Polyvinyl Acetal Resin S-LEC B / S-LEC K

Polyvinyl acetal resin (PVB) with excellent physical properties : Toughness, Adhesiveness and Dispersibility

● In addition to general polyvinyl butyral resin, various resins with different structure

and ratio of the acetal group is available.

● By adjusting the ratio of each group and degree of polymerization, it is possible to control

the material properties for various applications.

● Can be used in a wide range of applications such as binders, dispersants and adhesives.

Features

Polyvinyl acetal resin (PVB) exhibits various functions such as toughness, adhesiveness and dispersibility in a balanced manner, and contributes to satisfying the required quality for various applications.

Toughness

Adhesiveness

Dispersibility

Pyrolytic Property

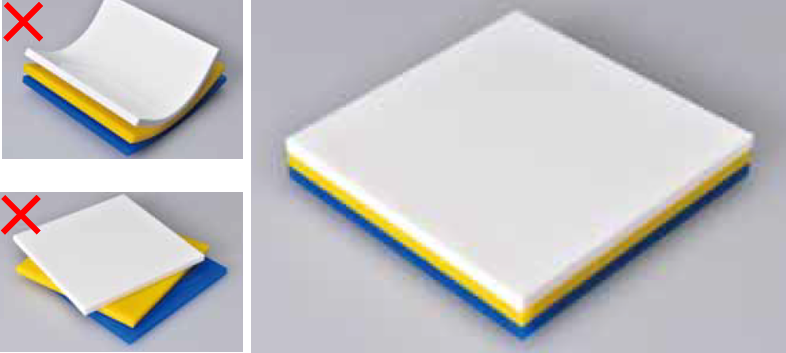

High Temp. Oven Green sheet

High Temp. Oven Green sheet

Solubility/Compatibility

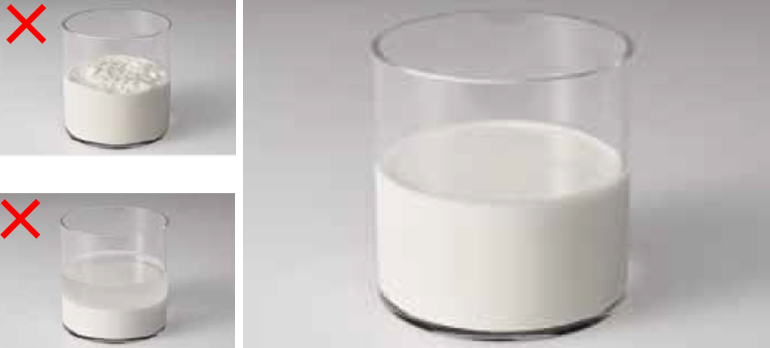

PVB powder

PVB powder

compatible with many solvents and resins.

