High-magnification foam mold technology

-Challenge- Pursuit of further weight reduction for EVs

-Challenge- Pursuit of further weight reduction for EVs

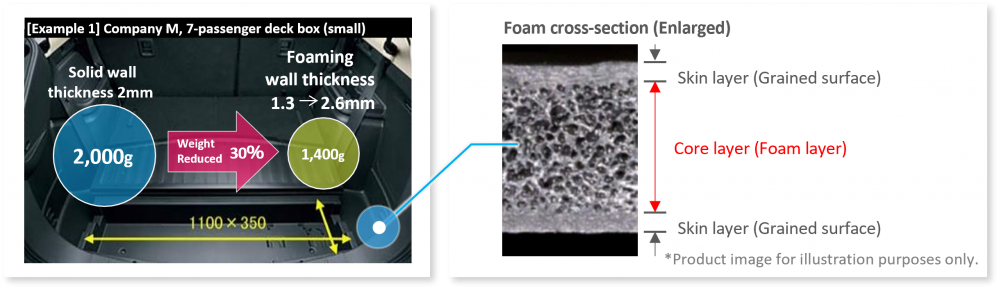

Foamed plastics are increasingly adopted as a material that contributes to energy saving and weight reduction of automobiles.

For instrument panels and door trims, it is required to achieve both light weight as well as texture in terms of surface design and a pleasant feeling to the touch.

