_導電性粘着テープ 7800シリーズ_png_w500px_h500px.png)

Conductive Adhesive Tape 7800 Series

A strong-adhesion tape for reflow processes that combines high conductivity with heat resistance

This series applies nano-thin film coatings to metal foils and PET films, achieving excellent conductivity, heat resistance, and adhesion. It supports applications such as electrostatic dissipation, grounding, and shielding in electronic devices. With a high reliability design optimized for diverse materials and environments, this series is well-suited for thin devices requiring both heat dissipation and flexibility.

- Electronics

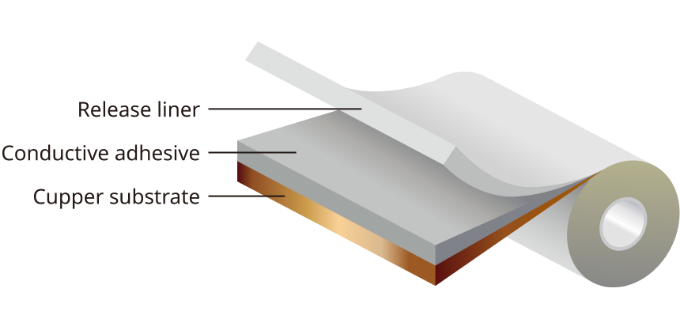

Structure & Features

- Highly reliable with strong adhesion

- Copper foil substrate for low resistance

- Can be used in reflow processes

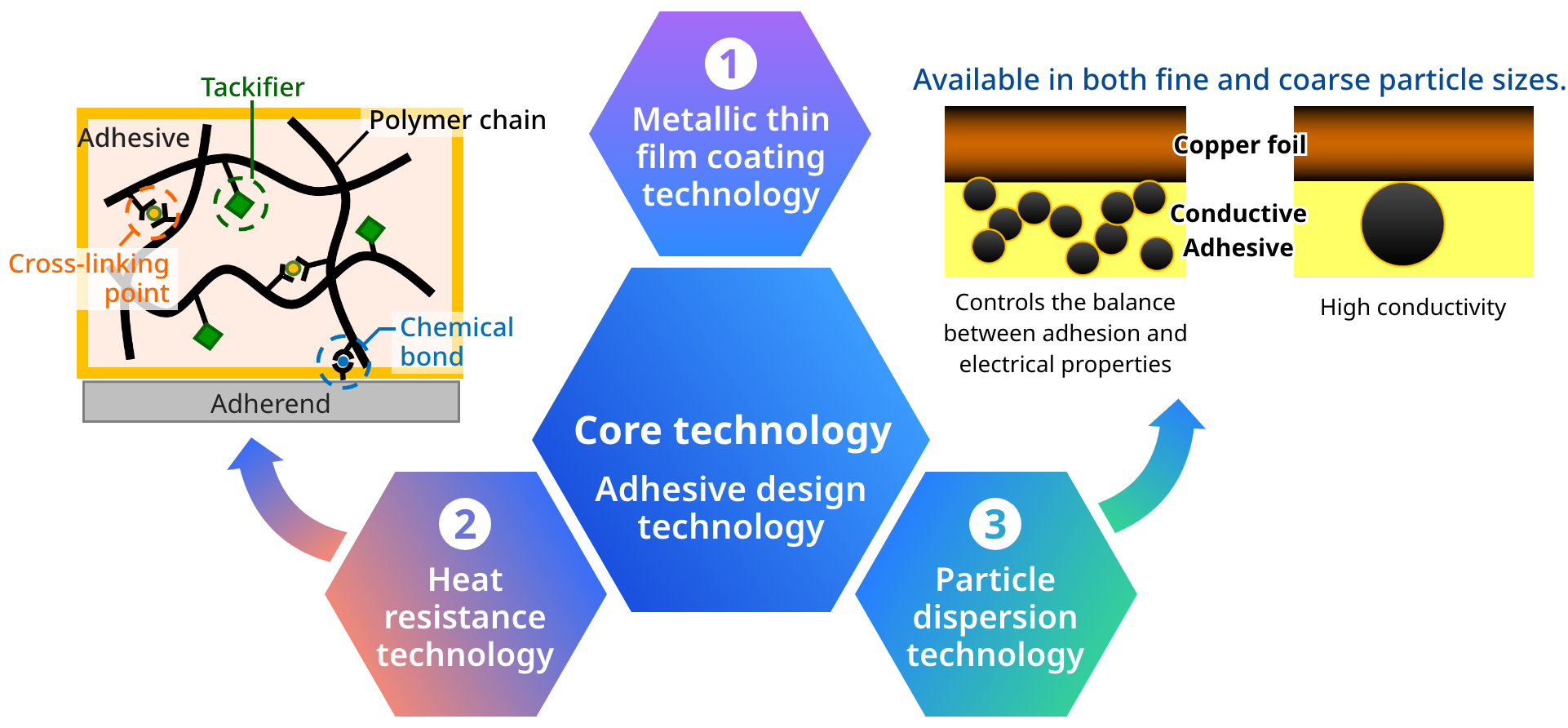

SEKISUI Chemical’s strength: Adhesive design can be made according to the intended use

Metallic thin film coating technology

Metallic thin film coating technology- This series offers a diverse range to fulfill various functionswith a base material of metallic foil, copper foil, non-woven fabric, or PET film and a nano-ordered metallic thin film coating.