Transparency

Glass PVB

Glass PVBlayer

- ・Thickening property

- ・Moldability

- ・Insulation

etc …

Applications

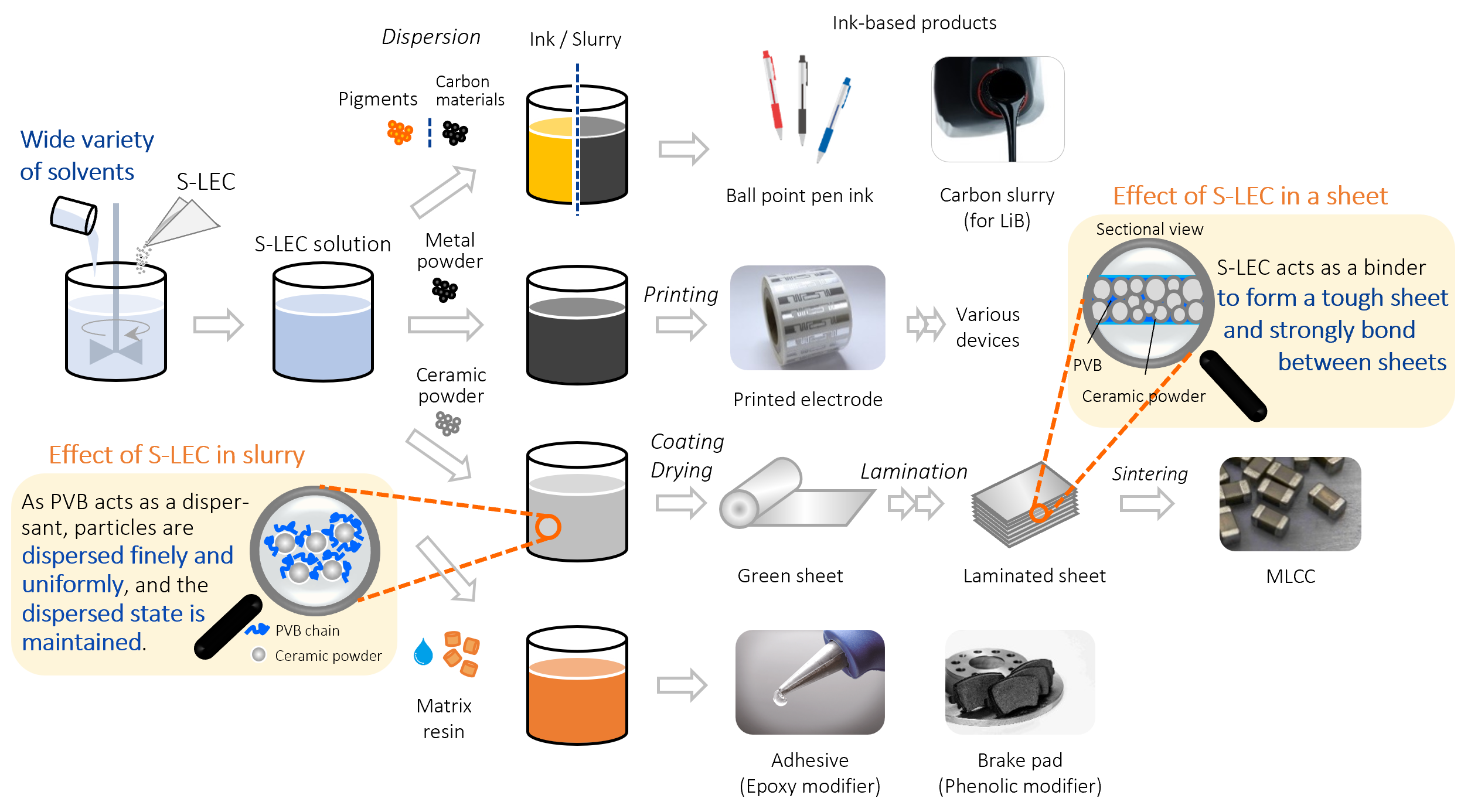

PVB is used in a wide range of applications, including binders for MLCC and other ceramics, binders for conductive pastes, dispersants for pigments and carbon materials, modifiers for epoxy and phenolic resins, inkjet receptive layers, and adhesives and so on.

MLCC

MLCC Other ceramic parts

Other ceramic parts Conductive paste

Conductive paste Paints / Inks

Paints / Inks Resin modifier

Resin modifierHow to Use S-LEC and Its Effects

By dissolving in a solvent suitable for each application and mixing with other materials, the adhesive properties and dispersibility characteristic of S-LEC can be demonstrated in products and their manufacturing processes.

