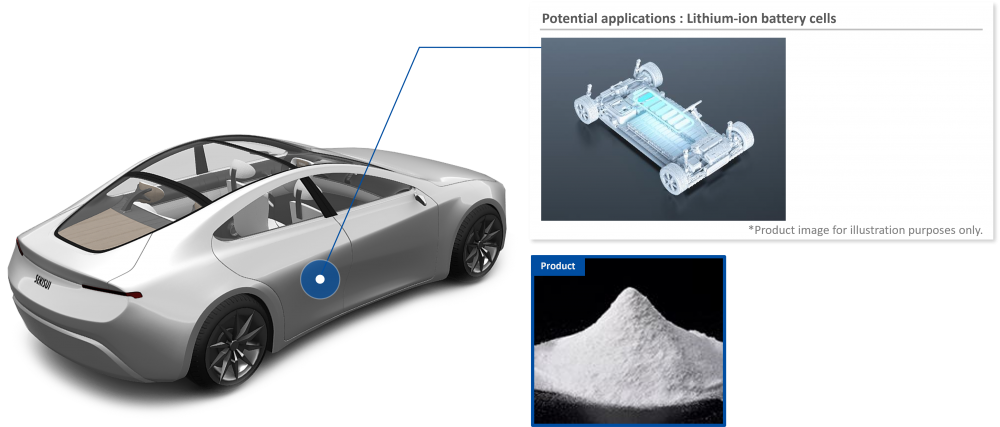

Additive for LiB - PVB Binder Dispersant -

-Challenge- Improved battery characteristics with higher output and capacity

-Challenge- Improved battery characteristics with higher output and capacity

With the increasing capacity of lithium-ion batteries and their expanding use in automotive applications, there is a growing demand for improved battery safety, yet poor dispersibility due to the use of high-viscosity materials and negative effects on cycle characteristics caused by current interruption remain issues. As the electric vehicle (EV) market expands, there is an urgent need to develop materials that can support higher output and higher capacity. Why is it necessary to use high-viscosity materials?

-Solution- PVB resin with excellent adhesion and dispersibility

-Solution- PVB resin with excellent adhesion and dispersibility

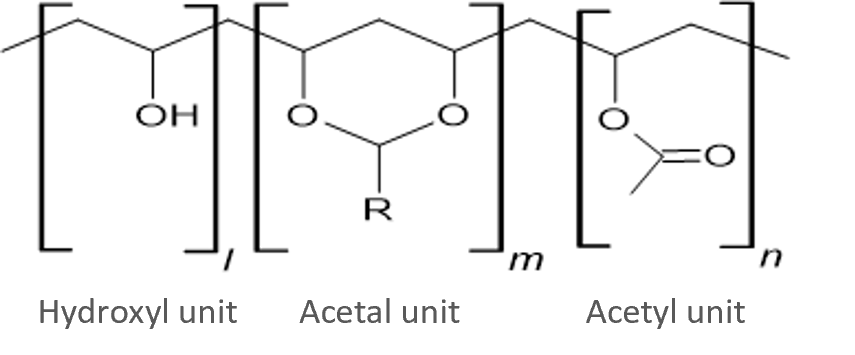

Our product offers excellent adhesion and three times the peel strength of conventional binders. Along with a wide range of organic solvents, it dissolves in water, enabling low-viscosity and high-solidity content even with materials that are difficult to disperse. By contributing to NMP reduction and dispersion stabilization, and by changing the weight ratio of the three chemical units, the chemical and physical properties can be altered. What are the advantages of using this product at cell?

-Technology- Technical information

-Technology- Technical information

Technical overview

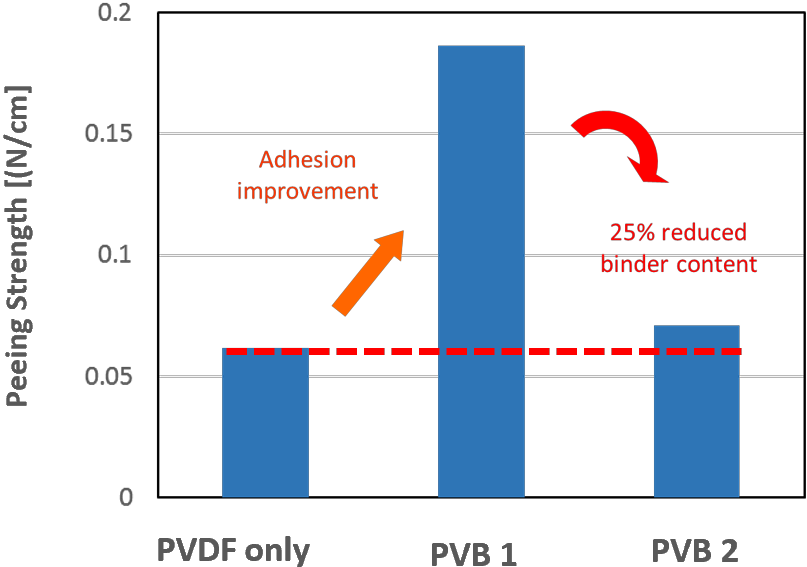

Superior adhesiveness

Superior adhesiveness

Peeling Strength

You can have 3 times peel strength comparing tocurrent binder with superior adhesiveness.