(e.g., AI, Cu, Ag, Ti, SUS)

Heat resistance technology

Heat resistance technology- Functions such as high reliability design and heat resistance can be added through control of the adhesive at the molecular level.

Particle dispersion technology

Particle dispersion technology- Not only is an appropriate selection of fillers possible, but also higher conductivity can be achieved by using SEKISUI’s particle dispersion technology.

Features

1Strong adhesion achieves excellent heat resistance and resistance value reduction

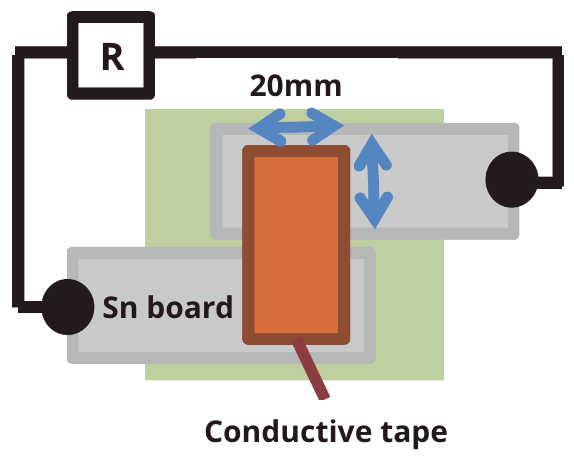

Evaluation method

- Stick conductive tape across two SUS boards.

- Leave in the specified holding temperature.

- Place an electrode on each SUS board and measure the resistance value.

| Attachment area | 20mm × 20mm |

|---|---|

| Holding temperature | 125℃ |

| Measurement time | 1080 hours |

| Measurement conditions | 23℃ × 50%RH |

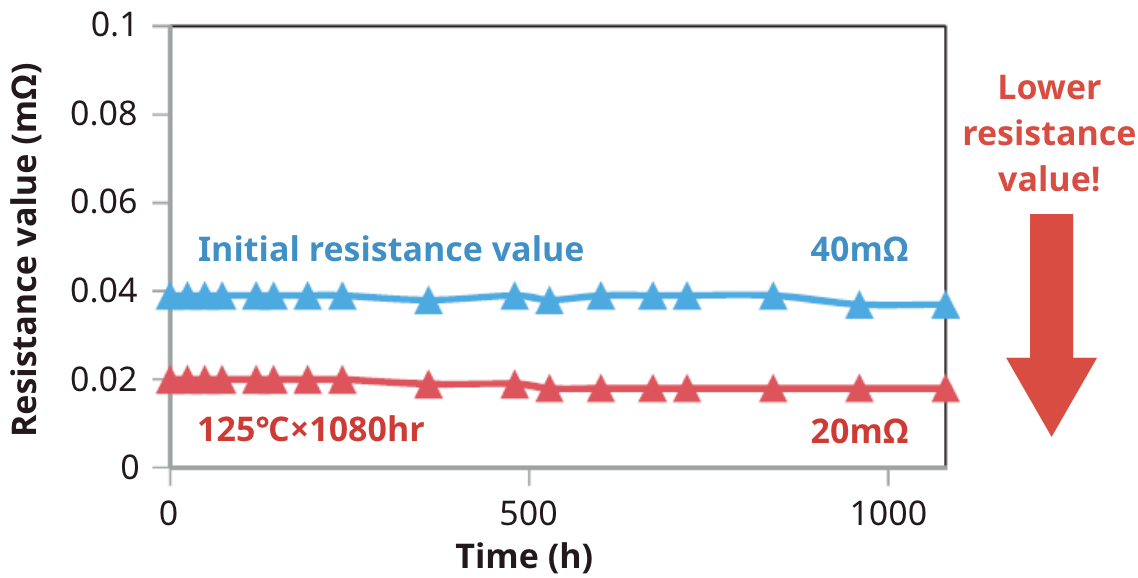

Results

Even in a high temperature environment, wettability of the adhesive layer in the SEKISUI product actually increases, tending to improve electrical properties.