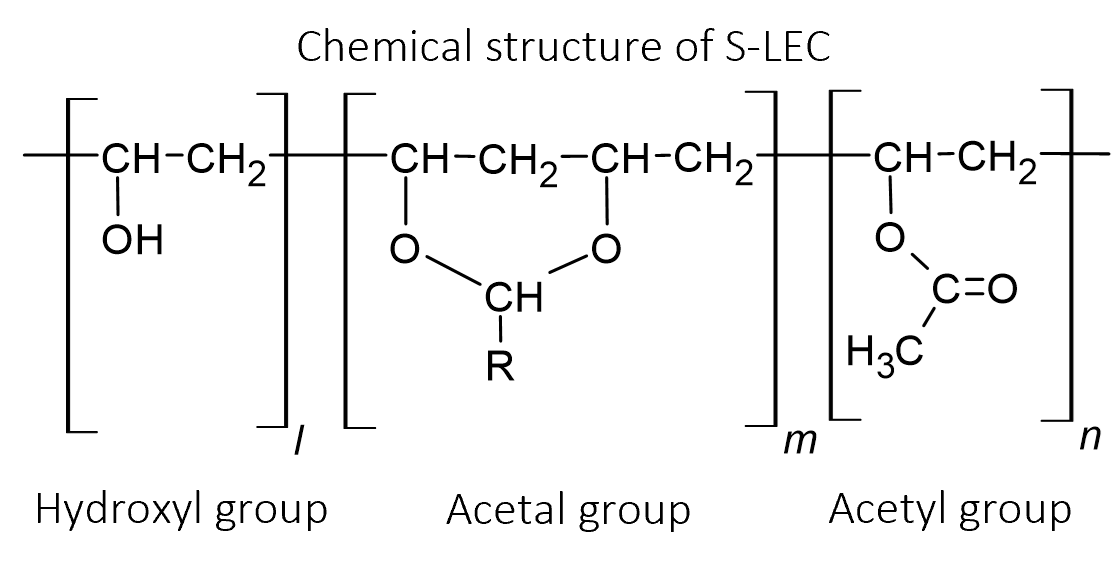

Chemical Structure

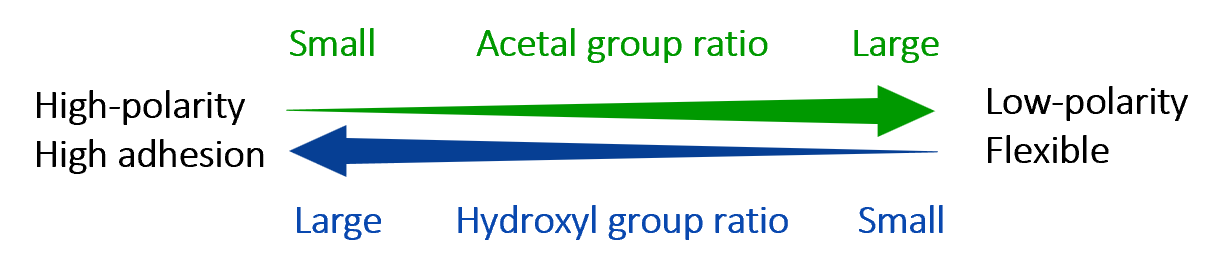

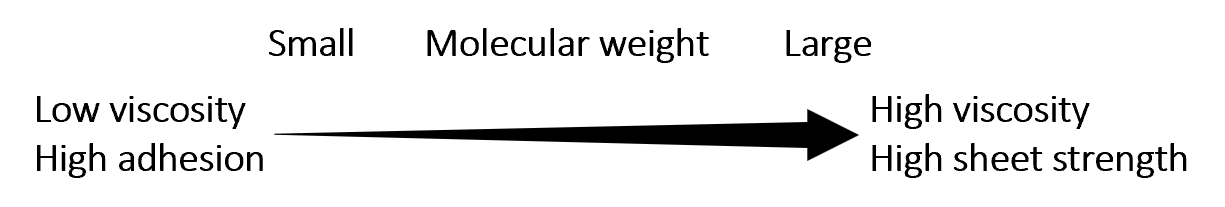

The chemical and physical properties of S-LEC can be controlled by adjusting the molecular weight and the ratio of the three units composing PVB: acetal group, acetyl group and hydroxyl group. This allows us to propose suitable grades with properties that meet your needs.

- ※R= C3H8 : Polyvinyl Butyral

- R= CH3 : Polyvinyl Acetacetal

The above two are collectively called “polyvinyl acetal resin”.

◆ Control of material properties

※We also have a lineup of water-based PVB (S-LEC K KW/KX) with a high hydroxyl ratio.