-Solution- Lightweight by foaming technology

-Solution- Lightweight by foaming technology

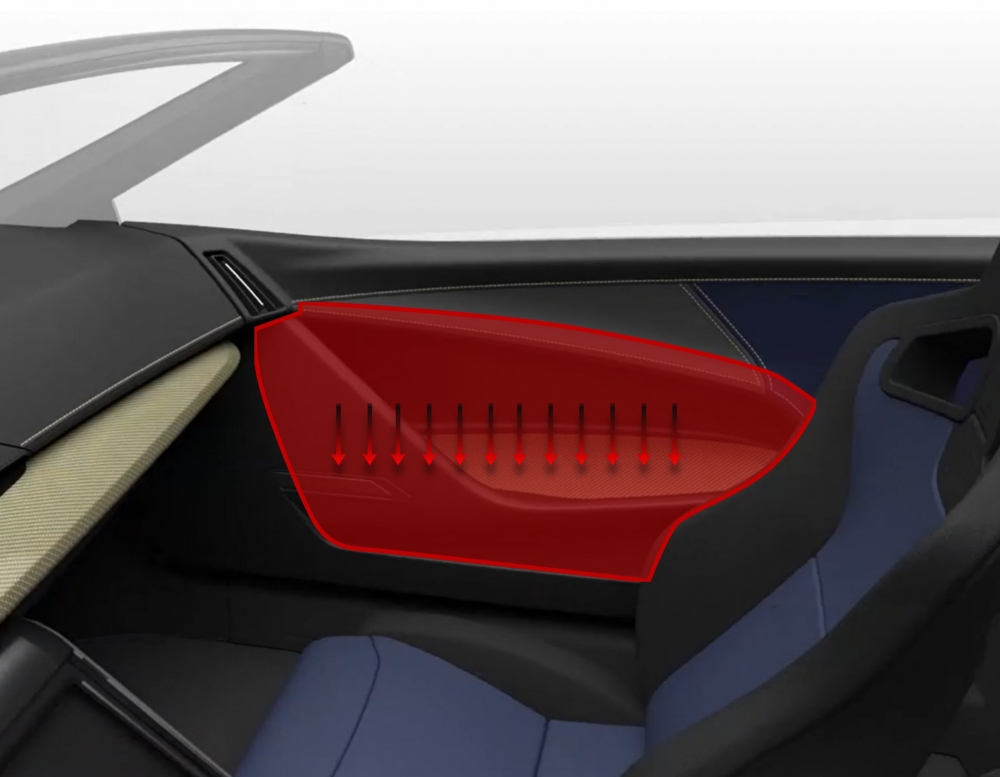

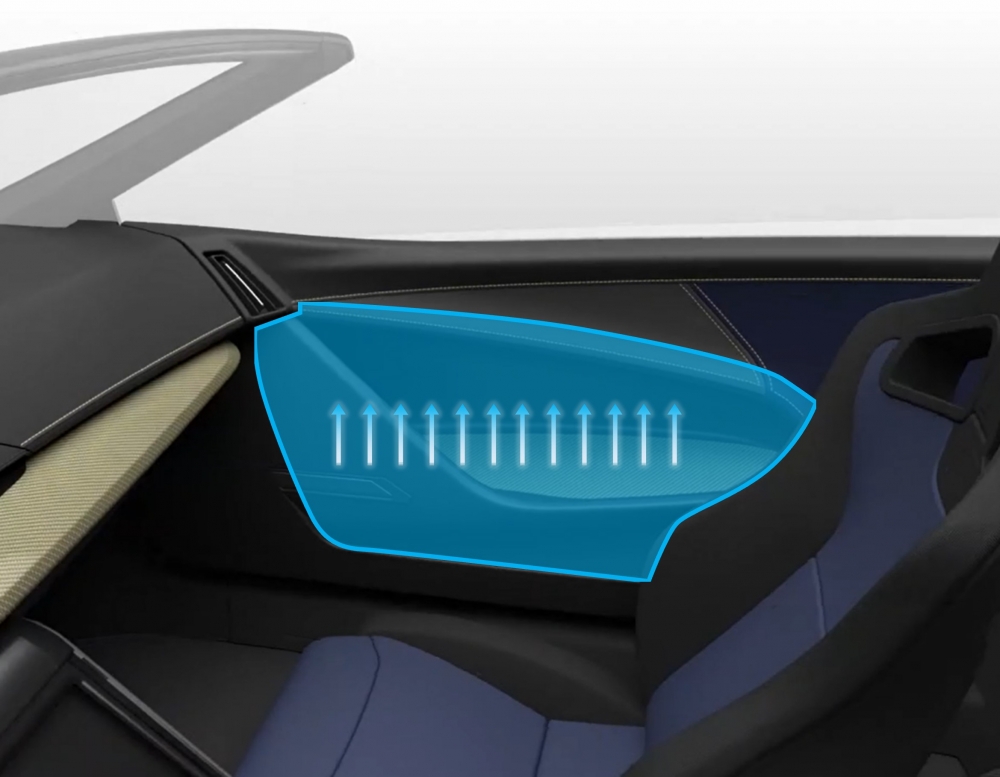

Injection foam molding technology of PP resin is used to form the core (foamed) layer and the skin layer.

SEKISUI’s proprietary technology enables high-aesthetic appeal, high-shock resistance, and high rigidity, while reducing weight by 25-35% compared to solid resin parts.

-Technology- Technical information

-Technology- Technical information

Technical overview

Foam injection mold with all-purpose

Foam injection mold with all-purpose

PP-based compound resin

Injection molding method (Electric motors)

The mold core-back method releases foam components accumulated in the resion to form the core (foaming) layer and skin layer.

Lightweight foam mold

Lightweight foam mold

Automobile interior materials

25~35% weight reduction

Integration of three unique technologies Beautiful appearance,

Integration of three unique technologies Beautiful appearance,

high impact-resistance and rigidity

Fusion of 3 technology

・Material formulation : Appropriate formulation of all-purpose PP resin・Mold/Product design : Uniform filling design・Molding technology : Stabilization of quality

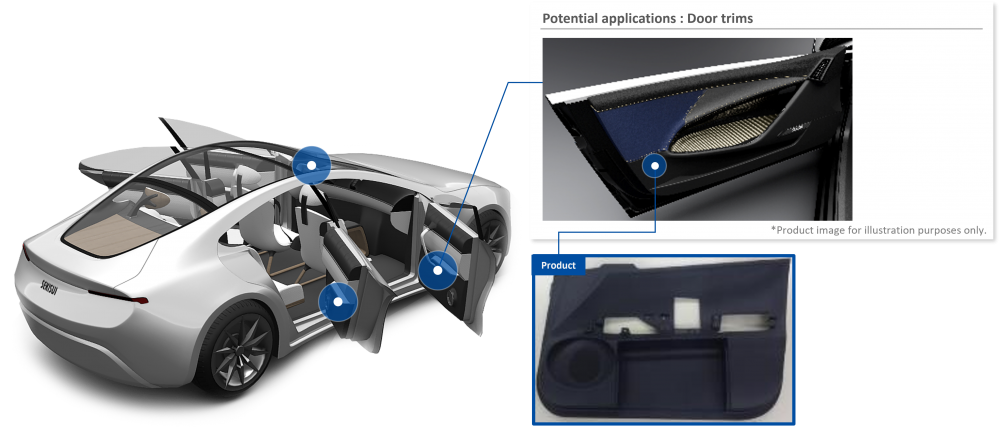

Promising applications

Promising applications

Automobile interior parts, etc.

・Interior trim(Door and deck side)・Luggage box

・Under-seat

Sustainablity

Sustainablity Mobility

Mobility