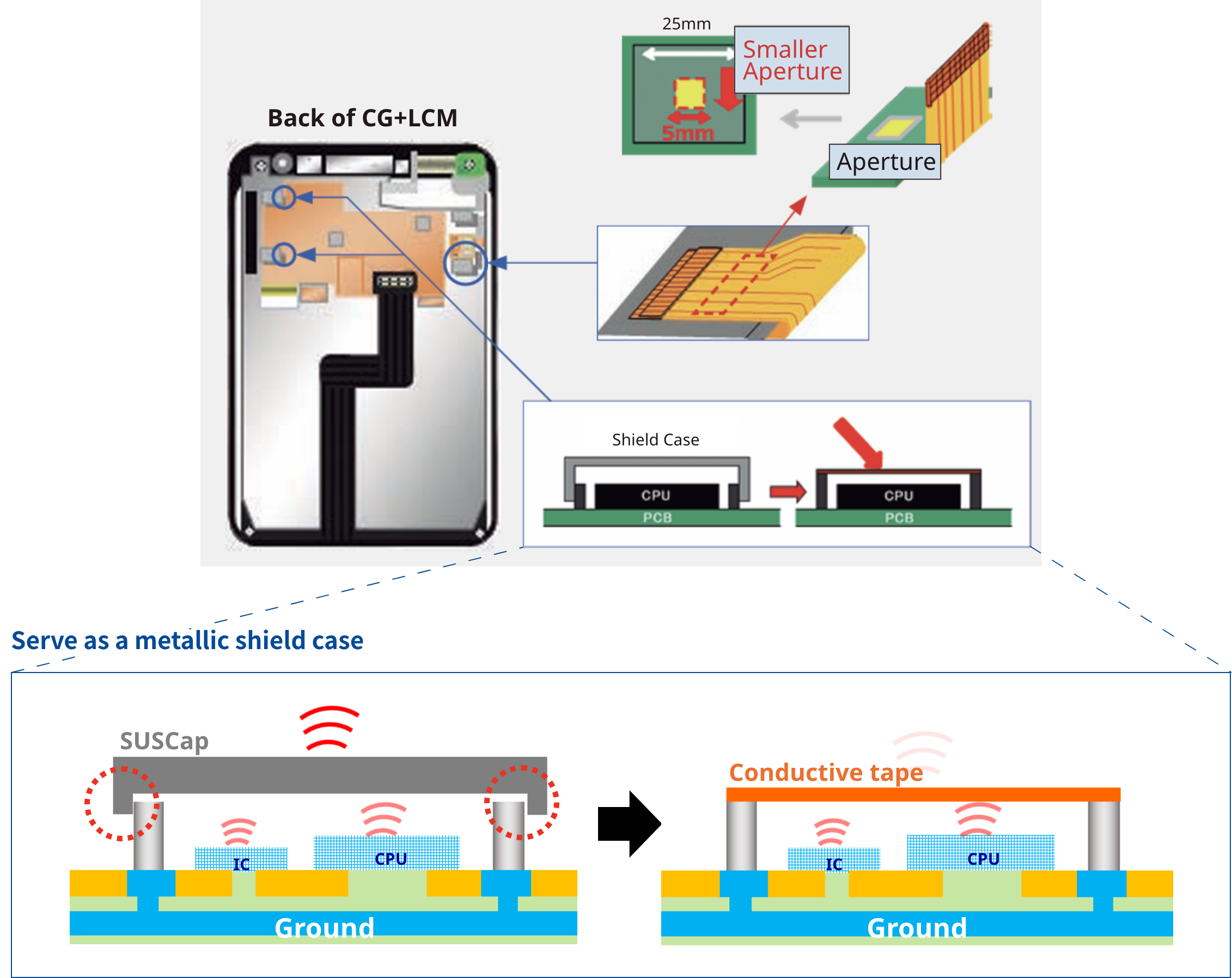

2Strong adhesion provides excellent shielding performance

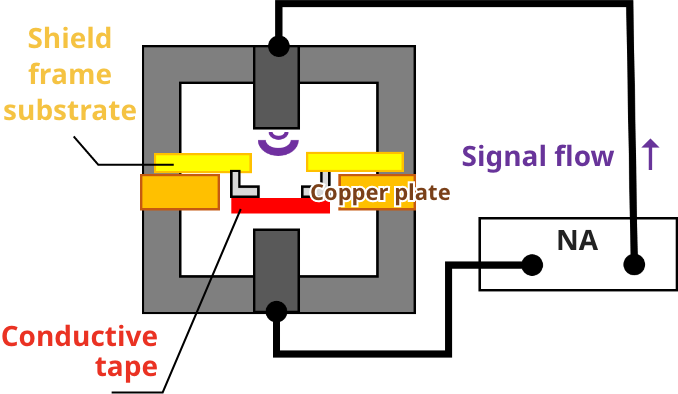

Illustration of measurement

Measure the amount of noise coming from the top of the shield cap and from the joining edge of the frame and the tape.

