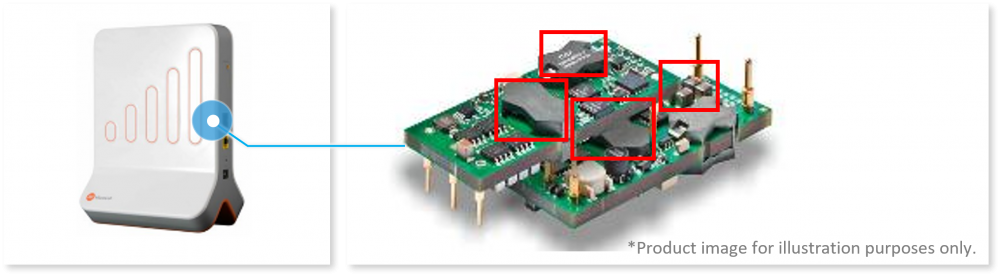

Applications

- Inductors, power supply modules, etc.

Expected effect: stabilization of inductance - Pressure sensor and fixing chip of acceleration sensor

Expected effect: increase the sensor sensitivity - Fixing components in the camera module

Expected effect: Suppression of camera sensor shake

Comparison with current technology

The advantages of our products in gap control

- Process reduction (yield improvement)

- Stable inductance · Reduce tolerance

- Can also be controlled for narrow intervals

- Can be used for ferrite cores of various shapes

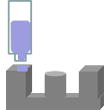

Comparing to existing construction method

Process

Polishing

1.Polishing

2.Thickness

test

3.Dispense

adhesive

4.Bonding

5.Hardening

Tape

1.Punching

(die cutting)

Manual work

2.Bonding

by tape

Manual work

3.Dispense

adhesive

4.Bonding

5.Hardening

Glass

beads

1.Mixing

Required amount

of adhesive and

particles need

to be mixed

in advance

2.Filling

3.Dispense

adhesive

4.Bonding

5.Hardening

Our products

Unnecessary process

1.Dispense

adhesive

2.Bonding

3.Hardening

Particle sizes selection

| Average particle diameter[µm] | Cv |

|---|---|

| 10±0.1 | 5% or less |

| 15±0.1 | |

| 20±0.15 | |

| 25±0.2 | |

| 30±0.25 | |

| 50±0.5 | |

| 75±0.5 | |

| 100±1 | |

| 110±1 |

| Average particle diameter[µm] | Cv |

|---|---|

| 40±2 | 7% or less |

| 50±2.5 | |

| 60±3 | |

| 70±3.5 | |

| 80±4 | |

| 90±4.5 | |

| 100±5.5 | |

| 120±6 | |

| 130±6.5 | |

| 140±7.0 | |

| 150±7.5 | |

| 160±8.0 | |

| 170±8.5 | |

| 180±9.0 | |

| 190±9.5 | |

| 200±10 |

Document download

- All

- Electronics

- Mobility