UV curing adhesive PhotolecS

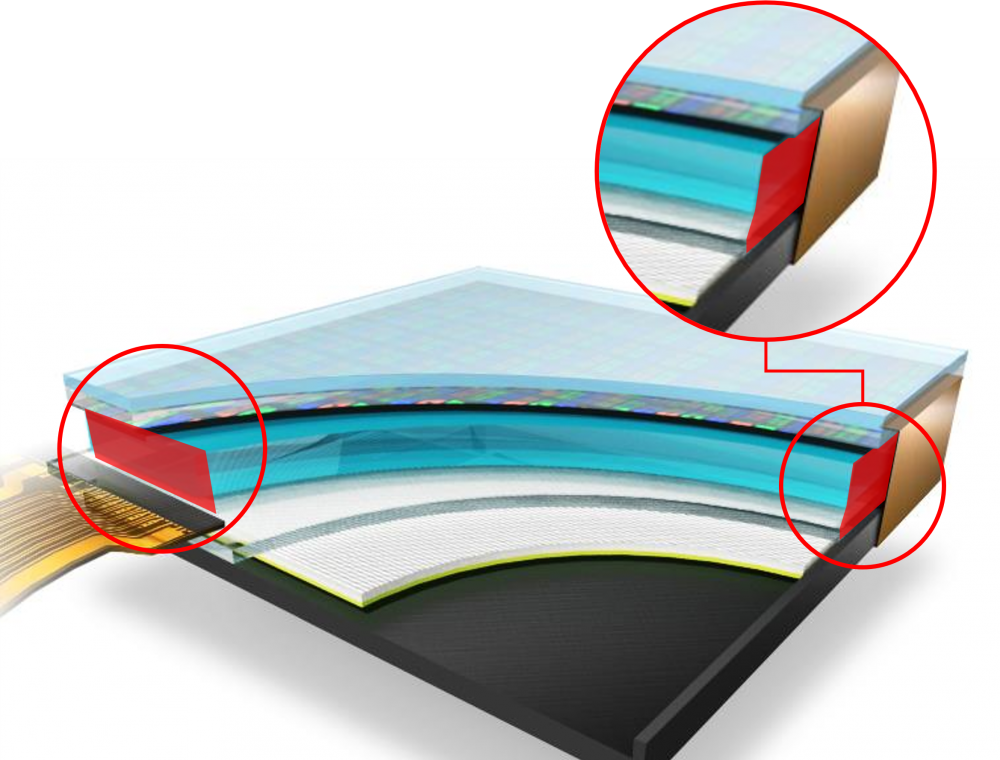

-Challenge- Maintaining sealing performance due to complex panel geometry

-Challenge- Maintaining sealing performance due to complex panel geometry

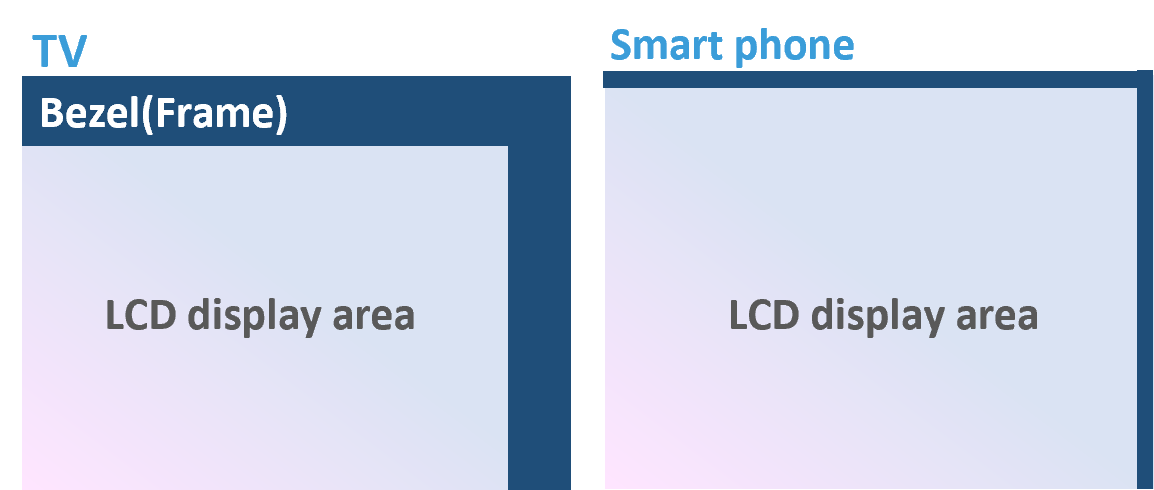

With advanced driver assistance systems (ADAS) continuing to evolve, center information displays (CIDs) now offer entertainment in addition to conventional navigation and air conditioning functions, and the importance of displays is growing as they feature more sophisticated designs and are becoming larger in size.