Excellent dispersibility

Excellent dispersibility

Process effective

Low viscosity and high solid differentiationare achieved even with

difficult-to-dispersible materials.

It contributes to reduction of NMP

and stabilization of dispersions.

Solubility

Solubility

Soluble in a wide variety of solvents

Dissolves not only in a wide range oforganic solvents, water as well.

Structure of PVB

Structure of PVB

can be changed to alter the chemical and

physical properties.

Technical details

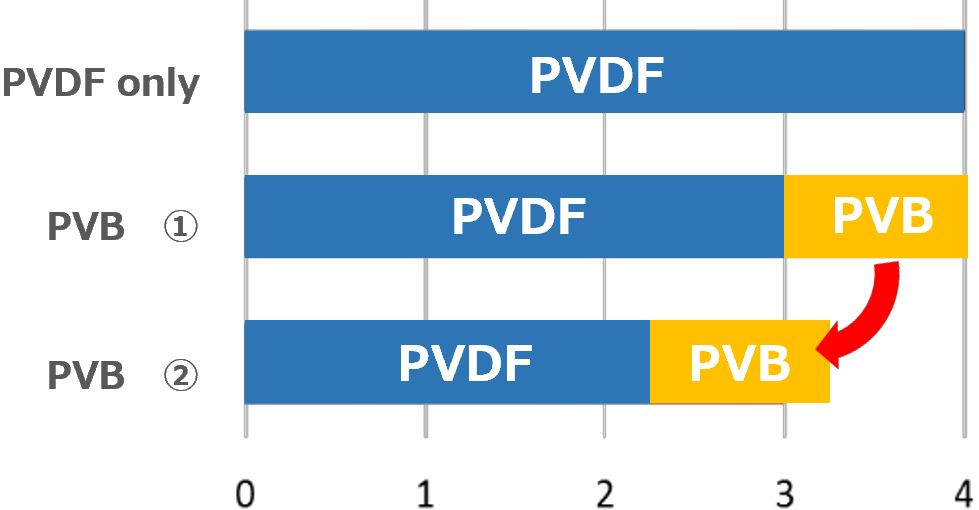

Superior adhesiveness

Superior adhesiveness

Even a small amount of binder is sufficient for full functionality

Adding 25% PVB to PVDF reduces overall 25 % of resin content.Formulation of binder content

Binder content in cathode [wt%]

Binder content in cathode [wt%]Adhesion properties

Optimal materials for high power/high capacity

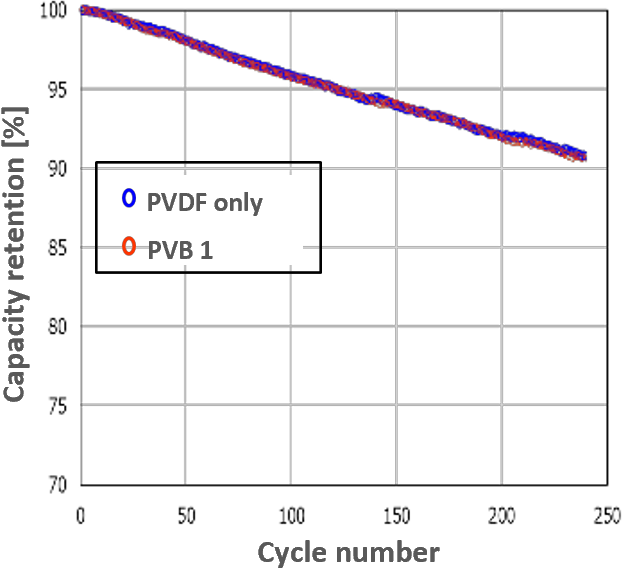

Reduced amount of resin reduces current alienation and contributes to increased concentration of activeand conductive materials without adversely affecting cycle characteristics.