Evaluation method

*Based on the KEC method that is one type of shield measurement method

- Place a copper plate partition with holes inside a SUS box and stick a sample tape on the copper plate.

- Emit the specified frequency from devices attached to the top and bottom of the SUS box.

- Assess the difference in amount of signal received by each.

| Measurement conditions | 23℃ 50%RH |

|---|---|

| Frequency | 0.1MHz~8GHz |

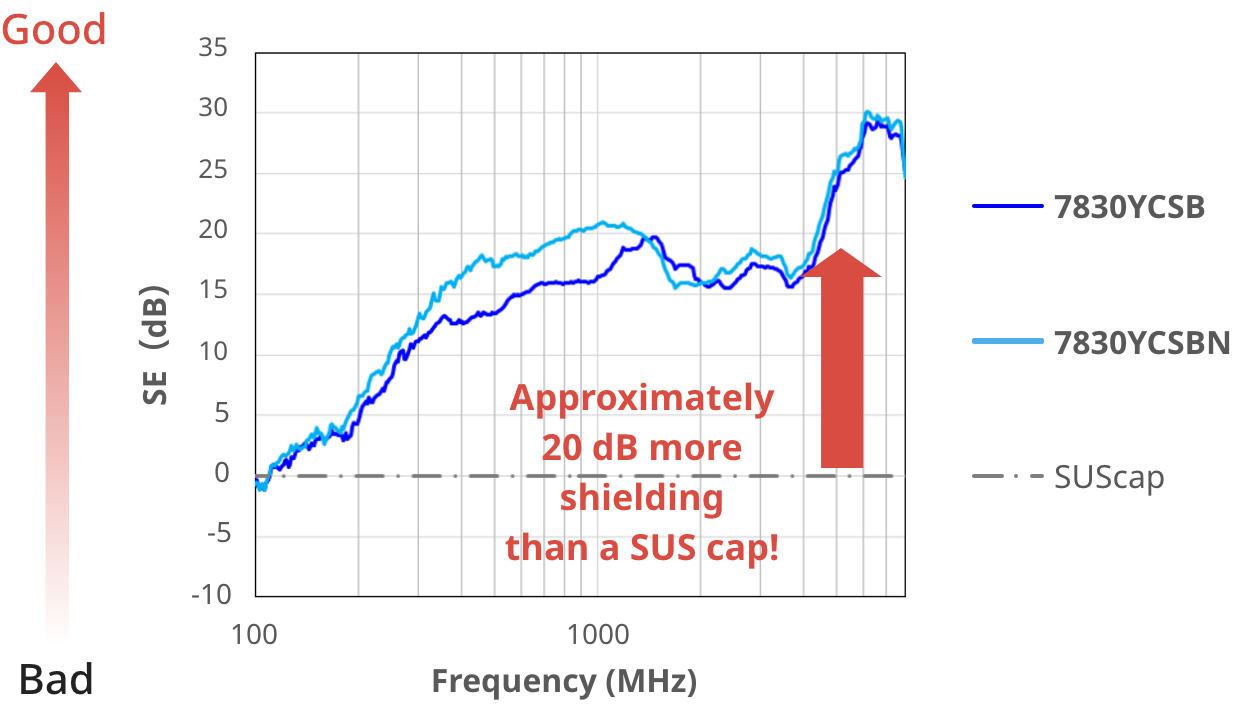

Results

SEKISUI product provide a better shielding performance than SUS caps and competitors’ products and reduce noise and secondary radiation.

Product Lineup

| Series | 7800YCSB | 7800YCWB | ||

|---|---|---|---|---|

| Name | 7830YCSB | 7848YCSB | 7848YCWB | |

| Tape Thickness | 30μm | 48μm | 48μm | |

| Substrate Thickness | 12μm | 18μm | 12μm | |

| Structure |  |

|

||

| Application | GND | ● | ● | ● |

| EMI Shielding | ● | ● | ||

| ESD | ● | ● | ● | |

| Additional Functions | Bending | ● | ||

| Thinner | ● | |||

| Heat Dissipation | ● | ● | ● | |

| Adhesive | 180°JIS Z0237 SUS(N/25mm) | 14 | 19.1 | 13.4 |

| Retention | 85℃*1kg*1hr (mm) | 0 | 0 | 0 |

| XY | Electrical Resistance(mΩ/sq) |

20 | 20 | 20 |

| Z | Tape Size:25mm×25mm Load:500g Cu(mΩ/(25mm□)) |

4 | 8 | 7 |

Applications

This series can be used to block noise from electronic devices.

Are you experiencing these issues?Our sales and technical support team will help you

- Your conductive tape peels off when stuck to small or narrow places

- In high temperature environments, resistance of your conductive tape increases and its electrical properties are unstable