Specifications

■Product grades

| Grade | Type | Calculated molecular weight ×104 |

Viscosity | Polymer composition | Tg | Volatiles | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5wt% | 10wt% | Hydroxyl content |

Acetyl content |

Acetal content |

|||||||||

| mPa・s | mol% | wt% | mol% | wt% | mol% | wt% | ℃ | % | |||||

| Low molecular- weight |

BL-10 | P | 1.6 | ー | 9 to 15 | c.a.25 | c.a.17 | 4 max | 5 max | c.a.73 | c.a.80 | 67 | 3 max |

| BL-1 | P | 1.9 | ー | 10 to 30 | c.a.33 | c.a.23 | 4 max | 5 max | c.a.66 | c.a.75 | 70 | 3 max | |

| BL-1H | P | 2.0 | ー | 10 to 30 | c.a.27 | c.a.19 | 4 max | 5 max | c.a.72 | c.a.80 | 68 | 3 max | |

| BL-S | P | 2.4 | ー | 10 to 30 | c.a.19 | c.a.13 | 6 max | 7 max | c.a.76 | c.a.81 | 66 | 3 max | |

| BL-2H | P | 2.8 | ー | 25 to 55 | c.a.27 | c.a.19 | 4 max | 5 max | c.a.72 | c.a.80 | 70 | 3 max | |

| BL-5Z | Z | 3.2 | ー | 30 to 50 | c.a.19 | c.a.13 | 4 max | 5 max | c.a.79 | c.a.85 | 67 | 3 max | |

| BL-7Z | Z | 3.9 | ー | 50 to 90 | c.a.28 | c.a.19 | 4 max | 5 max | c.a.71 | c.a.79 | 71 | 3 max | |

| Medium molecular- weight |

BM-1 | P | 4.1 | ー | 60 to 100 | c.a.31 | c.a.22 | 4 max | 5 max | c.a.68 | c.a.77 | 72 | 3 max |

| BM-5 | P | 5.3 | ー | 140 to 220 | c.a.31 | c.a.22 | 4 max | 5 max | c.a.68 | c.a.77 | 73 | 3 max | |

| BM-2(Z) | P/Z | 5.3 | ー | 100 to 170 | c.a.28 | c.a.19 | 4 max | 5 max | c.a.71 | c.a.79 | 71 | 3 max | |

| BM-S(Z) | P/Z | 5.3 | ー | 80 to 150 | c.a.19 | c.a.13 | 6 max | 7 max | c.a.76 | c.a.81 | 67 | 3 max | |

| BM-SHZ | Z | 5.3 | ー | 110 to 190 | c.a.19 | c.a.13 | 4 max | 5 max | c.a.79 | c.a.85 | 68 | 3 max | |

| High molecular- weight |

BH-S | P | 6.7 | 20 to 40 | ー | c.a.19 | c.a.13 | 6 max | 7 max | c.a.76 | c.a.81 | 67 | 3 max |

| BH-6 | P | 9.3 | 40 to 90 | ー | c.a.28 | c.a.19 | 4 max | 5 max | c.a.71 | c.a.79 | 73 | 3 max | |

| BH-3(Z) | P/Z | 10.8 | 60 to 120 | ー | c.a.31 | c.a.22 | 4 max | 5 max | c.a.68 | c.a.77 | 74 | 3 max | |

| BH-A | P | 11.6 | 35 to 65 | ー | c.a.20 | c.a.13 | 1 max3 | 7 max | c.a.67 | c.a.70 | 65 | 3 max | |

| Heat-resistant type |

BX-L | P | 1.8 | ー | 10 to 30 | c.a.33 | c.a.25 | 4 max | 5 max | c.a.66 | c.a.74 | 95 | 3 max |

| BX-1 | P | 9.8 | 70 to 140 | ー | c.a.31 | c.a.24 | 4 max | 5 max | c.a.68 | c.a.75 | 95 | 3 max | |

| BX-5(Z) | P/Z | 13.7 | 130 to 200 | ー | c.a.29 | c.a.22 | 4 max | 5 max | c.a.70 | c.a.77 | 92 | 3 max | |