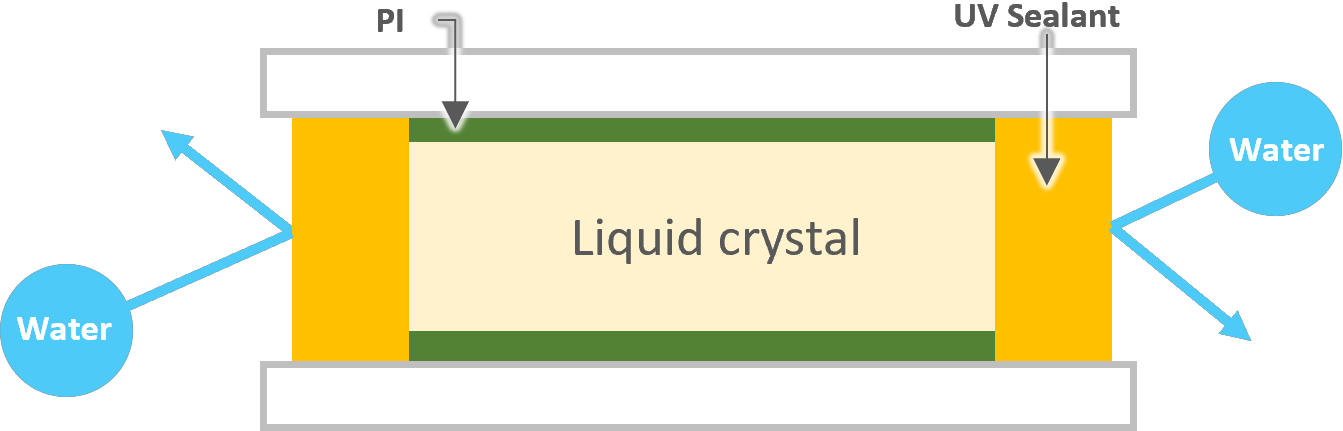

In the production of liquid crystal displays (LCDs) using the one drop fill (ODF) process, there are issues such as the contamination of LCDs by the surrounding sealant, lack of adhesive strength due to the narrower sealing lines associated with narrower panel borders, and poor application performance.

-Solution- Sealant with excellent drawing and adhesive properties

-Solution- Sealant with excellent drawing and adhesive properties

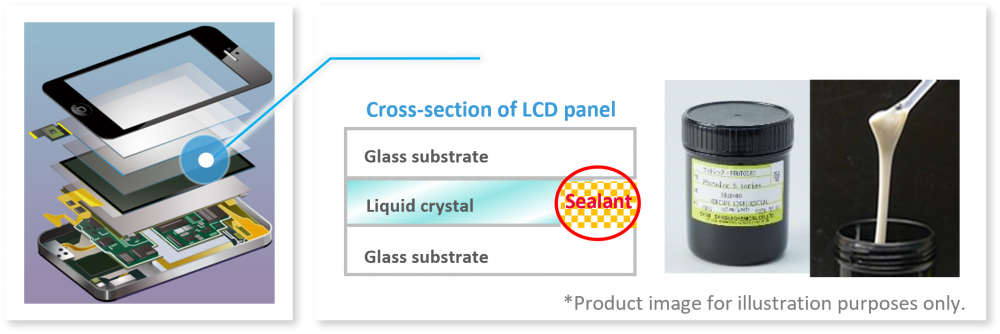

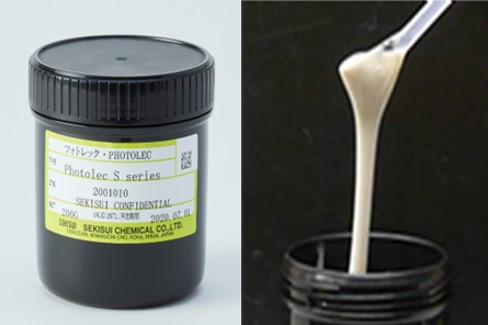

The ODF sealant for LCDs Photolec S, is an adhesive that can be cured with UV and heat, ideal for the ODF method of LCD panel assembly.

It has low elution from resin and high humidity resistance, resulting in low-contamination risk to LCDs.

It offers great workability with a high degree of freedom in dispensing, and strong adhesiveness which enables the narrow side dispensing and panel attaching, and is suited for the narrowing of panel borders.

A wide product lineup and abundant product variations are available.

-Technology- Technical information

-Technology- Technical information

Technical overview

High adhesive strength

High adhesive strength

Strong adhesion

Excellent adhesion for narrower bezel.

Low pollution

Low pollution

Pollution and moisture resistance

Prevent contamination and pollution LC,organic materials(ex PI).

Good workability

Good workability

Excellent drawing

Easy handling and can draw fine line.

Wide product lineup

Wide product lineup

A wide range of products variations

There is also black type & low temperaturecuring type for film substrate.

Technical details

Excellent adhesionOur functional resin technology and adhesive design

Excellent adhesionOur functional resin technology and adhesive design

technology can offer your required adhesive performance.

| Item | Standard | Soft | ||

|---|---|---|---|---|

| Curing conditions |

UV+Heat | 3000mJ/cm2+120℃60min | ||

| Viscosity | 25℃、1rpm | MPa・s280,000230,000 | ||

| Ti | 1rpm/10rpm | -1.151.37 | ||

| W V T R | 60℃90%RH | g/m²3471 | ||

| Shear bond strength |

Glass/Glass | N/25 mm²>500>500 |

||

| Tg | DMA | ℃9545 | ||

Low pollution

Low pollution

moisture resistance, reducing the risk of display defects.

Excellent drawing

Excellent drawing

If it can’t draw, you can’t make LCD panels.

Frequently asked inquiries

Frequently asked inquiries

- 1. Air bubble

- 2. Viscosity is too high to go out

- 3. Drawing line problem

Wide product lineup

Wide product lineup

- ・Beside LCD panels, can be suitable for application such as Lamination of optical lenses

- ・Camera module fixing

- ・μOLED

Document download

認定証ダウンロードファイル一覧

| Name | Type | File | Update | File |

|---|---|---|---|---|

|

Catalog:UV curing adhesive Photolec S_SekisuiMobilitySolution |

Catalog |

2023-09-11 |

Download

1.14 MB

|

Sustainablity

Sustainablity Mobility

Mobility