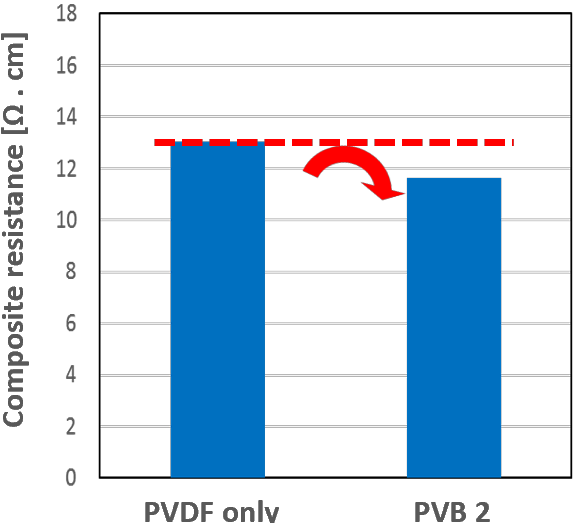

Cathode composite resistivity

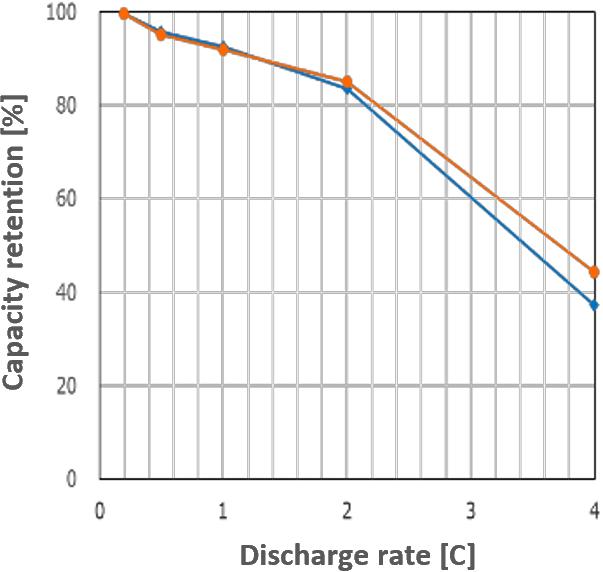

Discharge rate properties

Cycle properties

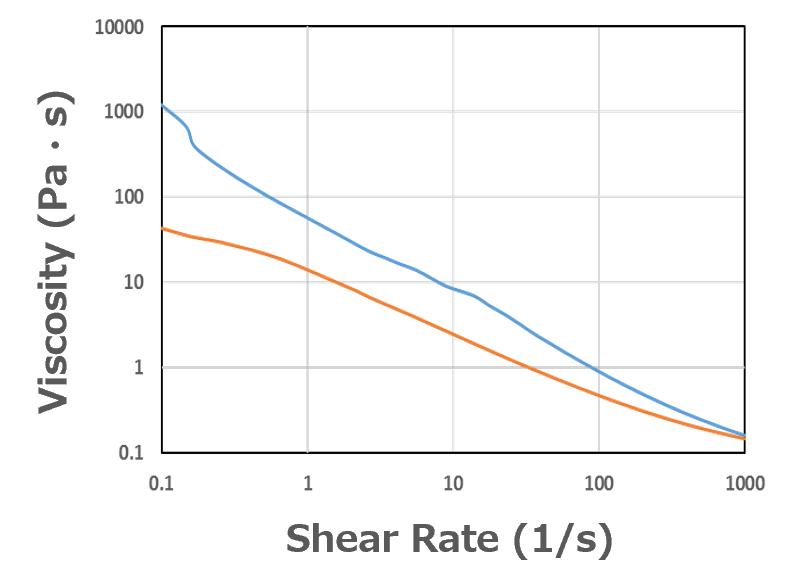

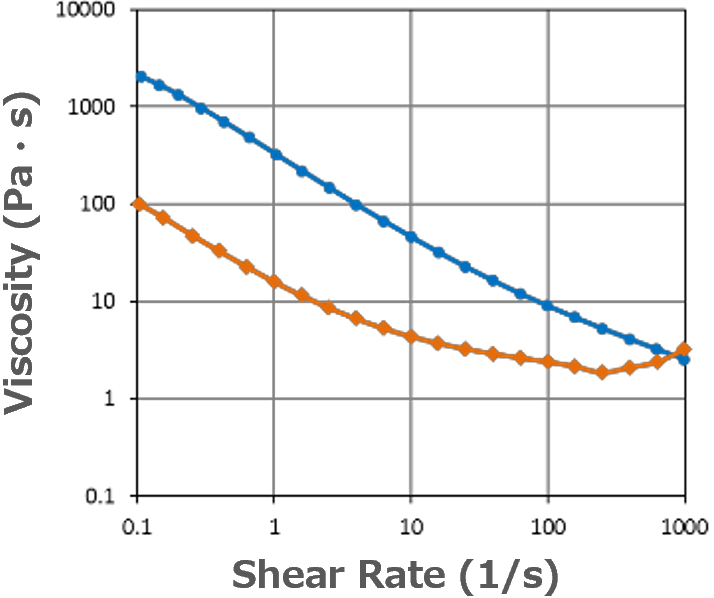

Excellent dispersibilityContribution of lower viscosity and

Excellent dispersibilityContribution of lower viscosity and

higher solid differentiation that affects process cost.

(Viscosity increase rate after 7 days)

| Samples | Solid of content |

Viscosity (Pa . S) | |

|---|---|---|---|

| 1(1/s) | 100(1/s) | ||

| PVDF | 58 | 323.7 | 9 |

| PVDF + PVB | 65 | 15.9 | 2.4 |

Contributes to high solid content, reduces 7% of NMP solution, and shortens drying time

The addition of PVB resin can create a slurry with low viscosity that retains dispersion well.

Document download

認定証ダウンロードファイル一覧

| Name | Type | File | Update | File |

|---|---|---|---|---|

|

Catalog:Additive for LiB - PVB Binder Dispersant -_SekisuiMobilitySolution |

Catalog |

2023-09-11 |

Download

1.24 MB

|

Mobility

Mobility