| High heat- resistant type |

KS-10 | P | 1.8 | ー | 10 to 30 | c.a.16 | c.a.13 | 4 max | 5 max | c.a.83 | c.a.86 | 105 | 3 max |

| KS-1 | P | 3.2 | ー | 65 to 95 | c.a.16 | c.a.13 | 4 max | 5 max | c.a.83 | c.a.86 | 107 | 3 max | |

| KS-6Z | Z | 11.1 | 110 to 170 | ー | c.a.15 | c.a.12 | 4 max | 5 max | c.a.84 | c.a.87 | 113 | 3 max | |

| KS-5Z | Z | 13.4 | 210 to 270 | ー | c.a.15 | c.a.12 | 4 max | 5 max | c.a.84 | c.a.87 | 113 | 3 max | |

- Note

- Type : P = Powder, Z= Granule

- Viscosity : Ethanol / Toluene = 1/1 solution ( B-type viscometer / 20ºC)

- ※The above values are reference values, not guaranteed values.

■Solubility

| Grade | BL-1 | BL-2H | BL-5Z | BL-10 | BM-1 | BM-2 | BM-S | BH-3 | BH-A | BX-L | BX-5 | KS-6Z | KS-10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alcohol | Methanol | S | S | I | S | S | S | I | S | S | S | S | S | S |

| Ethanol | S | S | S | S | S | S | S | S | S | S | S | I | S | |

| 1-Propanol | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| 2-Propanol | S | S | S | S | S | S | S | PS | S | S | I | I | I | |

| 1-Butanol | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| 1-Octanol | S | S | S | S | S | S | S | PS | S | S | S | I | S | |

| Ethylene glycol | I | I | I | I | I | I | I | I | I | I | I | I | I | |

| Ketone | Acetone | S | S | S | S | I | S | S | I | S | S | PS | S | S |

| Methyl ethyl ketone | S | S | S | S | S | S | S | PS | S | S | S | S | S | |

| Methyl Isobutyl ketone | I | I | S | S | I | I | S | I | S | I | I | I | I | |

| Cyclohexanone | S | S | S | S | S | S | S | PS | S | S | S | S | S | |

| Amide | Dimethylacetamide | S | S | S | S | S | S | S | S | S | S | S | S | S |

| NN,N-Dimethylformamide | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| N- Methylpyrrolidone | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| Ester | Methyl acetate | I | S | S | S | I | S | S | I | S | S | S | S | S |

| Ethyl acetate | I | S | S | S | I | S | S | I | S | PS | S | S | S | |

| n-Butyl acetate | I | I | S | S | I | I | S | I | S | PS | PS | PS | S | |

| 1,3-Butylene glycol diacetate | I | I | S | S | I | I | S | I | PS | I | PS | PS | S | |

| Ether | 1,4-Dioxane | S | S | S | S | S | S | S | PS | S | S | S | S | S |

| Tetrahydrofuran | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| Hydrocarbon | Toluene | I | I | S | S | I | I | S | I | I | I | I | I | I |

| Xylene | I | I | S | I | I | I | I | I | I | I | I | I | I | |

| Hexane | I | I | I | I | I | I | I | I | I | I | I | I | I | |

| Others | Ethylcellosolve | S | S | S | S | S | S | S | S | S | S | S | S | S |

| Dimethyl sulfoxide | S | S | PS | S | S | S | PS | S | S | S | S | S | S | |

| Acetic acid | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| Terpineol | S | S | S | S | S | S | S | PS | S | PS | S | I | S | |

| Butyl carbitol | S | S | S | S | S | S | S | PS | S | S | S | S | S | |

| Butyl carbitol acetate | I | PS | S | S | I | I | S | I | PS | I | PS | PS | S |

- ※Resin concentration : 5 wt%

- ※Solubility: S (Soluble), PS (Partially Soluble), I (Insoluble)

※Please refer to the catalog for other material properties.

S-LEC has other excellent features and is used in many applications.

For more information, please visit the product details page below.

Document download

認定証ダウンロードファイル一覧

Mobility

Mobility